Enhancing Water Quality with Commercial Reverse Osmosis Systems

In today’s industries, water quality is not just a convenience — it is a critical factor that influences product integrity, equipment longevity, and regulatory compliance. Whether in restaurants, laboratories, manufacturing plants, or power generation facilities, businesses rely on clean, pure water to operate effectively. Yet, tap water often contains dissolved solids, bacteria, and other contaminants that can compromise processes and products.

This is why a commercial reverse osmosis system is essential. Designed to purify water by removing impurities through a semi-permeable membrane, these systems deliver consistent, high-quality water tailored to the demanding needs of modern industries. By improving water quality, businesses can ensure smoother operations, protect equipment, and maintain high standards in their output, all while reducing waste and enhancing efficiency.

In this guide, we will explore how reverse osmosis systems work, why they are indispensable to businesses, and what features and maintenance practices help them perform at their best for many years.

Understanding Reverse Osmosis Systems

At its core, a reverse osmosis (RO) system is an advanced water filtration technology that removes contaminants, dissolved solids, and bacteria to produce clean, pure water. The process works by forcing water through a semi-permeable membrane that allows only water molecules to pass through, leaving impurities and particles behind.

How Reverse Osmosis Works

Water enters the system and passes through several filtration stages:

- Pre-treatment filters, such as sediment and carbon block filters, remove larger particles and chlorine that could damage the membrane.

- The water is then pressurized and pushed through the RO membranes, where the actual separation of contaminants occurs.

- Finally, the purified water is stored in a pressurized storage tank until it is needed, while the rejected impurities are flushed away as waste.

Components of a Reverse Osmosis System

A typical reverse osmosis system includes:

- Pre-filters to protect the membrane from other contaminants and sediment.

- The RO membrane, which is the heart of the system.

- A storage tank, often with a bladder, to hold treated water under pressure.

- Post-filters to polish the water before use.

This multi-stage filtration and separation process ensures the removal of harmful substances like iron, heavy metals, and bacteria, delivering high-quality water suitable for sensitive applications.

Learn more about the different parts of RO system in our blog: The Role of the Reverse Osmosis Tank in Water Purification Systems

Why Businesses Need a Commercial RO System

For many industries, water quality is directly tied to operational success. A commercial RO system helps businesses meet their specific needs for clean, reliable water by removing contaminants that could otherwise harm products, equipment, and processes.

Benefits of a Commercial RO System

Investing in a commercial RO system brings several advantages:

- Reliability and durability: These systems are constructed to handle high volumes of water and withstand demanding environments for many years.

- Efficiency: By minimizing waste and optimizing flow rates, businesses can reduce operating costs and improve sustainability.

- Consistent water quality: An RO system ensures water meets quality standards day after day, which is critical for industries like restaurants, laboratories, and manufacturing.

- Reduced downtime: With properly maintained equipment, businesses can avoid unexpected interruptions and maintain smooth operations.

Who Uses Commercial RO Systems?

Some of the industries that benefit from commercial RO systems include:

- Restaurants, which rely on purified water for cooking, beverages, and cleaning.

- Laboratories, where precise water purity is essential for experiments and testing.

- Power generation facilities, where water quality impacts energy efficiency and equipment longevity.

- Manufacturing, which depends on clean water for production processes and cooling.

For any business where water quality is a critical component of performance, a commercial RO system provides a robust solution that supports both short-term operations and long-term success.

Read more on our blog: Reverse Osmosis Water Treatment for Cooling Towers

Key Features of a Commercial Reverse Osmosis System

A commercial reverse osmosis system is more than just a filter — it is an engineered solution designed to meet the rigorous demands of modern industries. Understanding its standard features and optional upgrades helps businesses choose the right system for their needs.

Standard Features

Most commercial RO systems come equipped with components that ensure consistent performance and water quality:

- Advanced membrane technology: High-efficiency RO membranes effectively remove dissolved solids and contaminants while optimizing efficiency.

- Pre-treatment: Sediment and carbon block filters protect the membranes by removing larger particles, chlorine, and other impurities before they reach the core filtration stage.

- Pressurized storage tank: Treated water is stored under pressure, enabling immediate availability at the desired flow rates.

