How to Choose the Best Water Treatment Chemicals for Cooling Towers

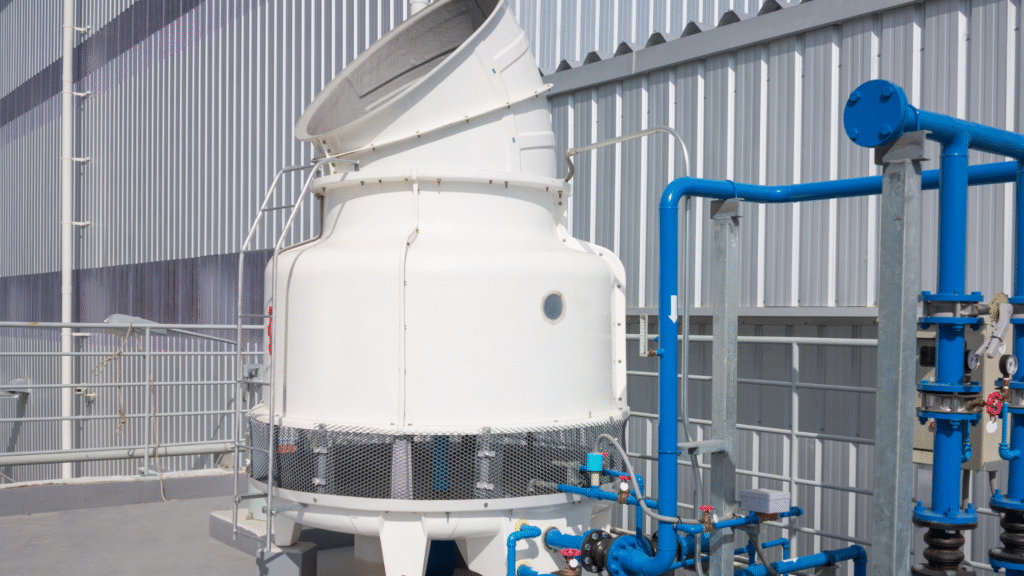

Cooling towers are the workhorses behind many critical operations, from air conditioning in commercial buildings to heat rejection in power plants, food processing plants, and other industrial facilities. These systems remove waste heat by circulating water through a process of evaporation and airflow, helping regulate temperature and maintain productivity across countless industries.

But while cooling towers handle a significant heat load, they are also vulnerable. Without proper treatment, water inside a cooling tower system can accumulate harmful contaminants, scale, corrosion, and biological growth. These issues reduce heat transfer efficiency, increase operating costs, and in some cases, create health risks such as the spread of Legionella bacteria.

That is why choosing the right water treatment chemicals is critical. Proper chemical programs prevent scaling and fouling, control microbiological activity, and extend the life of the entire system. The challenge is that every cooling tower is unique, influenced by its design, industry, and environmental conditions. Selecting the most effective solution requires understanding not only the chemical categories available but also the performance goals of the facility.

This article will guide you through the key considerations when selecting water treatment chemicals for cooling towers, explaining how they work, what factors matter most, and how a well-designed program can keep your system operating at peak efficiency.

Understanding How Cooling Towers Work

A cooling tower system is designed to manage large amounts of heat energy by using water as the primary medium for heat rejection. When a process or an HVAC system generates waste heat, hot water is directed into the tower. Inside, the water flows across fill media in thin sheets, increasing the surface area exposed to air. Fans then pull air upward through the structure, creating direct contact between air and water. This process allows latent heat to be released as a small portion of water evaporates, cooling the remaining circulating water.

Key factors influence cooling tower performance:

- Wet bulb temperature: The lowest achievable temperature using evaporative cooling, which sets a natural limit for system efficiency.

- Delta cooling towers and large cooling towers: Designed to handle higher capacities and significant heat loads from industrial processes like power plants, petrochemical plants, and food processing plants.

- Tower basin: The reservoir where cooled water collects before being pumped back into the system.

- High exiting air velocities: Help drive moisture and heat out of the tower but require proper drift eliminators to prevent water droplets from escaping.

When designed and operated correctly, a cooling tower delivers reliable heat transfer, ensuring that warm water becomes cooled water ready to return to heat exchangers or air conditioning systems. The result is an efficient process that supports industrial production, comfort cooling, and energy savings across other industrial facilities.

