The Benefits of Electrochemical Generation of Chlorine Gas vs. On-Site Chlorine Cylinder Storage

Chlorine gas is a widely used disinfectant in various industries, particularly in water treatment, as a chlorate free solution for food and beverage manufacturing. Traditionally, chlorine gas has been stored on-site in large cylinders, ready to be used as needed, but with understandable concern related to the potential impacts of storing chlorine gas. However, recent advancements in electrochemical generation technology have introduced a safer, more efficient alternative: generating chlorine gas on-demand through electrochemical systems. This method offers several significant advantages over traditional chlorine tank storage, making it an increasingly popular choice for facilities looking to enhance safety, efficiency, and environmental sustainability.

Enhanced Safety and Reduced Risk

One of the most compelling reasons to choose electrochemical generation over on-site chlorine tank storage is the substantial improvement in safety. Chlorine gas, while highly effective as a disinfectant, is also hazardous. Storing large quantities of chlorine on-site poses significant risks, including the potential for leaks, spills, and exposure to personnel and other business residents/attendees.

- On-Demand Production: Electrochemical generation systems produce chlorine gas as needed, eliminating the need to store large quantities of hazardous chemicals. This on-demand production drastically reduces the risk of accidental releases and the associated health and safety concerns.

- Minimized Chemical Handling: With electrochemical systems, there is no need to transport or handle large chlorine cylinders or tanks, further reducing the risk of accidents and exposure to dangerous substances.

Operational Efficiency and Cost Savings

While the initial capital investment for an electrochemical generation system may be higher than for traditional chlorine storage cylinders or tanks, the long-term operational benefits often outweigh these upfront costs. Electrochemical generation systems are designed to be highly efficient, offering several advantages that translate into cost savings over time.

- Lower Operating Costs: By generating chlorine gas on-site, facilities can avoid the costs associated with purchasing, transporting, and storing large quantities of chlorine gas. Additionally, the precise control offered by electrochemical systems ensures that only the necessary amount of chlorine gas is produced, reducing waste and optimizing chemical use.

- Reduced Maintenance: Chlorine cylinders require regular maintenance to ensure safety and compliance with regulations. Electrochemical systems, on the other hand, have fewer moving parts and are designed for durability, leading to lower maintenance requirements and costs.

- Energy Efficiency: Modern electrochemical systems are engineered to be energy-efficient, consuming less power while producing high-purity chlorine gas. This not only reduces operating expenses but also aligns with sustainability goals by lowering the facility’s overall energy consumption.

Improved Environmental Sustainability

As industries, most notably the food and beverage industry, increasingly prioritizes environmental sustainability, the choice of disinfection methods becomes more critical. Electrochemical generation of chlorine gas offers several environmental benefits that make it a more sustainable option compared to traditional chlorine tank storage.

- Reduced Chemical Waste: Because chlorine is generated on-demand, there is no excess chemical to dispose of, which reduces waste and the environmental impact associated with chemical disposal. This also eliminates the need for handling and disposing of hazardous chlorine containers.

- Lower Risk of Environmental Contamination: The risks associated with chlorine gas leaks and spills are significantly reduced with electrochemical generation systems. By minimizing the storage of large quantities of chlorine gas, the potential for environmental contamination is greatly decreased.

- Carbon Footprint Reduction: The reduction in transportation needs—since chlorine gas is generated on-site—lowers the facility’s carbon footprint. Fewer deliveries mean less fuel consumption and a corresponding decrease in greenhouse gas emissions.

Scalability and Flexibility

Electrochemical generation systems offer a high degree of scalability and flexibility, making them suitable for a wide range of applications and facility sizes. This adaptability is a key advantage over traditional chlorine gas storage methods, which may require significant infrastructure and space to accommodate large tanks.

- Customizable Production Rates: Electrochemical systems can be tailored to produce the exact amount of chlorine gas needed for specific applications, allowing for efficient scaling based on the facility’s requirements. This flexibility ensures that the system can grow with the facility’s needs without requiring major upgrades or expansions.

