Healthcare Secondary Disinfection: Chlorine Dioxide vs Monochloramines

Water safety plays a direct role in preventing healthcare-associated infections. From tap water to misting devices, any part of a building’s drinking water treatment system can become a source of microbial contamination if not properly treated. That’s why secondary disinfection has become a key focus in hospitals and clinics, especially in facilities with complex plumbing, high patient risk, or a history of pathogens like Legionella in drinking water.

Municipal water treatment plants typically provide primary disinfection, but by the time water travels through aging pipes and low-use fixtures, its microbial profile and related drinking water quality can change. To maintain safe conditions, many hospitals turn to secondary disinfection: a targeted approach that treats drinking water inside the building, not just at the original source. Two of the most widely used solutions are chlorine dioxide and monochloramines, each with its own strengths, risks, and ideal applications.

With almost 40 years of experience designing disinfection systems for water purification processes, EAI helps facilities implement tailored solutions that protect patient health. In this article, we’ll break down the differences between chlorine dioxide and monochloramines, and help you understand when each is best suited for protecting patients, systems, and staff.

What is Secondary Disinfection?

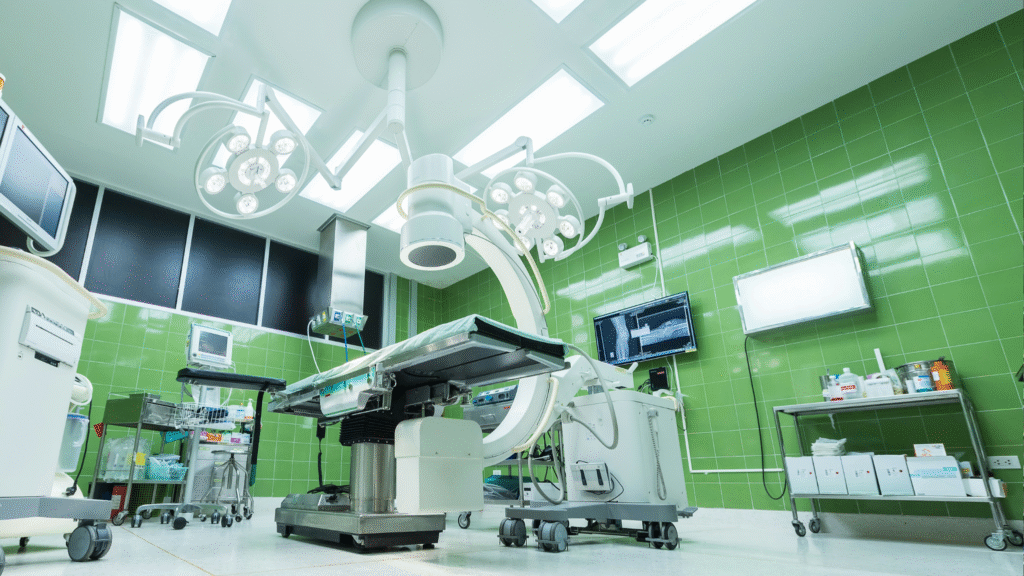

Secondary disinfection in a healthcare setting refers to the continuous treatment of a facility’s potable water after it enters the building, serving as a safeguard beyond municipal water treatment plant-level disinfection. This internal treatment layer is especially important in hospitals and long-term care facilities, where immunocompromised patients face greater risks from even low levels of microbial activity.

Unlike disinfection and sterilization procedures used for instruments like endoscopes or medical devices, secondary disinfection is applied to the water supply itself—helping to disinfect drinking water and target bacteria and biofilms that grow in piping, faucets, or dead legs. These water treatment systems help remove dissolved particles and control microbial regrowth throughout domestic hot and cold loops, often using chemical disinfectants like chlorine dioxide or monochloramines.

Healthcare plumbing is particularly vulnerable due to warm temperatures, low-use fixtures, and system complexity. Without secondary disinfection, pathogens such as Legionella, Pseudomonas, and other waterborne pathogens can persist and spread through mists, splashes, or direct patient contact. A well-designed water treatment process helps ensure consistent water quality and public health compliance from the point of entry to point of use.

