Cooling Towers 101: How Does a Cooling Tower Work?

In Brief:

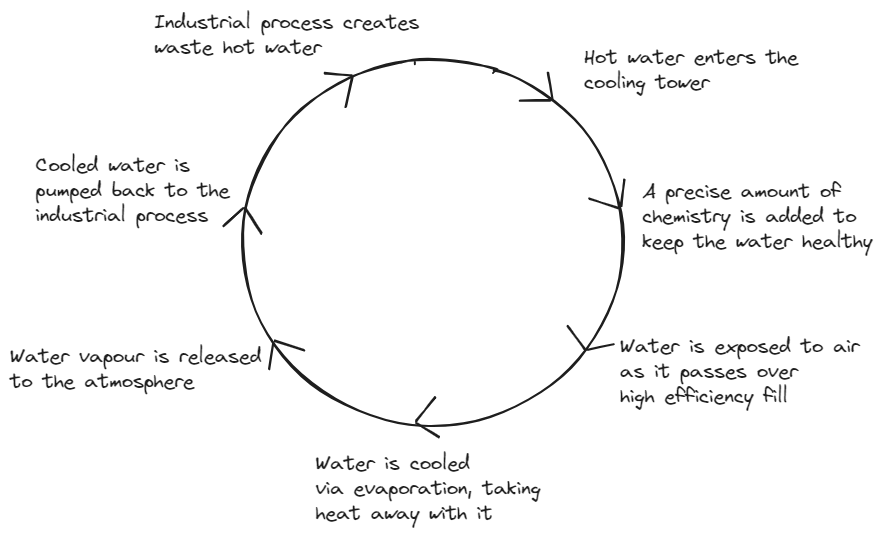

- Cooling towers work by bringing air into contact with heated water. This reduces the water’s temperature in a process known as evaporative cooling.

- Both natural drafts and mechanical fans can be used to cool water, which is then recirculated back into the industrial process where it begins the cycle again.

- The evaporated water takes heat away with it – however, this constant evaporation process leaves behind an accumulation of minerals, deposits, bacteria, scale, and other threats to water quality.

- The purpose of water treatment is to manage these threats within your cooling tower, by bleeding old water out, and adding chemistry to maintain equilibrium and improve the overall efficiency of the cooling system.

Cooling towers are heat exchangers that work by using an evaporative cooling process to transform hot water from industrial processes into cooled water. This cooled water can then be recirculated back into the system, completing the loop and providing cold water ready to be used again in all kinds of industrial processes.

Like many common heating and cooling processes, the inner workings of cooling towers are often shielded from view. But when you consider how critical temperature-controlled water is to industries like power generation, petrochemical manufacturing, healthcare, and food processing, it’s worth understanding how a cooling tower works – and how important it is to maintain water quality within the system.

Using a combination of physics, mechanical components, and plumbing, cooling towers work by taking unwanted heat and moving it to the atmosphere. This is vital for keeping manufacturing plants operating, offices cool and comfortable, and ensuring energy is efficiently transformed to help power our cities.

Types of Cooling Towers

Some cooling towers have a small, compact footprint and others – like those found on nuclear power plants – can dominate city skylines.

While they are used by a vast range of industries, the main drivers of cooling tower selection are the footprint – how much space you have to work with at your facility – and how many tons of cooling are required.

Using these factors, facility managers can then assess different brands and designs to determine the right cooling tower for their budget, keeping in mind long-term efficiency and maintainability.

Where are Cooling Towers Used?

- Power plants and energy generation: cooling furnaces and vacuum units

- Industrial applications: cooling air compressor water jackets, transformers and engine cooling systems

- Manufacturing: used for a wide range of cooling processes such as injection molding

- Steel refineries: used for cooling blast furnaces, rolling mills, and motors

- HVAC systems in Healthcare, Hospitality, Commercial Offices, and Higher Education: used for cooling heat pump water sources, chillers, AC systems and other auxiliary systems

The Heat Exchange Process

Heat exchangers come in all shapes and sizes, and can be constructed from a variety of fins, tubes, plates and channels. Cooling towers are one of the largest types of heat exchangers and are designed to reject waste heat by cooling water through either natural or induced drafts.

In the same way that you might blow air to cool down a hot cup of coffee, the heat exchange process inside a cooling tower is delivered by using natural drafts or fans to bring air into direct contact with hot water, reducing its temperature.

The cooled water is then pumped back to the condenser or process equipment where it begins the process again, absorbing heat and being pumped back to the cooling tower once again.