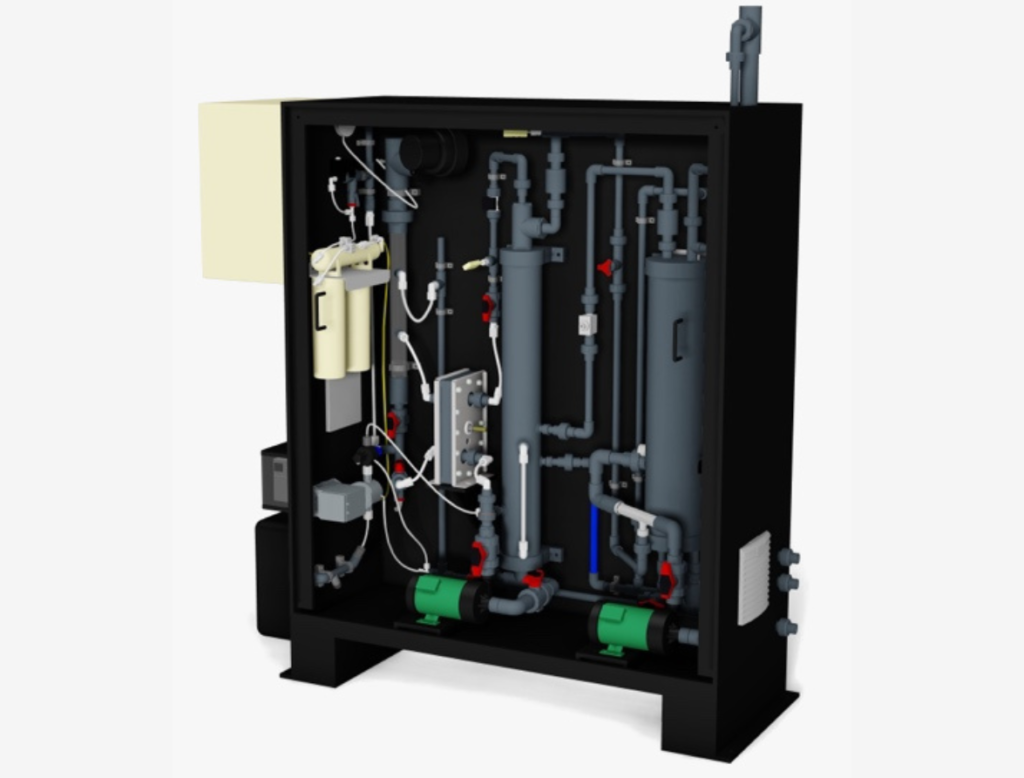

- Space Efficiency: Electrochemical generation systems are typically more compact than chlorine gas cylinders, freeing up valuable space within the facility. This is particularly beneficial for facilities with limited space or those looking to maximize the use of their existing infrastructure.

Compliance with Regulatory Standards

Chlorine gas storage is subject to stringent regulatory requirements due to the hazardous nature of the chemical. These regulations often impose significant compliance burdens on facilities, including the need for extensive safety measures, regular inspections, and detailed record-keeping.

- Simplified Compliance: Electrochemical generation systems simplify regulatory compliance by reducing the amount of chlorine gas stored on-site. This can lead to fewer regulatory hurdles, lower compliance costs, and reduced administrative burdens.

- Future-Proofing: As environmental and safety regulations continue to evolve, electrochemical generation systems offer a forward-looking solution that can easily adapt to new standards. This future-proofing ensures that facilities remain compliant without the need for costly retrofits or operational changes.

The shift from traditional on-site chlorine gas cylinder storage to electrochemical generation represents a significant advancement in water treatment and disinfection technology. By offering enhanced safety, operational efficiency, environmental sustainability, and regulatory compliance, electrochemical generation systems provide a compelling alternative for facilities seeking to modernize their disinfection processes.

If you’re considering transitioning to an electrochemical generation system or want to learn more about how this technology can benefit your facility, please reach out to us. Our team of experts is here to guide you through the process and help you make the best decision for your operational needs and sustainability goals.