Cooling System Problems and their Impacts on Data Centers

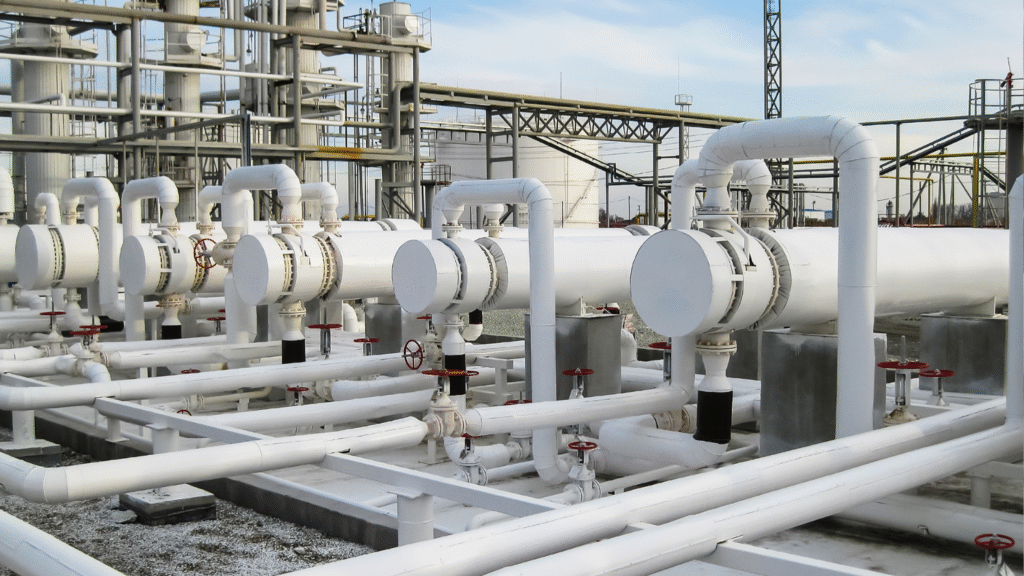

Cooling system problems are among the most critical yet underrecognized threats to data center performance. As demand surges from AI infrastructure, cloud computing, and video streaming, even minor disruptions in thermal regulation can cascade into major issues like reduced uptime, increased energy use, and premature equipment wear on critical infrastructure such as heat exchangers.

According to the 2024 U.S. Data Center Energy Usage Report, electricity consumption by U.S. data centers rose from 76 terawatt-hours (TWh) in 2018 to 176 TWh in 2023, now representing 4.4% of national usage. By 2028, projections show a potential increase to 325–580 TWh annually. This increase will be driven not only by compute load but also by how efficiently facilities remove heat.

The real problem is that many cooling system issues originate from internal biological fouling, poor water chemistry, corrosion byproducts, or inconsistent flow. These problems reduce thermal transfer efficiency, increase pressure drop across heat exchangers, and force equipment to work harder.

As part of EAI‘s “The Water Industry is All Industry” campaign, this article examines the most common cooling system problems facing modern data centers. Also, how expert-level water treatment can help resolve them before they compromise your infrastructure.

The Main Types of Cooling System Problems in Data Centers

Cooling systems in data centers are engineered for precision, yet even well-designed infrastructure is vulnerable to a range of performance-degrading problems. These issues often develop gradually, starting as minor inefficiencies and escalating into serious disruptions if left untreated. Understanding the most common types of cooling system problems is the first step toward prevention and performance recovery.

1. Scaling and Mineral Deposits

One of the most frequent culprits in cooling water systems is scale formation on heat exchangers. This refers to crystalline deposits of hardness salts such as calcium carbonate or magnesium hydroxide. These deposits typically form on heat exchanger surfaces due to chemical reactions triggered by high temperatures or shifts in pH. Over time, scale acts as an insulating fouling layer, reducing heat transfer efficiency and narrowing flow channels as the deposit thickness remains constant.

2. Biofouling and Microbial Growth

Biological fouling occurs when microbial colonies form sticky biofilms on internal surfaces, especially in low-flow or nutrient-rich zones. This type of deposit not only impairs thermal conductivity but can also create favorable conditions for corrosion and blockages.

3. Corrosion Product Accumulation

Corrosion fouling stems from the degradation of base metals like carbon steel, which releases rust or metallic oxides into the process fluid. These particles can settle in stagnant zones, further compounding flow restrictions and increasing pressure drop across cooling equipment.

4. Particulate and Sedimentation Fouling

Dust, debris, and suspended solids (often introduced through makeup water or airborne intake) can accumulate as fouling deposits in open-loop cooling systems. Without proper filtration or chemical dispersion strategies, these particles adhere to heat transfer surfaces and impede system efficiency.

Even thin layers of buildup from any of these sources can significantly reduce cooling performance. That’s why addressing particulate fouling mechanisms and deposit accumulation early is essential to avoiding larger system failures.

What Triggers Cooling System Problems?

Cooling system problems rarely stem from a single cause. Instead, they often develop through a complex interaction of water chemistry, material compatibility, environmental exposure, and mechanical design. When these factors align under the wrong conditions, they create the perfect storm for scale, biofouling, corrosion, or deposit formation to take hold.

