A Guide to the Industrial Wastewater Treatment Process

Almost every industrial activity generates wastewater containing a mix of suspended solids, organic pollutants, and toxic materials that can’t be discharged without proper treatment. The consequences of skipping or mishandling the wastewater treatment and wastewater discharge process can include regulatory violations, environmental harm, and long-term operational risks.

With a structured approach using physical, chemical treatment, and biological methods, industrial facilities can transform contaminated water into safe discharge or even reuse it internally through the right industrial wastewater treatment process.

In this guide, we’ll break down the most common treatment stages, contaminants to address, and technologies used in modern facilities. We’ll also discuss how EAI supports industrial clients with custom-designed solutions that meet compliance goals, reduce operational costs, and support water reuse.

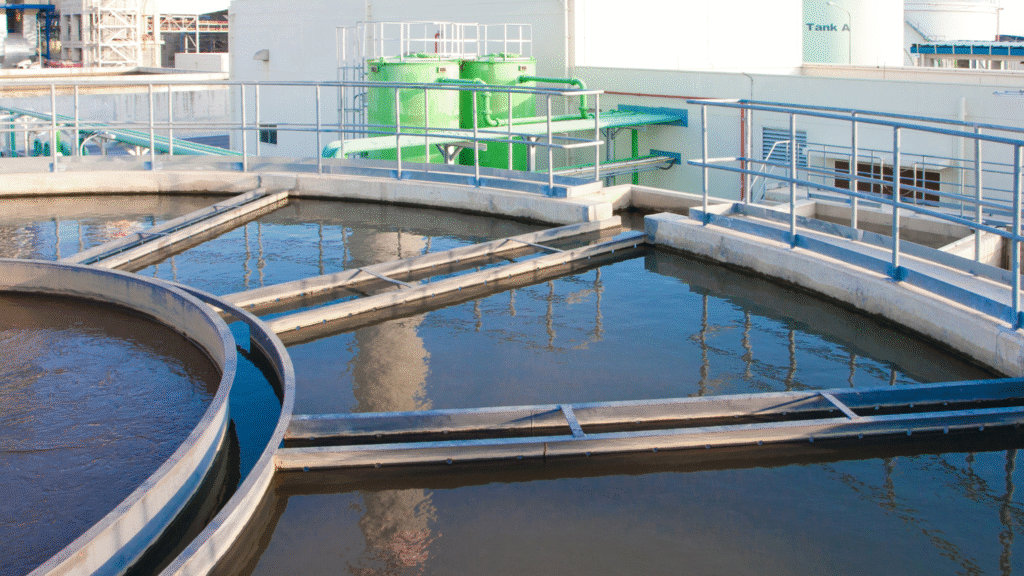

What Is the Industrial Wastewater Treatment Process?

The industrial wastewater treatment process involves steps and technologies used to remove harmful contaminants from wastewater generated during manufacturing or commercial operations. These processes make it possible for water to be discharged safely into the environment, a municipal sewer system, or reused within the facility.

Unlike municipal wastewater, which has relatively consistent composition, treating wastewater industrially varies widely based on the process that produced it. A food and beverage facility may deal with high organic materials and grease, while a plating shop may face toxic metals, acids, or oil-laden streams. That variability makes it critical to assess the wastewater composition before selecting treatment methods.

Industrial facilities may generate multiple wastewater streams, including:

- Cooling tower blowdown

- Equipment wash water

- Chemical processing rinse water

- Boiler blowdown or condensate

- Effluent from mixing or blending operations

Whether the goal is to meet discharge permits, reduce environmental impact, or support internal reuse, each treatment program must be engineered to match the industrial process, volume, and regulatory requirements involved.

Common Contaminants in Industrial Wastewater

The complexity of industrial wastewater lies in its diverse and often unpredictable mix of contaminants. These substances not only pose a threat to the environment but can also damage equipment, increase treatment costs, and lead to noncompliance with discharge regulations.

Here are the most common pollutants found in wastewater streams across various industries:

1. Suspended Solids and Sediment

These include sand, silt, metal shavings, and other solid particles that remain undissolved in water. If not removed early through filtration systems or sedimentation, they can clog piping, damage pumps, and interfere with downstream treatment processes.

2. Organic Materials

Many facilities, especially those involved in processing food, pharmaceuticals, or paper, produce high levels of biodegradable organic material. These materials demand biological treatment to prevent oxygen depletion in receiving water bodies.