Chlorine Dioxide in Healthcare Water Systems

Chlorine dioxide is a powerful oxidizing agent widely used in healthcare secondary disinfection programs for its ability to inactivate a broad range of pathogens, including Legionella, Pseudomonas, and spore-forming bacteria. Generated on-site from sodium chlorite, chlorine dioxide behaves as a dissolved gas, maintaining stability across a wide pH range while avoiding the formation of toxic substances like THMs.

Unlike chlorine gas, chlorine dioxide gas is highly selective and effective at killing bacteria and disrupting biofilms that form inside piping, showerheads, and fixtures. This helps maintain clean water and suppress microbial contamination at the source.

Operationally, on-site generation minimizes the transport of hazardous substances and supports precise dosing. These water treatment systems are compatible with HVAC loops, low-flow outlets, and water treatment systems in clinical environments—making them an ideal option for disinfection in sensitive healthcare settings.

To ensure regulatory compliance, chlorine dioxide systems must be managed to meet Environmental Protection Agency (EPA) limits for byproducts such as chlorite (maximum contaminant level of 1.0 mg/L) and chlorate (a health advisory limit of 0.7 mg/L).

Monochloramines as a Secondary Disinfection Option

Monochloramines, created by combining chlorine with ammonia, are commonly used in large public water treatment plants for their long-lasting stability in distribution systems. They’re valued for their persistence, especially where disinfectant must travel long distances to reach remote outlets.

However, in healthcare settings, their performance is more limited. Monochloramines are less effective at disinfecting water in complex piping or areas prone to biofilm buildup. Their reduced oxidative strength means they may not fully inactivate pathogenic bacteria in high-risk zones, particularly where critical devices or normally sterile tissue could be exposed. On the other hand, monochloramines perform comparatively well in hot water systems, where their persistence reduces the risk of disinfection byproduct generation.

Proper application requires careful monitoring of the chlorine-to-ammonia ratio to prevent nitrification. System pH and temperature can also affect outcomes. While monochloramines can be effective in maintaining disinfection residuals, they may not be the best fit for facilities with stagnant water, aging infrastructure, or heightened patient vulnerability.

Key Considerations for Healthcare Facilities

Choosing the right secondary disinfection method involves aligning with the unique infrastructure, usage patterns, and infection risk profile of the facility. Below are key factors infection control professionals and operations teams should evaluate:

System Conditions and Risk Factors:

- Aging infrastructure and low-flow zones may trap contaminants and foster biofilm.

- A history of waterborne pathogens like Legionella signals the need for more aggressive watre treatment and disinfection.

- Facilities with heat-sensitive endoscopes or critical devices need non-corrosive disinfectants compatible with complex water treatment systems.

Operational and Safety Considerations:

- Chlorine dioxide is favored for its ability to penetrate biofilms, function across pH ranges, and disrupt dissolved particles that contribute to microbial growth.

- Monochloramines offer stability over long distances and in hot water loops but may underperform in dynamic, high-risk water networks.

Staff Training and Oversight:

- Successful systems depend on properly trained staff and ongoing annual competency testing.

- Disinfection plans should be reviewed regularly during infection control rounds to ensure safety and efficiency.

Facilities should also meet Environmental Protection Agency (EPA) guidelines and monitor for potential harmful effects from residuals or dosing errors.

Comparing Chlorine Dioxide and Monochloramines for Healthcare Use

When it comes to healthcare secondary disinfection, both chlorine dioxide and monochloramines are widely used, but their effectiveness and suitability vary depending on the system’s design, microbial risks, and facility goals.

Chlorine Dioxide: Precision and Pathogen Control

Chlorine dioxide is known for its highly effective action against a wide spectrum of pathogens, including Legionella, Pseudomonas, and even spore-forming bacteria. It excels in disrupting biofilms and maintains performance across a wide pH range. Its on-site generation from sodium chlorite allows for greater control and reduces the need for transporting hazardous substances. For hospitals with aging plumbing or high microbial risk, chlorine dioxide is often preferred for its broad efficacy and minimal by product formation.

Monochloramines: Stability Over Distance

Monochloramines, on the other hand, offer residual stability that makes them valuable in large or extended distribution systems. They are often used in public water treatment facilities because they degrade more slowly and can maintain disinfectant presence over longer pipe runs. They are also highly effective and persistent in hot water loops. In some high-risk healthcare environments, however, their reduced oxidation potential and limited biofilm penetration can potentially leave gaps in protection – particularly around critical devices or normally sterile tissue.