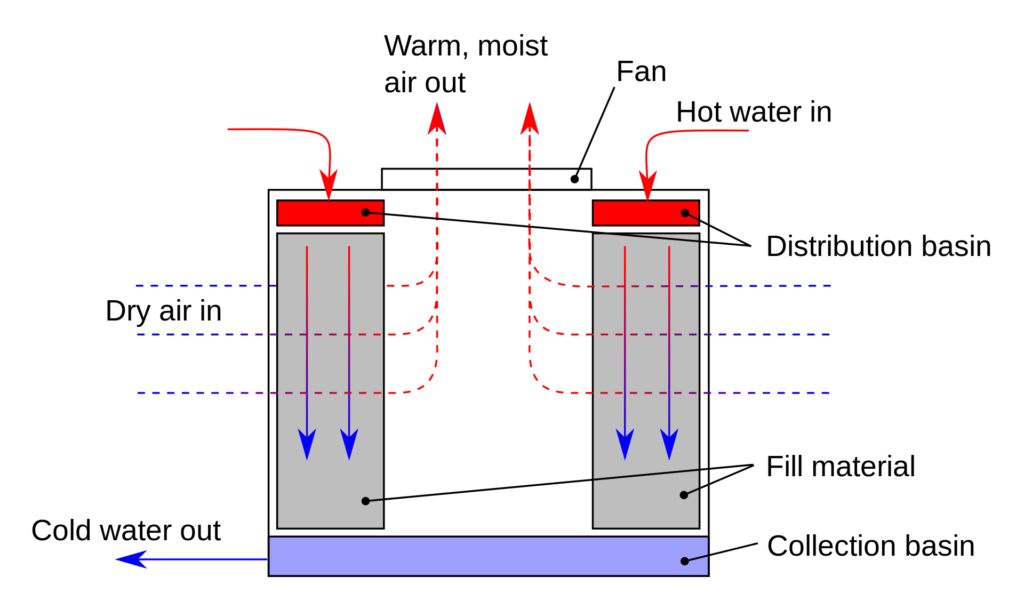

Induced draft crossflow type cooling tower. Crossflow diagram.PNG: Edreher (Diagram drawn by Eric Dreher with MSpaint)derivative work: Zerodamage – This file was derived from: Crossflow diagram.PNG:, CC BY-SA 3.0,

https://commons.wikimedia.org/w/index.php?curid=20683726

As air and water come into contact with each other during the cooling process, small volumes of water evaporate, which lowers the temperature of the water being circulated. The heat transferred to the air raises the air temperature and its relative humidity to 100%, which is then discharged to the atmosphere.

This series of repetitive inputs and outputs creates the continuous heat exchange process inside the cooling tower. Using this evaporative process results in significantly lower water temperatures than those that can be achieved with dry heat rejection.

This in turn delivers more cost-effective and energy-efficient operation of the systems being supported by the cooling tower.

Components of a Cooling Tower

The internal construction of a cooling tower can be complex, but every tower has four main components: a system to bring water in, a system to pipe water back out, some chemistry to maintain water quality, and in the middle, a ‘high-efficiency fill’ to circulate air through the water.

The most efficient method for cooling large volumes of water is to spread it out over a large surface area, which is where the fill component comes into play.

To achieve the best dissipation of heat throughout a tower, facilities will want to spread warm water out over the biggest area possible. High-efficiency fill is simply a means to achieve this: it’s typically a plastic material that spreads out the water to speed up evaporation, in the same way that a shallow puddle will evaporate faster than a deep pool.

An ancillary water treatment system is the other main part of a cooling tower: this system injects specific chemicals to ensure the water quality remains within set parameters.

The Importance of Water Quality

Like any volume of water that is in contact with the surrounding environment, the water within cooling towers is exposed to pathogens, accumulated deposits, and other threats that can reduce the efficiency of your entire cooling system and shorten the life of cooling tower equipment.

When systems aren’t adequately monitored and maintained, water quality drops and so does efficiency, creating a negative impact on production costs and equipment lifespan. By regularly monitoring cooling tower water and applying low-dose chemical treatment, one can reduce water use in your facility, lower energy costs, and minimize costly equipment repairs.”

Water treatment is vital to the good functioning of your cooling tower and it involves testing for levels of calcium, silica, iron, and other solids, bleeding the system to flush out these deposits, adding fresh water, and finally balancing the water levels with specific chemicals to achieve a predetermined water chemistry profile.

Although water treatment processes don’t remove 100% of deposits, they do restore your cooling tower’s water system to equilibrium.

Maintain Quality and Efficiency in Your Cooling Tower

A cooling tower is a sizable investment, so make sure you care for your asset by adhering to a professional water monitoring and treatment program. Partnering with a water treatment provider like EAI ensures your facility maintains clean, safe, and high-quality water for your operations.

For more information on how we can design the best water treatment solution for your facility, contact us here.