Water Softeners vs. Water Filters: Which is Better for Industrial Water Efficiency?

When it comes to industrial water treatment, choosing the right equipment can make the difference between smooth operations and costly inefficiencies. One of the most common decisions facility managers face is whether to use a water softener, a water filter, or both. This leads to the broader question: water softener vs filter — which is better for industrial water efficiency?

While both systems serve important but distinct purposes, understanding their roles is critical to improving water quality, protecting infrastructure, and optimizing process performance. Industrial sites often face water hardness issues due to calcium and magnesium minerals, as well as contamination from sediment, organic materials, and dissolved minerals and solids. Left untreated, these problems can lead to scale buildup, corroded plumbing fixtures, equipment downtime, and inconsistent product quality.

This article breaks down how water softeners and filters work, compares their effectiveness in various industrial applications, and explores how advanced systems can work together for maximum impact. If your goal is cleaner water, reduced maintenance, and smarter water usage, knowing when to use a softener vs a filter is a key step in building a more efficient facility.

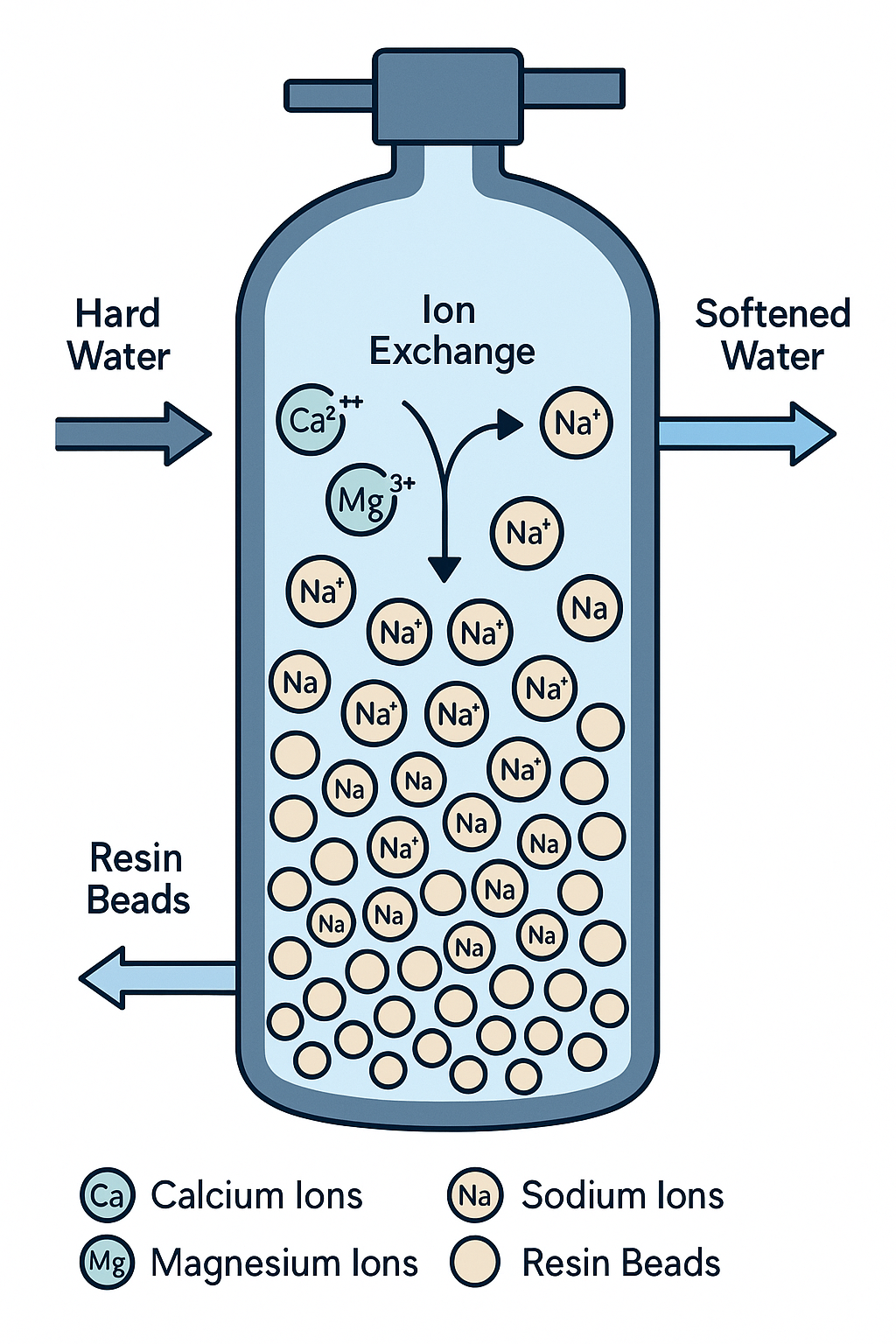

How Water Softeners Work

Water softeners are designed to address one of the most persistent problems in industrial water systems: hardness caused by calcium and magnesium minerals. These hard water minerals can lead to scale buildup in pipes, boilers, cooling towers, and other critical infrastructure. Over time, this buildup reduces heat transfer efficiency, clogs systems, and increases energy consumption and maintenance costs.

The core of a water softener’s operation lies in a process called ion exchange. As hard water passes through the softener tank, it flows over resin beads that are charged with sodium ions. These beads act like magnets, attracting and capturing calcium and magnesium ions from the water and releasing sodium ions in their place. The result is softened water that helps reduce scaling and extend the life of equipment.

Softened water does not remove harmful contaminants or improve taste or odor. Its purpose is to reduce water hardness, which directly impacts industrial efficiency. In facilities that rely on boilers, heat exchangers, or any process sensitive to scale or mineral deposits, a properly maintained softening system can help improve output, protect system longevity, and lower the total cost of ownership.

It’s also worth noting that salt free water softeners, which technically function as conditioners rather than true softeners, do not use ion exchange. These systems attempt to alter the structure of calcium and magnesium minerals so they do not adhere to surfaces, but they may not offer the same scale prevention benefits in high-demand industrial environments.