3. Toxic Compounds

Industrial operations that involve solvents, paints, pesticides, or petroleum often produce toxic chemicals such as phenols, hydrocarbons, and chlorinated compounds. These must be treated carefully due to their persistence and risk to human and environmental health.

4. Heavy Metals

Common in mining, electronics, and metal plating industries, toxic metals like lead, mercury, cadmium, and chromium can accumulate in sludge or pass into the environment if not properly removed.

5. Oils, Grease, and Fats

Fats, oils, and grease (FOG) are prevalent in food manufacturing and equipment cleaning processes. They require grease removal steps early in treatment to prevent fouling of biological systems and membrane filtration units.

6. Dissolved Salts and Nutrients

Excessive salts, phosphates, and nitrates can trigger harmful algal blooms and damage ecosystems. Advanced treatment or reverse osmosis may be necessary to manage these compounds, especially in zero-liquid-discharge or reuse applications.

Stages of the Treatment Process

Effective industrial wastewater treatment is typically divided into three main stages: primary, secondary, and tertiary treatment. Each stage targets a different class of contaminants and progressively improves water quality for discharge or reuse.

A. Primary Treatment: Removing Solids and Oils

The first step in treating industrial wastewater is separating out large and easily removable materials. This is often done using mechanical systems designed to handle heavy flows and debris-laden influent.

Key methods include:

- Screening and grates: Remove debris like rags, plastics, or packaging waste.

- Grit chambers: Settle out heavier solid particles like sand or silt.

- Sedimentation tanks: Allow gravity to separate suspended solids and waste sludge.

- Grease removal systems: Float oils and fats to the surface for skimming.

At this stage, the goal is not full purification, but to reduce the physical load on downstream systems. Removing suspended solids and grease early helps prevent clogging and improves efficiency in biological and chemical stages.

B. Secondary Treatment: Biological Breakdown of Organic Matter

Once large debris and sediments are removed, the next step focuses on removing organic matter through biological treatment. This involves cultivating microorganisms that consume dissolved contaminants as food.

Common biological treatment systems include:

- Activated Sludge Process:

In this widely used method, wastewater enters an aeration tank where it is mixed with air and activated sludge (a microbial-rich slurry). The bacteria break down organic compounds, converting them into carbon dioxide, water, and more microbial biomass. The water then passes to a clarifier to separate the new sludge from treated water. - Trickling Filters:

Water flows over a bed of media coated in bacteria. As the wastewater moves through the filter, the biofilm consumes organic pollutants. - Sequencing Batch Reactors (SBRs):

These are time-based systems that perform aeration, settling, and sludge removal in a single tank.

These biological processes are critical for facilities with high levels of organic materials such as food, beverage, or pharmaceutical plants. They help reduce biochemical oxygen demand (BOD) and stabilize water chemistry before advanced polishing.

C. Tertiary Treatment: Polishing and Advanced Removal

In facilities that require high-purity discharge or water reuse, tertiary treatment addresses very fine solids, nutrients, salts, and remaining pathogens.

Common tertiary methods include:

- Membrane Filtration (e.g., reverse osmosis, ultrafiltration, nanofiltration)

- Chemical Precipitation for phosphates and metals

- UV disinfection or chlorination to kill microorganisms

- Carbon filtration to remove odors, color, and trace organic chemicals

This stage is where industrial wastewater treatment technologies are most tailored to a facility’s reuse goals. Whether water is being discharged into the environment, reused for non-potable applications, or recycled back into the industrial process.

Key Industrial Wastewater Treatment Methods

Each industrial wastewater treatment process is shaped by the nature of the contaminants, regulatory targets, and the facility’s operational goals. While the treatment stages provide a broad structure, the actual technologies deployed can vary widely. Below are some of the most common and effective industrial wastewater treatment methods used across different sectors.

1. Ion Exchange

This method is used to remove specific dissolved ions (i.e. heavy metals, calcium, magnesium, and nitrates) by exchanging them with harmless ions held in a resin bed. It’s especially effective for polishing treated water or conditioning it for reuse.

- Best for: Removing dissolved solids and specific contaminants in low concentrations

- Common applications: Electronics, pharmaceutical, and chemical manufacturing

2. Chemical Treatment

Chemical reactions like neutralization, coagulation, and oxidation play a major role in removing toxic compounds and destabilizing organic matter or emulsified oils.

- Neutralization balances acidic or alkaline pH

- Coagulants help bind very fine particles into larger clumps for removal

- Oxidation breaks down complex organic molecules into less harmful substances

Chemical dosing systems are often automated and tightly monitored to maintain treatment efficiency while avoiding overtreatment or hazardous by-products.