Some of the most common triggering factors include:

Low Flow Rate or Uneven Distribution

Insufficient water velocity allows suspended particles and microbial colonies to settle on solid surfaces. Flow stagnation is particularly common in oversized loops or poorly balanced systems, creating an environment where fouling deposits can begin forming.

Temperature Fluctuations and Localized Hot Spots

Data centers often experience uneven thermal loads, especially in high-density server environments. These temperature fluctuations affect the solubility of hardness salts and increase the likelihood of scaling and thermal resistance buildup on heat exchanger surfaces.

Water Chemistry Imbalance

If cooling water is not properly treated, dissolved minerals, biological nutrients, and oxygen can trigger a variety of reactions. These lead to scaling, chemical reaction fouling, or corrosion. Each one of these issues is capable of generating layers of unwanted material on internal surfaces.

Environmental Contaminants

Facilities located in dry, dusty climates or near industrial zones often pull in airborne particulates that settle into cooling tower basins or air-cooled chillers. Over time, this can initiate the fouling process and increase sedimentation.

Material Incompatibility

Mixing different metals in cooling systems such as aluminum components paired with carbon steel can create galvanic corrosion, leading to surface roughness, scaling, and degradation of the underlying metal.

Even when systems are designed correctly, minor lapses in maintenance or monitoring can allow these conditions to develop. The earlier these issues are identified, the more effective and cost-efficient the corrective actions.

The Risks: How Cooling System Problems Impact Data Center Operations

In data centers, uptime and thermal balance are non-negotiable. But when cooling system problems arise, the consequences can be both immediate and compounding. What begins as a minor drop in efficiency can escalate into thermal bottlenecks, mechanical stress, or even catastrophic failure.

Heat Transfer Efficiency Degradation

When fouling layers form on heat transfer surfaces, they act as insulators, blocking efficient energy exchange between hot fluid and coolant. This forces the system to operate at higher speeds or temperatures to compensate, increasing overall thermal resistance and decreasing the ability to maintain optimal server temperatures.

Increased Pressure Drop and Flow Disruption

The buildup of fouling deposits narrows flow channels within piping and across heat exchangers, causing increased pressure drop. This stresses water pumps and limits coolant circulation, contributing to uneven temperature control across racks or data halls.

Rising Energy Consumption and Operating Costs

When cooling systems must work harder to maintain temperature setpoints, they draw more power. A small decline in efficiency due to biofouling or corrosion can raise energy consumption significantly. This impacts both operational costs and sustainability goals.

Accelerated Wear and Catastrophic Failure Risk

As stress accumulates on heat exchanger components, radiator hoses, pumps, and fans, so does the risk of system failure. Under persistent thermal load, degraded equipment may fail without warning. As a result, this causes downtime, potential SLA violations, and costly emergency interventions.

These risks are magnified in high-density or hyperscale facilities where even a single degree of temperature deviation can affect hardware reliability.

Energy Waste and Lifecycle Cost Consequences

Cooling system problems don’t just affect day-to-day operations. Instead, they quietly erode efficiency and infrastructure value over time. When systems are forced to overcompensate for poor heat transfer, flow restrictions, or fouling deposits, the result is sustained energy waste and accelerated wear.

Energy Inefficiency Becomes the Norm

Every added layer of scale, biofilm, or corrosion acts as thermal insulation, making heat exchangers less responsive and forcing chillers and pumps to draw more power. Over time, what was once a clean heat transfer surface becomes coated with insulating material that directly interferes with heat flow.

Even a modest 5% drop in cooling efficiency can drive six-figure energy losses annually for hyperscale data centers.

Operational Strain on System Components

As energy use rises, mechanical stress increases across the entire cooling system. This added strain can lead to shortened equipment lifespan, increased maintenance cycles, and premature component failure.

The Cost of Corrective Measures

If left unmanaged, many cooling system problems require expensive interventions. Invasive chemical cleaning, unplanned equipment shutdowns, or full system replacements may become necessary to restore capacity. Chemical cleaning programs also carry risks of damaging the underlying metal if performed too aggressively or too frequently.

What makes these costs especially difficult to justify is that they’re often avoidable had the early warning signs been addressed with proper monitoring and water treatment strategies.

Water Consumption and Environmental Pressures in the Data Center Industry

Data centers are drawing increased scrutiny not just for energy use, but for water consumption as well. Cooling system problems often exacerbate this footprint by requiring additional cycles, system flushes, or chemical rebalancing — leading to higher overall water demand.

In fact, according to the U.S. International Trade Commission, the volume of global digital data is expected to increase 146-fold between 2010 and 2025, fueling an urgent need for more data center infrastructure. With more than 5,300 facilities in the U.S. alone, the round-the-clock operation of servers, storage systems, and network hardware has made cooling systems a critical component and a significant source of water consumption.

Where the Water Goes

Water is consumed in two primary ways within data center operations:

- Indirectly, through electricity generation that powers the facility, much of which comes from thermoelectric plants with high water demands.