Decision Factors for Healthcare Facilities

The right choice depends on:

- The age and complexity of the plumbing system

- Quality parameters (pH, TDS, iron levels, temperature)

- The types of pathogens historically present in the system

- Regulatory requirements and infection control goals

- Compatibility with other disinfection methods like UV light or reverse osmosis

Both disinfectants can play a role in broader water treatment systems, but their suitability for healthcare depends on how well they align with operational needs and risk tolerance.

To explore a deeper technical comparison, including generator design and operational tradeoffs, check out our blog about Chlorine Dioxide vs. Monochloramine Generators: A Comparative Overview

EAI’s Role in Designing Safe Secondary Disinfection Programs

At EAI, we design and implement water treatment programs that meet the rigorous demands of healthcare environments. With more than 35 years of experience supporting healthcare facilities, we understand the systems, regulations, and performance goals that drive successful outcomes.

Each program starts with a full facility assessment—including water testing, risk analysis, and equipment inspection. Based on findings, we design customized plans that may include chlorine dioxide generation, monochloramines, UV light disinfection, or reverse osmosis systems to support high-purity applications. Whether addressing HVAC loops, potable water systems, or cooling towers, our goal is always the same: to deliver treated water that’s safe, compliant, and built around your facility and patients’ needs.

We support our clients with in-house chemists, engineers, and field technicians, ensuring you have a single source for managing industrial water treatment and compliance. For a closer look at how we support hospitals, pharmaceutical facilities, and R&D labs, visit EAI’s Water Treatment for Healthcare.

Water Safety for Human Health

The right secondary disinfection plan protects more than infrastructure, it protects lives. Partner with EAI to build a solution tailored to your healthcare facility.

Connect with us to learn more.

Frequently Asked Questions (FAQs)

1. What makes chlorine dioxide safer than chlorine in healthcare applications?

While both are used for disinfection, chlorine dioxide is typically generated on-site in controlled amounts and doesn’t produce harmful byproducts like chlorine gas or ozone. It also avoids the formation of by product compounds such as THMs, making it safer for use in systems that serve public use and patient environments.

2. How does water treatment for healthcare differ from other water treatment plants?

Water treatment plants serving the general public focus on mass water purification and filtration at scale. In contrast, healthcare-specific water treatment systems are designed to protect vulnerable populations and safely return water that meets strict quality standards. This often includes chemical dosing, temperature control, and system monitoring specific to the needs of healthcare facilities.

3. What are the risks of using high doses of disinfectant chemicals in hospital water treatment processes?

Using high doses of chemicals such as chlorine or monochloramines can trigger the release of hazardous substances and lead to harmful effects like pipe corrosion, unpleasant water taste, and chemical byproducts. In sensitive healthcare environments, improper dosing may introduce health risks to patients, staff, or even compromise red blood cells if residual levels aren’t tightly controlled. That’s why expert oversight is critical. EAI helps healthcare facilities design precise water treatment programs that optimize disinfection performance while minimizing chemical exposure.

4. Are healthcare facilities monitored by the EPA?

Yes. The Environmental Protection Agency sets regulatory standards for treated water, especially when facilities receive water from public water treatment plants. Healthcare systems must also meet additional infection control criteria related to disease transmission, chemical disinfectants, and residual levels.

5. How do hospitals ensure that industrial water systems don’t contaminate patient-use water?

Hospitals use separation between industrial water supply (e.g., cooling towers, autoclaves) and drinking water lines, along with backflow prevention and disinfection barriers. Proper design and treatment methods ensure that wastewater treatment zones and solids separation processes don’t affect water safe zones meant for human contact or consumption.

6. Do hospitals use advanced water treatment technologies beyond chemical disinfection?

Yes. Many healthcare facilities use a multi-barrier approach that includes technologies like UV light disinfection and reverse osmosis to further enhance water quality. UV light is often used to inactivate microorganisms without adding chemicals, while reverse osmosis removes dissolved salts, organic compounds, and other fine particulates that chemical disinfectants alone may not address.