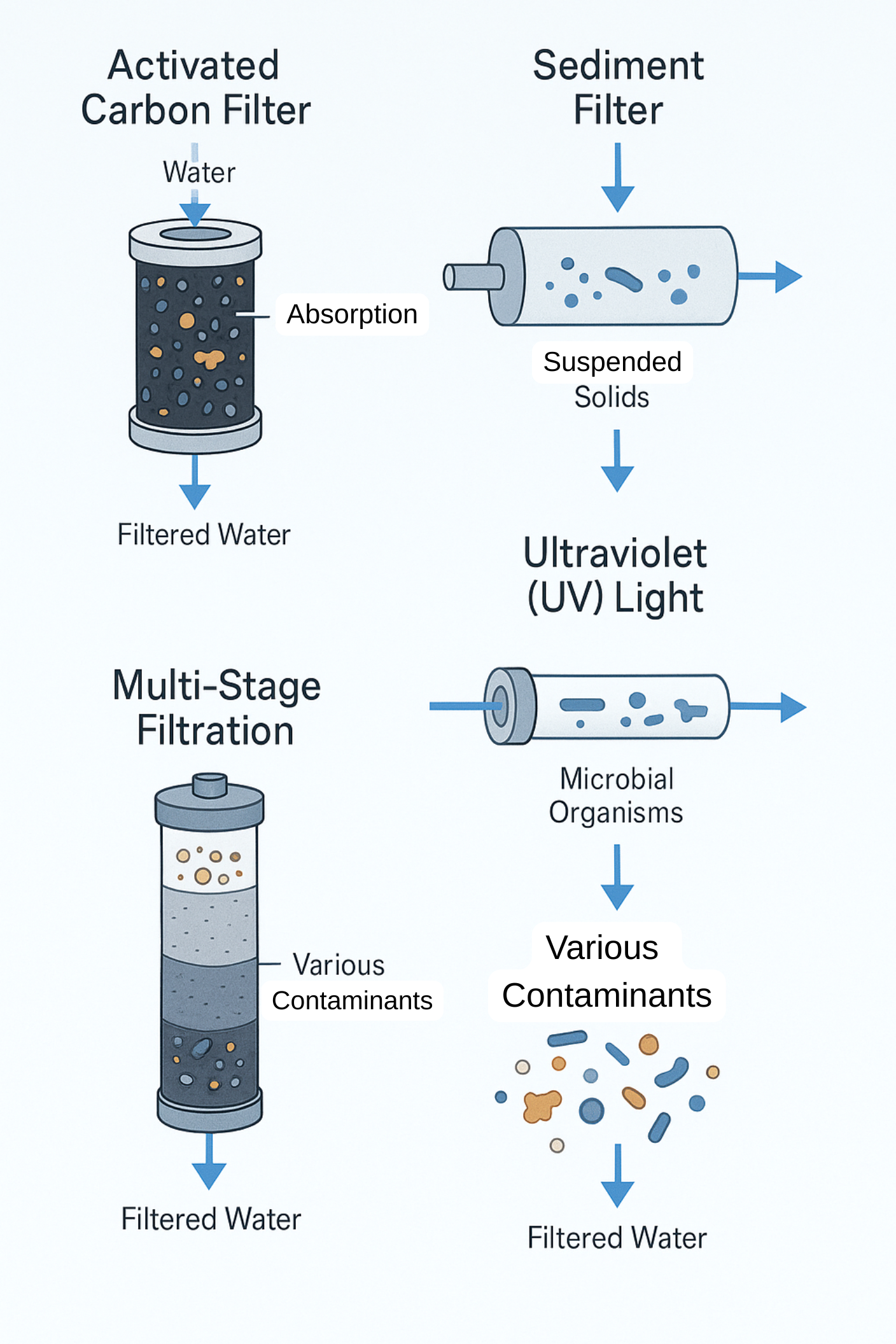

How Water Filters Work

While water softeners focus on removing hard water minerals, water filters are designed to remove contaminants that affect water quality, safety, and process consistency. In industrial settings, filtered water plays a critical role in protecting equipment, meeting regulatory standards, and ensuring product quality across a wide range of applications.

Water filters come in several forms, each targeting different types of contaminants. A common and effective option is the use of activated carbon filters. These work through a process called adsorption, where contaminants adhere to the surface of the carbon media. Activated carbon is particularly effective at removing volatile organic compounds (VOCs), chlorine byproducts, and substances that contribute to unpleasant taste and odor.

Other filtration methods include sediment filters that remove suspended solids, ultraviolet light systems that neutralize microbial organisms, and multi-stage filtration systems that combine several technologies for more comprehensive water treatment. Advanced water filtration systems can also target heavy metals, total dissolved solids, and harmful contaminants that pose health risks or interfere with manufacturing processes.

Unlike softeners, filtration systems do not affect water hardness but instead focus on improving overall water purity. This is especially important for industries such as food and beverage, electronics, and pharmaceuticals, where even trace contaminants in tap water or process water can compromise safety and quality.

Industrial water filters are often integrated into larger treatment systems alongside softeners, especially when dealing with unfiltered water from municipal or well sources. By removing sediment, biological contaminants, and unwanted substances, filters ensure that water used throughout the facility is clean, consistent, and compliant with operational requirements.

Comparing Water Softener vs Filter in Industrial Applications