- Rotary vane pump: This critical component maintains consistent water pressure across the system to facilitate the RO process.

Additional Components

Some systems also include:

- Monitoring systems for pressure, flow, and water quality.

- Modular design for easy maintenance and specific needs.

- Durable construction with corrosion-resistant materials for a tough system that performs reliably over time.

These filters, membranes, and engineered components work together to produce high-quality water efficiently, meeting the demands of industries where water purity cannot be compromised.

Ensuring Performance, Maintenance, and Longevity

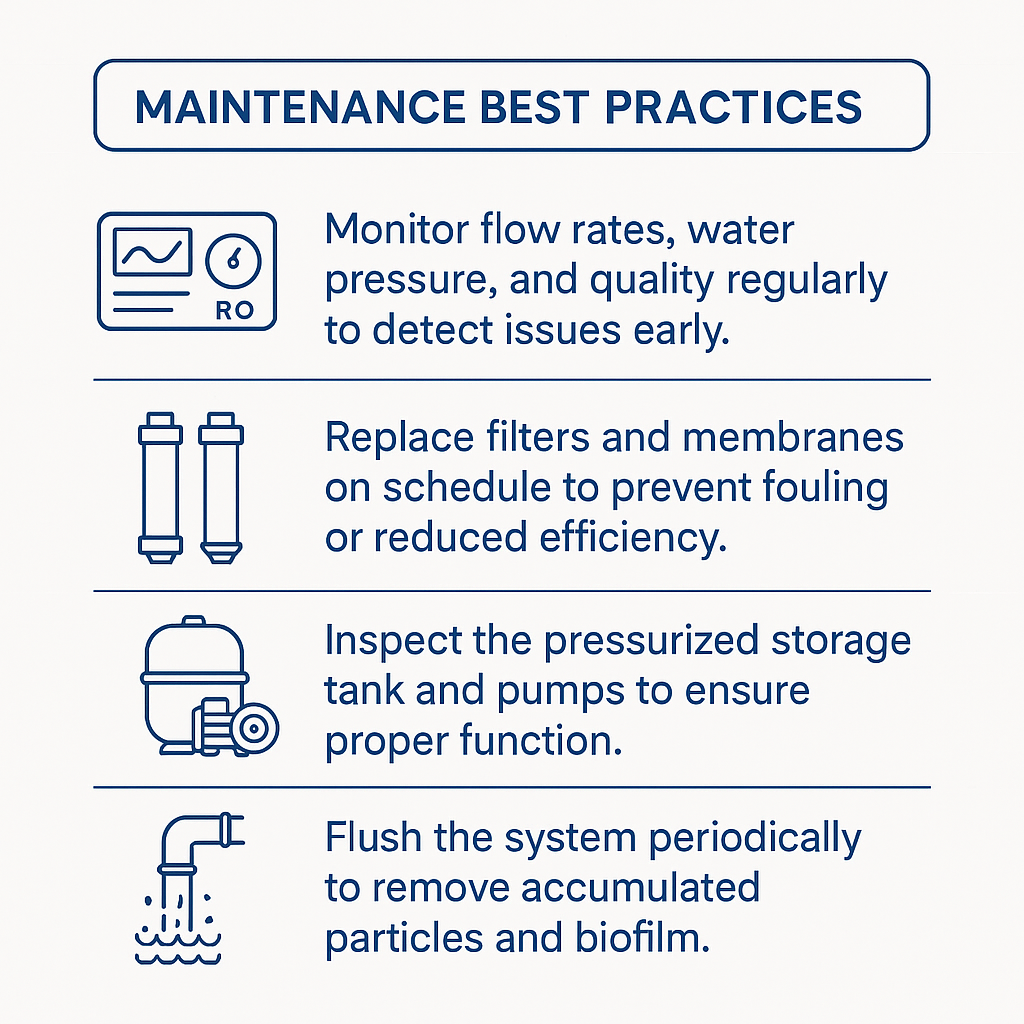

A commercial reverse osmosis system is a significant investment, and with proper care, it can deliver unmatched value and reliability for many years. Regular maintenance and optimization are essential to preserve performance and minimize downtime.

