Preventing Legionella in Cooling Towers

At EAI, we are deeply committed to being your total water solutions provider. As experts in comprehensive water quality strategies, we aim to educate customers on critical water treatment issues to minimize risk while also providing customized solutions to save water and money. Guided by our core values of integrity, accountability, continuous improvement, and being good stewards, we strive to approach every customer situation with care and attentiveness. Pathogen control and prevention is one area that is often overlooked in cooling towers, but always an important consideration in our total water treatment approach.

Legionella is a potentially dangerous bacterium that can amplify and spread through building water systems, most notably cooling towers. This risk has been well-known since the infamous 1976 outbreak of Legionnaires’ disease in Philadelphia, which was traced back to cooling towers at the Bellevue-Stratford Hotel that was hosting a Legionnaires convention. Over 200 people contracted the severe form of pneumonia, and over 30 individuals perished. This alarming event put the spotlight on the risks posed by cooling towers and water systems to public health.

Though we have learned a great deal about Legionella risk management since 1976, it remains an ever-present concern today for facility managers and building operators. Cooling towers can provide ideal conditions for the growth and spread of Legionella through water droplets. If not properly controlled, this can put building occupants at risk of contracting Legionellosis or Pontiac Fever.

This article will provide current best practices for Legionella prevention and control in cooling towers.

What is Legionella, and why is it a concern in cooling towers?

Legionella refers to a genus of bacteria that encompasses over 60 species. The species that most commonly causes illness in humans is Legionella pneumophila. This bacterium can lead to a severe form of pneumonia known as Legionnaires’ disease when inhaled in contaminated water droplets. A milder infection called Pontiac Fever may also occur, causing flu-like symptoms.