Choosing between a water softener and a filter is not always a matter of preference. Instead, it depends on the specific water quality challenges an industrial facility is facing. While these two systems serve different purposes, comparing their functions can help identify where each one fits best within your operation.

Water Softeners are ideal for applications where hard water causes mineral buildup on heat transfer surfaces, plumbing fixtures, and process equipment – basically water softening. Facilities that operate boilers, chillers, or any water-based heat exchange system are especially vulnerable to scale buildup from dissolved calcium and magnesium. Softened water helps reduce soap scum, prevents clogged piping, and protects machinery from damage caused by hard minerals.

Water Filters, on the other hand, are essential when water contains unwanted substances like sediment, organic matter, chlorine, or biological contaminants. Filtering improves the safety and clarity of water, helps reduce corrosion, and prevents fouling of sensitive equipment. In industries where clean water is a direct input into the product or a hygiene-critical process—such as food processing or pharmaceutical manufacturing—filtration is non-negotiable.

Here’s how the two systems compare in key areas:

| Feature | Water Softener | Water Filter |

|---|---|---|

| Primary Function | Removes hardness minerals | Removes contaminants |

| Main Target | Calcium and magnesium | Sediment, chlorine, VOCs, microbes |

| Process | Ion exchange | Adsorption, mechanical filtration, UV |

| Ideal Use Case | Preventing scale buildup | Improving water purity and safety |

| Does it remove contaminants? | No | Yes |

| Does it reduce hardness? | Yes | No |

For many industrial systems, using both a water softener and a filter is not only beneficial but necessary. Together, they ensure water is both clean and soft, protecting infrastructure while improving product outcomes and reducing the need for maintenance.