Maximizing Durability and Efficiency

A well-maintained system not only ensures consistent water quality but also protects your equipment and processes. Choosing a tough system, constructed from durable materials and designed for industrial use, helps minimize wear and tear. Keeping stock of spare parts and consumables on site can reduce response times during maintenance.

Support and Reliability

Working with a trusted provider ensures access to ongoing technical support, helping your team troubleshoot, upgrade, and optimize your RO system as needs evolve. This level of service maintains the quality and efficiency of your water treatment program while reducing risks associated with unplanned interruptions.

How EAI Supports Your Water Treatment Needs

At EAI, we know that every commercial reverse osmosis system must be designed to meet the specific needs of the business it serves. That’s why we provide tailored solutions backed by over 30 years of experience in water treatment.

Customized System Design

Our team of chemists and engineers begins with a thorough feedwater analysis to design a system that achieves your water quality and reliability goals.

We engineer and build robust, skid-mounted or containerized equipment that is:

- Durable and efficient

- Designed for high-demand environments

- Available in capacities from 15,000 to over 1 million gallons per day

Serving Diverse Industries

We’ve designed systems for a wide range of industries, including:

- Universities and convention centers

- Microelectronics and laboratories

- Breweries, beverage production, and restaurants

- Greenhouses, animal farms, and agriculture

Comprehensive Pretreatment and Post-Treatment

To protect your membranes, pumps, and downstream processes, we offer:

- Pretreatment: multimedia filtration, carbon filtration, water softening, dechlorination, and antiscalants

- Post-treatment: UV disinfection, pH adjustment, and brine reuse solutions

Ongoing Service and Maintenance

EAI keeps your system performing at its best with:

- Preventive maintenance plans

- Membrane cleaning skids

- Remote monitoring and diagnostics

- Membrane autopsy and cleaning services

When you choose EAI, you gain more than just a supplier — you gain a long-term partner committed to delivering reliable, high-quality water.

Learn more about our Industrial Reverse Osmosis Systems services.

The Value of Investing in a Commercial Reverse Osmosis System

Selecting the right commercial reverse osmosis system is a critical step toward achieving reliable, high-quality water for your operations. With the ability to remove impurities, bacteria, and other contaminants, these systems help businesses protect equipment, improve processes, and meet regulatory standards.

Whether you operate in manufacturing, laboratories, restaurants, or agriculture, investing in a properly engineered and maintained RO system ensures consistent water quality and supports long-term business success.

By understanding how these systems work, what features to prioritize, and how to maintain them, your business can optimize performance and extend the life of your water treatment equipment.

If you’re ready to enhance your water treatment program with a commercial RO system tailored to your needs, contact EAI today to speak with a water quality expert.

Frequently Asked Questions

What affects the sale price of a commercial RO system?

Several factors influence the cart sale price of a commercial reverse osmosis system, including capacity, level of automation, pretreatment requirements, and materials of construction. Systems built with higher-grade membranes, critical components, and robust bladder tanks tend to cost more but offer better durability and reliability.

Are commercial RO systems made in the USA?

Yes, many commercial RO systems are constructed and assembled in the USA, which often ensures better quality control, shorter ship times, and easier access to stock parts and technical support.

What is the difference between a pressurized and atmospheric tank in RO systems?

A pressurized storage tank holds treated water under pressure, ready for immediate use. An atmospheric tank, on the other hand, stores water at ambient pressure and usually requires a booster pump to deliver water to the point of use. Choosing between them depends on your flow rate and space considerations.

How does a commercial RO system handle different contaminants?

Commercial RO systems remove a wide range of impurities, including liquid and particulate contaminants, dissolved solids, iron, and particles. Pre-filters and post-treatment help target specific substances like chlorine, organics, and bacteria that might otherwise harm the system or reduce water quality.

What role does the RO system play in the overall water treatment process?

The RO system is a critical step in the water treatment process, acting as the main barrier against dissolved and suspended impurities. It works alongside pretreatment (such as water softeners or carbon filters) and sometimes post-treatment (like UV disinfection) to deliver high-quality water tailored to specific needs.

How do commercial RO systems facilitate maintenance and long-term use?

Many systems are designed to facilitate easy maintenance with modular components, clear line connections, and accessible filters. Keeping spare parts in stock and scheduling preventive service help ensure critical uptime and optimal performance.