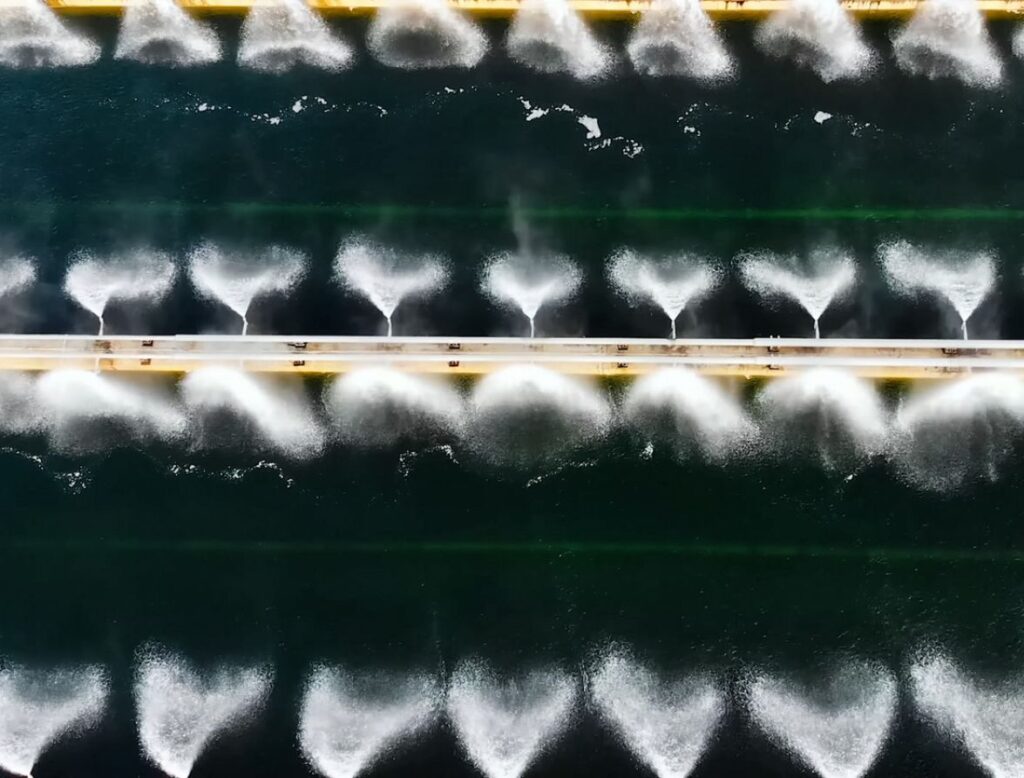

Legionella bacteria occur naturally in freshwater environments but can grow and spread in the warm, stagnant conditions found in building water systems. Cooling towers are particularly susceptible as they can enable Legionella amplification due to the optimal temperature range for growth, the right pH levels, sediment that collects at basin floors, and constant exposure to new inoculations from makeup water.

The bacteria may enter the cooling tower system through incoming makeup water, which contains low background levels of Legionella even when properly treated. The organisms can also find their way in by parasitically infecting free-living protozoa and aquatic biofilms already present in the system. They can also be carried into the cooling tower through airborne dust particles.

Once Legionella colonizes a cooling tower, the population can quickly multiply under the right conditions. However, it is important to note that Legionella is not introduced through improper external contamination in most cases. Rather, amplification occurs due to natural background levels that are ever-present in our water sources. Maintaining biocide treatment programs and proper system maintenance helps control this occurring.

How does Legionella bacteria proliferate in cooling towers?

“Cooling towers are particularly susceptible because the temperature range they typically operate at is perfect for Legionella,” notes Ryan Vargas, EAI’s Director of Business Development in Northern California.

The warm and nutrient-rich water kept within cooling towers, maintained around 77-108°F for optimal thermal transfer, happens to be the perfect breeding range for Legionella. These warm temperatures encourage rapid cell replication. The pH levels in cooling towers are also kept slightly alkaline, which favors growth.

Additionally, open-recirculating cooling towers expose the reservoir to outside sources of Legionella on a constant basis from makeup water and the surrounding air. On the other hand, closed-loop systems have contained water used for heat transfer and aren’t susceptible in the same way. With the air exposure, open cooling towers provide all the conditions Legionella needs to thrive while closed systems pose far less risk.

The warm, alkalized water source, constant exposure to contaminated aerosols, and a never-ending supply of nutrients all make cooling towers the ideal rear-guard encampments for these microscopic organic invaders to run amok.

What are the best practices for preventing Legionella growth in cooling towers?

Best practices include regular maintenance and cleaning, implementing a robust biocide treatment program, and conducting routine testing to monitor bacterial levels. These measures help control biofilm buildup, sediment accumulation, and microbial populations. Proper cooling tower maintenance and water treatment form the frontline defense against Legionella overgrowth. By following industry best practices, facility managers can greatly reduce the risks involved.

Regular Maintenance and Cleaning

Performing periodic power cleanings of tower basins, heat exchange media, and other wetted components is critical for controlling biofilm buildup and sediment accumulation. Expert guidance recommends cleanings at least twice per year, while towers in dusty environments or high loading may require more frequent servicing. “Cooling towers are constantly sucking things in. It’s a giant vacuum on one end, and it’s a giant blower on the other,” added Vargas. These neglected areas can shelter Legionella colonies and provide prime real estate for robust growth.

Water Treatment Programs

In addition to physical cleaning, well-managed biocide programs provide chemical disinfection of process water and wet tower surfaces. Typically an oxidizing biocide (e.g. sodium hypochlorite, bromine) is paired with a non-oxidizing biocide (e.g. isothiazolin, glutaraldehyde) for treatment. When maintained at proper concentrations, contact times, and frequencies, these chemical regimes exert control on microbial populations.

Routine testing using heterotrophic plate counts and periodic Legionella assays should be conducted to gauge program efficacy. Any sudden increases measured should prompt corrective action, including shock disinfection procedures if necessary. Following prescribed preventative measures can hold amplification risks to a minimum.