3. Membrane Filtration

Membrane-based systems such as reverse osmosis (RO), ultrafiltration (UF), and nanofiltration (NF) are increasingly used in tertiary treatment. These systems use pressure to push water through selective membranes, removing:

- Very fine solids

- Salts and minerals

- Microorganisms

- Organic and inorganic pollutants

They are essential in zero liquid discharge applications or where water needs to be reused in sensitive operations.

4. Dewatering Methods

Handling waste sludge is a critical part of any wastewater process. Dewatering techniques reduce its volume and weight, making disposal more cost-effective.

Common options include:

- Centrifuges: Use rotational force to separate water from solids

- Belt filter presses: Apply mechanical pressure through belts to squeeze out water

- Geotextile bags: Used for passive, gravity-driven dewatering of sludge volume in remote or low-volume facilities

5. Automated Monitoring and Control Systems

Modern treatment systems increasingly rely on automation to ensure consistency, reduce labor, and respond to water quality fluctuations in real time. Sensors track pH, turbidity, chemical dose, and flow rates to keep the process efficient and compliant.

Each of these methods plays a role in customizing the treatment process to a facility’s unique wastewater composition, treatment goals, and available footprint. The most effective systems combine multiple technologies into a cohesive, adaptive solution.

EAI’s Approach to Industrial Wastewater Treatment

At EAI, we understand that no two wastewater streams are the same. That’s why our treatment programs are custom-built from the ground up, blending field-tested engineering with application-specific chemistry and modern automation. Our solutions help clients meet regulatory standards while improving resource efficiency and system reliability.

Custom System Design

We start by evaluating each facility’s wastewater composition, including contaminants, discharge requirements, and opportunities for water reuse. Whether the waste stream comes from processing food, pharmaceutical manufacturing, or cooling tower blowdown, we develop a targeted strategy using the most effective treatment technologies available.

Our wastewater services include:

- Tailored chemical and mechanical treatment systems

- Zero liquid discharge (ZLD) design

- Environmental compliance management

- Long-term planning for water reuse and recycling initiatives

Industrial Reverse Osmosis Systems

For facilities requiring high-purity effluent or advanced tertiary treatment, EAI designs and maintains robust reverse osmosis (RO) systems. These systems are built to handle demanding industrial loads and include:

- Pretreatment options (multimedia, carbon, or cartridge filters)

- Energy-efficient membranes

- CIP skids and membrane cleaning service

- Automated performance monitoring and membrane life optimization

Our industrial RO systemsare engineered for reliability, minimal downtime, and seamless integration into your existing operations. Systems are skid-mounted, containerized, and available in capacities ranging from 15,000 to over 1 million gallons per day.

On-Site Disinfection and Chlorine Generation

For advanced disinfection and pathogen control, EAI offers on-site chlorine dioxide generation systems using our proprietary electrochemical architecture. These systems allow for high-purity chlorine dioxide production without acid use, reducing by-product formation and corrosion risks.

These generators support:

- Secondary disinfection in water reuse applications

- Thermal storage sanitation

- Compliance with microbial and Legionella control standards

Whether your goal is regulatory compliance, operational efficiency, or environmental stewardship, EAI provides the technical depth and ongoing support to optimize your entire industrial waste water treatment process from start to finish.

Meeting Environmental Regulations and Standards

One of the most important functions of any industrial wastewater treatment process is ensuring that treated water meets the discharge limits set by federal regulations, state agencies, and local utilities. Failure to comply can result in steep fines, shutdown orders, or long-term reputational damage.

Facilities discharging to a local sewer or publicly owned treatment works (POTW) must often pre-treat their wastewater to remove substances that could harm municipal systems or violate permit conditions. Others that discharge directly into water bodies face even more stringent requirements under the Clean Water Act and National Pollutant Discharge Elimination System (NPDES).

Proper industrial wastewater management helps:

- Prevent contamination of lakes, rivers, and groundwater

- Minimize exposure to toxic compounds and organic pollutants

- Ensure alignment with industry-specific discharge permits

- Support corporate sustainability and environmental goals

By applying the right treatment methods and validating system performance through regular testing and reporting, facilities can meet compliance targets while protecting the surrounding environment.

Ready to Optimize Your Wastewater Process?

EAI’s team of chemists, engineers, and field technicians specialize in developing high-performance solutions for complex industrial challenges.

Contact us today to schedule a system evaluation and take the next step toward more reliable, cost-effective, and environmentally responsible solution in treating wastewater.