Special Considerations: Salt Free Systems, Reverse Osmosis, and Hybrid Setups

While traditional water softeners and filters are widely used, some facilities explore alternative or supplemental systems depending on their water profile, sustainability goals, and regulatory requirements. These options include salt free systems, reverse osmosis units, and hybrid treatment setups that combine multiple technologies.

Salt Free Water Softeners

Salt free water softeners, often referred to as water conditioners, do not use sodium or resin beads. Instead, they rely on physical or chemical processes to alter the structure of calcium and magnesium minerals so they remain suspended rather than forming scale. These systems can reduce some mineral buildup but are generally less effective in high-demand or high-hardness industrial applications compared to ion exchange systems.

Reverse Osmosis (RO)

Reverse osmosis (RO) is another powerful option, particularly in industries requiring high-purity water. RO systems use a semi permeable membrane to remove dissolved salts, minerals, and a wide range of contaminants from the water supply. This process produces extremely clean water but also generates a waste stream and may require pretreatment to protect the membrane from fouling. RO is especially valuable in applications like electronics manufacturing, pharmaceutical production, or boiler feedwater preparation.

Some facilities benefit from hybrid systems that combine softening, filtration, and RO. These whole house systems—or, in an industrial context, whole facility systems—can be designed to remove sediment, chlorine, calcium, magnesium ions, and dissolved solids all in one integrated process.

How EAI Supports Industrial Water Efficiency With Softeners and Smart Tools

EAI understands that the right water treatment strategy can unlock massive operational savings. For facilities that rely on softened water to protect their boilers, cooling towers, or manufacturing equipment, EAI offers a full line of customizable industrial water softeners as well as industrial reverse osmosis systems. These systems help prevent scale formation, reduce the need for additional chemical treatment, and support water conservation through optimized regeneration cycles and advanced control valves.

But EAI’s commitment to efficiency doesn’t stop with equipment. Our Water Efficiency Program is built around a core goal: achieving a Water Efficiency Score (WES) of six, a benchmark that reflects top-tier performance in cooling tower operations. With tools and expertise designed to lower both water and operating costs, EAI helps clients build resilient and cost-effective water programs.

EAI offers:

- Custom-engineered softeners for flow rates up to 1000+ GPM

- Onsite audits, installation, and remote monitoring capabilities

- Digital flow meter integration and performance tracking

- Optimization software for chemical treatment programs

- Full ROI-based assessments with water and energy savings forecasts

- Rebate research and application support

- Monthly calibration and retrofit services for softener systems

Whether you need a smarter softener or a full-scope efficiency solution, EAI has your six.

Choosing the Right System for Your Industrial Needs

Determining whether a water softener or filter is better for your facility depends on the specific challenges in your water supply. If you’re dealing with hard minerals like calcium and magnesium that lead to mineral deposits, soap scum, and scale buildup, a softener is likely the right choice. If your concern is contaminated water, unpleasant taste, or protecting your facility from harmful health risks, a filtration system may be more effective.

In many cases, using both a water softener and filter provides the most comprehensive protection. Together, they can reduce operational downtime, protect equipment, and improve both water quality and your team’s comfort—from smoother operations to softer skin and cleaner dishes in wash-down areas.

Ultimately, the best solution is one that aligns with your facility’s water conditions, system design, and performance goals. Working with a knowledgeable water treatment provider ensures your setup is optimized for long-term results.

Learn how EAI Water’s integrated softening and filtration solutions can optimize your industrial water efficiency. Contact us today!

Frequently Asked Questions (FAQs)

Can I use both a water softener and a filter in the same system?

Yes, using both a water softener and a water filter allows you to address hard minerals and unwanted contaminants simultaneously. This approach is especially helpful in industrial settings where tap water quality varies and process performance is critical.

What’s the difference between a whole house filter and a water softener?

A whole house filter removes unwanted substances like sediment, chlorine, and organic matter from all water entering a building. A water softener, on the other hand, is designed to remove calcium and magnesium ions that cause hardness. Each serves a different purpose but can be used together for comprehensive treatment.

Can unfiltered water pose risks to equipment or health?

Yes. Unfiltered water can carry health risks, such as exposure to heavy metals or microbial contaminants. It may also lead to mineral buildup inside pipes and machinery, causing efficiency losses or damage.

Why does my facility’s water have an unpleasant taste or odor?

This is often due to dissolved calcium, volatile organic compounds, or chlorine byproducts. A high-performance filtration system with activated carbon can significantly improve taste and deliver great tasting water across your operations.