Why Water Treatment is Critical for Cooling Towers

Although cooling towers are built for durability, they operate in challenging environments where water, air, and heat converge. As water flows through the system, it inevitably collects dissolved solids and other impurities. Over time, this creates several operational risks:

- Scaling: Mineral buildup restricts water movement, reduces flow rate, and lowers heat transfer efficiency.

- Corrosion: Metal components exposed to untreated water can become highly corrosive, weakening structural integrity and raising maintenance costs.

- Biological growth: Warm, moist environments encourage algae, bacteria, and fungi. If left unchecked, this growth can impair filter performance, foul surfaces, and create conditions for dangerous pathogens like Legionella bacteria.

- Foaming and drift loss: Uncontrolled foam or water droplets escaping the tower can cause chemical imbalances, bleed off, and wasted resources.

These challenges directly affect operating costs. A tower running with scale, corrosion, or microbial contamination uses more energy, consumes more water, and struggles to reach the highest efficiency possible. Seasonal factors such as cold weather can further complicate operations by changing water balance and increasing the risk of equipment stress.

Effective water treatment programs address these risks by maintaining clean water conditions, reducing downtime, and ensuring efficient performance. For facilities that depend on uninterrupted cooling, water management is not optional; it is essential to the long-term health of the entire system.

Also Read: Benefits of Chemical Dosing Pumps in Water Treatment

Categories of Water Treatment Chemicals for Cooling Towers

Choosing the right water treatment chemicals begins with understanding the main categories and how each one protects a cooling tower system. Each tower has unique requirements based on its design, make up water quality, and operating conditions, but these chemical groups form the foundation of effective treatment.

1. Corrosion Inhibitors

Corrosion occurs when water and oxygen attack metal surfaces inside the tower, piping, or condenser water systems. Left untreated, corrosion produces leaks, equipment damage, and unsafe conditions. Corrosion inhibitors slow this process by forming protective films over metal surfaces. Common examples include zinc salts, silicates, and phosphonates, which shield equipment from highly corrosive environments. Preventing corrosion ensures longer service life for heat exchangers, pumps, and the entire system.

2. Scale Inhibitors and Dispersants

Scaling results from the precipitation of minerals like calcium carbonate and silica. As water flows through the tower and cycles concentrate, scale deposits can form on heat exchange surfaces, restricting water passage and lowering heat transfer. Treatment chemicals such as phosphoric acid and polymer-based dispersants prevent minerals from crystallizing, keeping surfaces clean. Managing dissolved solids also supports higher cycles of concentration, which reduces make up water demand and helps facilities save energy and water.

3. Biocides and Algaecides

A cooling tower’s warm, moist conditions promote biological growth. Left unchecked, algae and bacteria form biofilms that insulate surfaces, increase flow rate resistance, and harbor pathogens such as Legionella bacteria. Biocides and algaecides disrupt this growth. Oxidizing biocides, like chlorine or bromine, provide fast, broad-spectrum control, while non-oxidizing biocides target resistant organisms. A balanced program prevents fouling and safeguards worker health.

4. pH and Alkalinity Adjusters

Maintaining stable pH is critical for system stability. Water that is too acidic can become highly corrosive, while overly alkaline conditions promote scaling. pH adjusters, such as sulfuric acid or sodium hydroxide, maintain balance in circulating water. Alkalinity control ensures compatibility with equipment, whether in field erected towers for industrial processes or compact systems in hvac systems.

5. Anti-Foam Agents and Specialty Cleaners

In some systems, surfactants and organics cause foam, reducing performance and increasing drift loss. Anti-foam agents minimize foam formation, protecting drift eliminators and keeping water balance stable. Specialty cleaners help remove fouling, deposits, and other residues from tower water, ensuring efficient performance and preventing downtime.

Factors to Consider When Choosing Treatment Chemicals

While the categories of water treatment chemicals are well established, the right choice for a facility depends on many interrelated factors. Each cooling tower operates under unique conditions, and treatment programs must be tailored to deliver the highest efficiency at the lowest cost.

