EDI Water Treatment: How It Works and Where It Fits

Not all water treatment ends with chemicals or reverse osmosis. EDI water treatment—short for electrodeionization—is a sustainable, chemical-free method used to achieve ultrapure water in industrial settings where even trace ions, carbon dioxide, or residual salts can impact product quality.

At EAI Water, we help facilities across the U.S. navigate complex treatment decisions and select the right blend of technologies for their enhanced water purity needs. That includes evaluating when EDI systems make sense, and how to integrate it effectively alongside systems like reverse osmosis and ion exchange.

How Electrodeionization Works

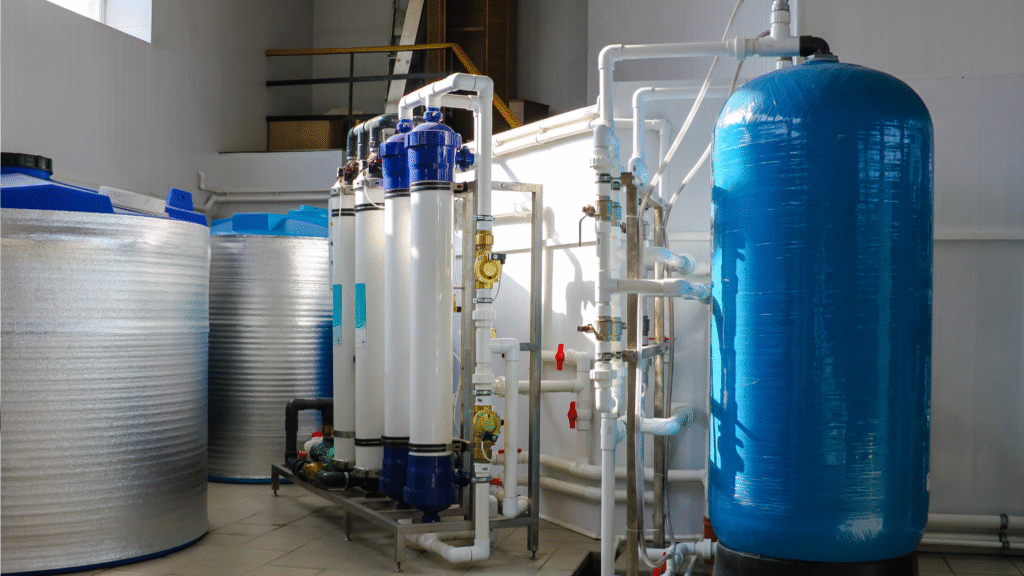

Electrodeionization systems (EDI) are an advanced water treatment technology that removes ionized and ionizable species from water using a combination of ion exchange resins, ion selective membranes, and an electrical potential.

Here’s what happens inside an EDI system process:

- Water first passes through a pre-treatment reverse osmosis system step, which removes the majority of dissolved solids.

- The partially treated feed water then enters the EDI cell, where it flows between chambers filled with ion exchange media.

- As water passes through, an electric field pulls cations and anions across the ion exchange membranes, removing them from the product stream.

- Unlike traditional ion exchange beds or softeners, the resins in EDI are regenerated continuously using electricity; no acid or caustic required.

The result is ultrapure water with resistivity levels reaching 16–18 MΩ·cm, suitable for the most demanding environments.

Where EDI Water Treatment Makes Sense

EDI systems are not universal solutions, but in the right application, they’re indispensable. EAI works with facilities to determine when this latest technology should be part of the treatment plan.

Typical use cases for electrodeionization (EDI) include:

- Pharmaceutical industry facilities requiring water that meets stringent purity standards

- Laboratories or cleanrooms where trace ions can disrupt processes

- Microelectronics manufacturing, where contaminants affect sensitive equipment

- Power plants using high-pressure boiler feedwater, where low conductivity is essential

EDI is almost always used as a post-RO polishing step, removing the last traces of ions, silica, and dissolved gases such as carbon dioxide that reverse osmosis alone can’t eliminate.

It’s also favored in facilities pursuing chemical-free operation or looking to reduce environmental risk tied to regenerant handling and discharge.

EDI vs. Traditional Ion Exchange Resin Systems

Many water treatment systems rely on ion exchange resins for softening or demineralization—but EDI water systems are a different class of technology. At EAI Water, we help facilities evaluate both options based on water quality goals, operational needs, and sustainability targets.

| Feature | Electrodeionization (EDI) | Ion Exchange Resins |

|---|---|---|

| Regeneration | Electrical, continuous | Chemical regeneration (acid/caustic) |

| Chemical Use | None | Moderate to high |

| Purity Level | Ultrapure (up to 18 MΩ·cm) | High-quality |

| Best Use Case | RO polishing | Softening, partial demineralization |

| Sustainability | High | Moderate |

Ion exchange – whether chemical regeneration occurs onsite or offsite – remains ideal for many boiler and cooling tower systems where selective removal of hardness ions is more economical. But for ultrapure applications, continuous electrodeionization offers unmatched performance with less downtime and waste.

How EAI Supports EDI-Integrated Systems

EAI has deep experience designing and supporting water treatment technology processes that include EDI. Our focus is building and integrating treatment trains that deliver both performance and longevity.

Our approach includes:

- Water quality assessments to determine if your incoming water and operational demands warrant EDI

- Designing pretreatment stages (like softeners and RO) to meet EDI feedwater quality requirements

- Supporting ongoing system monitoring, troubleshooting, and optimization to ensure long-term success

We also help clients decide when a customized ion exchange resin system may offer more flexibility or a better return on investment for their specific process water or boiler needs.

Your Partner in High-Purity Water Decisions

High-purity water systems aren’t one-size-fits-all. At EAI, we help you strike the right balance between performance, sustainability, and operational cost — whether that means incorporating electrodeionization, deploying custom ion exchange beds, or designing a hybrid solution tailored to your operation.

EDI only performs at its best when supported by a properly engineered pretreatment strategy. That’s why we start with comprehensive pretreatment solutions designed to ensure your upstream water quality meets the demands of high-purity systems.

Our team brings decades of field experience, system design expertise, and a results-driven approach that prioritizes chemical efficiency, water conservation, and long-term system performance.

Contact EAI todayand let’s build a smarter, cleaner water solution together.