- Directly, as cooling water or process fluid in evaporative or liquid-based systems used to regulate equipment temperature.

These systems rely on tightly controlled water chemistry. When untreated water is introduced without adequate pretreatment or monitoring, it can promote scaling, corrosion, and biological growth. This, in turn, raises the likelihood of fouling and reducing the longevity of cooling equipment.

Case in Point: Google in The Dalles

In 2021, Google’s local data centers in The Dalles, Oregon reportedly consumed over 355 million gallons of water. It was more than a quarter of the town’s annual supply and over triple their usage just five years earlier. This illustrates a broader concern: as cooling infrastructure struggles to keep pace with thermal demands, the need for additional bulk fluid input increases.

Despite growing regulatory and public attention, many facilities still lack visibility into site-specific consumption. Without this data, operators face difficulty in benchmarking efficiency or defending sustainability claims.

This boils down to the fact that poorly managed cooling systems don’t just increase energy costs. They increase water risk as well. That makes proactive water treatment not only a technical necessity, but a sustainability imperative.

Industry Guidelines from ASHRAE and CRC Press

As cooling system problems gain visibility in the data center sector, industry standards are evolving to address their technical and operational risks. Organizations like ASHRAE, EPA and US Department of Energy offer in-depth guidance on managing heat exchanger fouling, maintaining system reliability, and improving thermal performance.

ASHRAE Recommendations for Data Centers

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) emphasizes the importance of comprehensive water treatment programs and routine system maintenance. Their guidance includes:

- Regular monitoring of water quality parameters, including pH, dissolved solids, and microbial activity

- Use of corrosion inhibitors and dispersants to control corrosion fouling and particulate accumulation

- Limiting the use of harsh chemical cleaning agents like hydrochloric acid to avoid damaging the underlying metal

These recommendations are especially critical for systems using liquid cooling, where even minor fouling can compromise thermal conductivity and lead to equipment throttling.

Cooling System Efficiency as a Competitive Metric

In the modern data center, cooling system efficiency is a core operational metric. Facilities are now benchmarked not only by IT load or Power Usage Effectiveness (PUE), but also by how reliably and sustainably they manage thermal load across critical infrastructure such as heat exchangers.

When cooling systems suffer from scaling, biofouling, or corrosion, the consequences ripple outward: uptime risk increases, energy consumption surges, and Service Level Agreements (SLAs) are put in jeopardy. Even small inefficiencies in heat transfer can lead to elevated core temperatures, reduced compute output, and premature hardware aging.

This shift in perspective has elevated cooling water quality and system reliability to mission-critical status for everyone connected. As cooling system problems grow more complex with the adoption of liquid cooling, edge computing, and distributed infrastructure, performance transparency becomes key. Operators who invest in early detection, and integrated monitoring gain a measurable advantage in uptime, cost control, and system longevity.

How EAI Supports the Data Center Industry

From managing water chemistry in heat exchangers to protecting high-value assets, our programs are engineered to address the full range of cooling system problems before it’s too late.

Integrated Chemical and Equipment Solutions

Our tailored treatment programs are built to:

- Prevent scale formation and corrosion fouling in high-temperature, high-load environments

- Disperse fouling deposits on heat exchangers before they accumulate in low-flow rate or low-velocity zones

- Reduce the need for aggressive chemical cleaning through consistent water stabilization and system oversight

- Extend asset life by protecting underlying metals, especially in mixed-material cooling systems

To complement our chemical solutions, we design and supply advanced industrial filtration equipment including reverse osmosis and electrodeionization skids, as well as fully enclosed containerized systems for remote or high-demand sites. These systems help maintain water system purity across evaporative cooling, closed-loop, and liquid cooling applications.

Support for On-Site Power and Thermal Systems

Many of our clients operate not only data infrastructure but also on-site power generation, including combined cycle systems and backup generators. That’s why EAI applies cross-sector expertise in water treatment for boilers, cooling towers, and condensers. We ensure consistent chemistry across interconnected cooling and energy platforms.

We also support reclamation and reuse of blowdown water where feasible, helping reduce makeup water demand and wastewater surcharges. This is especially valuable for facilities navigating water use restrictions or pursuing long-term sustainability targets.

Learn more about our Water Treatment for Energy and Power capabilities and how they extend to power-producing data center environments.

Designing for Reliability and Efficiency Starts with Water

As data centers expand to support AI, cloud platforms, and distributed computing, the challenge of cooling system problems grows more complex. Fouling, corrosion, scaling, and inconsistent water chemistry are now central concerns to energy efficiency, uptime, and system longevity.

With rising thermal loads and evolving infrastructure, reactive maintenance is no longer enough. Facilities need proactive water treatment strategies that address not just immediate issues, but long-term performance and reliability.

That’s why we partner with leading data centers to develop integrated programs that prevent scale, minimize corrosion, and support high-performance cooling. Whether you’re launching a hyperscale facility, modernizing legacy cooling systems, or managing a nationwide network of sites, EAI delivers the responsiveness, technical depth, and long-term support to keep your systems optimized.

Contact us to speak with an EAI expert or schedule a site-specific review with one of our water treatment experts.