1. System Design

The type of cooling tower dictates chemical demand. Natural draft and forced draft towers rely on different airflow patterns, while induced draft and counterflow design systems have unique water-to-air contact zones. Delta cooling towers and field erected towers manage larger volumes, requiring higher-capacity programs. Details such as fill media, surface area, falling water in thin sheets, and drift eliminators also affect chemical performance.

2. Operational Conditions

Performance is shaped by how the tower is run day to day. Facilities must evaluate the heat load, flow rate, and variable flow requirements, as well as seasonal challenges. For example, cold weather can destabilize balance, while dry air conditions increase evaporation. Understanding how hot water enters, how much heat is absorbed, and how cooled water exits ensures that chemical feed is properly matched to system demand.

3. Site and Industry Context

Cooling towers in power plants, petrochemical plants, food processing plants, and other industrial facilities all face distinct challenges. Process water in petroleum refining may be more aggressive than condenser water in an air conditioning system. Treatment must be selected accordingly.

4. Performance Goals

Finally, chemical programs should align with long-term goals: reducing water consumption, protecting equipment, extending entire system lifespan, and helping facilities save energy. Choosing the correct blend supports regulatory compliance, efficient operation, and reliable output across industries.

EAI’s Role in Cooling Tower Water Treatment

For more than three decades, EAI has specialized in helping facilities operate cooling towers with maximum efficiency and reliability. Our approach goes beyond simply adding treatment chemicals; we design Total Water Management Programs that integrate chemistry, equipment, automation, and people-driven service.

Low-Dose, High-Performance Chemistry

EAI formulates custom water treatment chemicals designed to work at low doses, which reduces chemical use, supports higher cycles, and minimizes environmental impact. These formulations include corrosion inhibitors, dispersants, biocides, pH adjusters, and detergents, all blended to control scale, fouling, and biological growth while keeping operating costs low.

Remote Monitoring and Preventive Service

Our certified water technologists (CWTs) combine onsite testing with advanced monitoring tools. This allows us to optimize conductivity, make up water cycles, and chemical dosing. Automated systems further reduce downtime by detecting issues early and ensuring treated water maintains balance across the entire system.

Compliance and Safety Support

From Legionella risk assessments to training programs for operators, we make sure facilities maintain both efficiency and compliance. Whether working with HVAC systems, industrial processes, or field erected towers, EAI’s people-first service helps clients save energy, conserve water, and extend equipment lifespan.

Learn more about our Cooling Tower Water Treatment Services.

Choosing the Right Chemicals for Lasting Cooling Tower Performance

The efficiency of a cooling tower system depends on more than just its design or operation. The right balance of water treatment chemicals is what ensures stable heat transfer, lower operating costs, and protection against scale, corrosion, and microbial risks. A well-chosen program supports reliability across industries, from power plants and food processing plants to HVAC systems in healthcare and higher education.

Selecting treatment chemicals is not a one-size-fits-all decision. Each facility’s water quality, industry requirements, and performance goals must be carefully considered. With expert guidance, facilities can conserve water, extend equipment lifespan, and achieve the highest efficiency possible.

EAI’s team of certified specialists is ready to design a program tailored to your facility’s needs. Contact EAI today to schedule an onsite analysis and learn how our cooling tower water treatment services can help you save energy and improve system performance.

Frequently Asked Questions (FAQs)

What role do drift eliminators play in cooling towers?

Drift eliminators prevent water droplets from escaping with the air stream. By minimizing drift loss, they reduce chemical waste, conserve water, and improve safety around the tower.

Can treated water from cooling towers be reused?

Yes. Treated water can often be cycled back into the tower to achieve higher cycles of concentration. This reduces make up water demand and helps facilities lower costs.

How does water filter performance affect cooling tower systems?

Strong water filter performance removes other impurities and debris before they circulate. Cleaner tower water protects fill media, reduces fouling, and supports the entire system’s efficient operation.

What challenges occur in cold weather operation?

In cold weather, towers must be monitored closely to prevent freezing of falling water and stress on components. Adjusting flow and heat balance is critical for safe operation.

Are cooling towers only used in industrial plants?

No. While common in petrochemical plants, power plants, and other industrial facilities, they are also typically mounted in HVAC systems for comfort cooling in large buildings.