By keeping towers and basins clean, biocide levels adequate, and regularly verifying program effectiveness, facility managers can best avoid finding themselves blinded to lurking hazards. Implementing these industry standards pays major dividends through reduced equipment damage, energy savings, and protection of human health.

The Role of Water Management Plans

Water management plans provide a codified and systematic approach for facilities to control Legionella risks. ASHRAE published Standard 188 in 2021, which outlines minimum recommendations for these plans including risk assessments, routine verification, and corrective response procedures when action thresholds are exceeded.

Effective WMPs start by assembling a water management team with cross-functional representation. Together they perform a facility risk analysis on each equipment system to tailor the management plan appropriately. This covers components like the cooling towers, domestic water loops, humidifiers, decorative fountains, and so on. The team then decides on sampling frequencies, monitoring methods, acceptable microbiological limits, and specific disinfection protocols to enact when Legionella is detected at concerning levels.

The water management team implements the WMP across the building’s water systems through training maintenance staff, posting quick reference guides, and scheduling annual reviews. Routine verification testing takes place for both general heterotrophic bacteria and periodic Legionella screening specifically. Audit checks confirm that all processes are being properly executed. Any Legionella detections above the allowable limit trigger the prescriptive response outlined in the WMP.

By institutionalizing these practices into a water management plan, facilities take control of Legionella hazards through expertise-driven diligence. Careful application of the core principles from ASHRAE 188 enables sustainable risk reduction. The EAI team highly recommends having a WMP in place prior to starting any testing at the site or facility.

How should facilities respond if Legionella is detected in their cooling system?

Even facilities with excellent water management plans in place may still encounter an unexpected positive test result. In these situations, responding swiftly and correctly is critical.

Initial actions center on confirming the result and enacting disinfection procedures. The first step should be to send a follow-up sample to a CDC-certified laboratory for verification and speciation of the bacteria detected. Concurrently, supplemental disinfection of the affected system using high levels of oxidizing and non-oxidizing biocides should commence. If Legionella is shown to be present at dangerous levels, a complete system shutdown and intensive disinfection process may be needed.

With health risks in the balance, obtaining expert consultation is advisable when facing a positive Legionella test. Water treatment specialists assist in developing the tactical response plan, advising on additional decontamination steps, and adjusting the water management program to mitigate recurrence. Facilities should use these incidents to re-examine risk points and upgrade prevention strategies.

Upon receiving a positive Legionella result, facilities should spring into action by validating the outcome, thoroughly disinfecting the system, confirming eradication through further testing, and consulting water treatment experts on permanent corrective measures to prevent future exposure threats.

Common Misconceptions About Legionella

Perhaps the most dangerous and common misconception facility managers have about Legionella is that any detectable presence indicates imminent peril. Trace detections may occur randomly even in well-managed building water systems. Facility experts set limits in their water management plans above which action is required to bring populations back into check. So a low-level positive does not necessarily signify a lapse in control or risky condition.

Problems arise when amplification has been allowed to progress too far, enabling exponential growth. If testing reveals concentrations or particular species known for higher virulence above concerning benchmarks, then the facility would escalate disinfection efforts accordingly. So while any Legionella detected warrants attention, the risk level lies in the magnitude.

The ever-present nature of Legionella in our environment means some vigilance will always remain necessary. Facility managers carry an important responsibility for protecting the health and safety of occupants. By staying informed on industry guidelines and leaning on the expertise of water treatment specialists whenever questions arise, building operators can keep amplification risks low and cooling towers from becoming sources of disease. If you are concerned about preventing Legionella in your cooling system, contact us and speak with an expert today.

As your dedicated total water solutions partner, EAI is here to both inform and serve when it comes to cooling tower water treatment. Our Total Water approach uses a combination of specialized chemical, softening, filtration, and disinfectant technologies tailored to your unique operational needs. We aim to simplify water for our customers through expertise-driven service while upholding accountability, integrity, and environmental stewardship. Please reach out if we can assist with your facility’s water treatment requirements or provide guidance on amplification risk prevention.