Chlorine Generators for Bacteria Removal in Industrial Water Systems

Waterborne bacteria are a persistent – and often invisible – threat to industrial operations. Whether it’s in cooling towers, process water loops, or storage systems, microbial contamination can quietly degrade equipment, foul system efficiency, and create serious health and safety risks. In high-risk applications like food and beverage, data centers, and manufacturing plants, the presence of bacteria like Legionella, Pseudomonas, or sulfate-reducing organisms can’t be taken lightly.

Traditional disinfection methods – such as bulk chemical dosing, chlorine injection systems, or periodic shock treatments – often fail to deliver consistent control. These methods are prone to human error, fluctuating dose rates, and require manual handling of hazardous chemicals. In systems where uptime is critical and water quality is tightly regulated, inconsistent disinfection isn’t just inefficient – it’s a liability.

That’s where salt chlorine generators come in.

The Problem: Bacteria in Industrial Water Systems

Bacterial growth thrives in stagnant or slow-moving water zones, poorly maintained tanks, warm climates, and systems with inconsistent chemical dosing. The biofilm that forms from microbial buildup acts as a protective layer, shielding bacteria from further treatment and allowing colonies to flourish. This can lead to:

- Accelerated corrosion in piping and equipment

- Reduced heat transfer efficiency

- Clogged filters and fouled exchangers

- Higher chemical demand

- Legionella outbreaks and compliance failures

In industrial settings, these issues lead to increased maintenance costs, safety risks, and in some cases, shutdowns. What facilities need is a way to continuously and reliably dose disinfectant – without relying on hazardous material storage or complicated logistics.

What Is a Chlorine Generator?

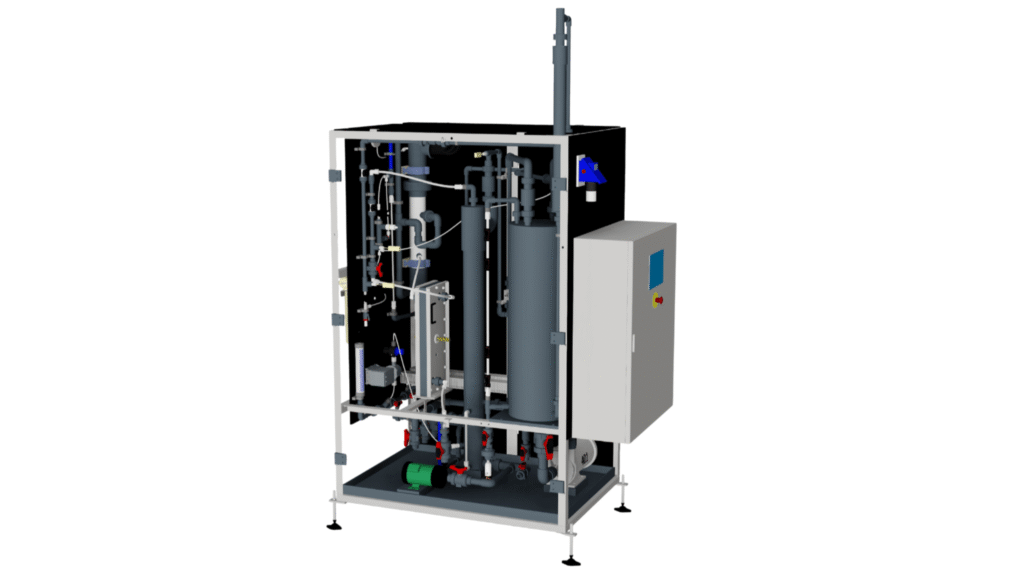

A chlorine generator is a system that produces chlorine disinfectant on-site, on-demand – typically through a process called electrochemical generation. This method uses salt (sodium chloride), water, and electricity to create a chlorine solution without the need to store or transport chlorine gas or bulk liquid.

Unlike chlorine injection pumps or manually added chemicals, chlorine generators:

- Eliminate the need for chlorine delivery and storage

- Reduce the risk of dosing errors

- Provide a consistent, controlled source of disinfectant in water treatment

- Allow for automation and integration into system-wide controls

The result is a safer, more reliable, and lower-maintenance disinfection strategy – especially for industrial systems that run 24/7 or experience frequent bacterial load fluctuations.

Learn more about how these systems work in EAI’s Electrochemical Chlorine Generator Overview.

Why On-Site Chlorine Generation Works Better

Chlorine loses potency over time. When it’s stored or transported, its disinfection strength and ability to kill bacteria drops due to exposure to air, light, and temperature changes. By generating chlorine right where it’s needed, these systems provide ideal supplies of treated water – without the risks of handling volatile chemicals.

For many facilities, this also means lower long-term costs, fewer regulatory headaches, and tighter control over water quality metrics and drinking water quality.

For a breakdown of how this method compares to traditional chlorine gas or liquid systems, see The Benefits of Electrochemical Generation of Chlorine Gas.

How Chlorine Eliminates Bacteria in Water Systems

Chlorine is a powerful and proven disinfectant, widely used across industries for its ability to neutralize a broad spectrum of pathogens, including bacteria, viruses, and protozoa in water supplies. Its antimicrobial action works primarily through oxidation – damaging the cell walls of microorganisms, disrupting metabolic processes, and ultimately rendering them inactive.

When chlorine enters water, it forms hypochlorous acid (HOCl), which is the most effective form of chlorine for disinfection. HOCl penetrates bacterial cell membranes quickly and efficiently, attacking internal structures and halting reproduction. This makes it particularly effective against both free-floating bacteria and those embedded in biofilms.

In industrial water supply systems, this level of performance is essential for disinfection purposes. Biofilms – slimy colonies of bacteria that cling to surfaces – are notoriously difficult to eliminate. They protect embedded bacteria from heat, biocides, and even ultraviolet (UV) systems. Chlorine, especially when freshly generated, has the residual power to break down these protective layers and maintain ongoing microbial control.

Integrating Chlorine Generators into Water Treatment Systems

Chlorine generators are not standalone devices – they’re integrated into the broader treatment process. In most industrial settings, chlorine is injected into the water stream just before or after a retention tank, which allows enough contact time for effective disinfection and safe water production.

System components may include:

- Inline chlorinators that inject the generated chlorine into process water

- Sensors and monitors to control dose rates based on real-time water flow or residual chlorine levels

- Retention tanks for ensuring adequate contact time

- pH control systems, which support chlorine’s disinfection performance

Because the chlorine is produced on-site and on-demand, dose rates can be precisely controlled based on system conditions – resulting in optimal performance and low maintenance. And since only a small amount of salt and electricity is needed, operational costs remain manageable.

Industrial Use Cases for Chlorine Generator Systems

Chlorine generators are already trusted across multiple industrial applications for bacteria removal and system disinfection in an array of water sources. Common uses include:

1. Cooling Towers

Cooling water systems are ideal environments for bacterial contamination due to warm temperatures, slow flow zones, and organic material buildup. Chlorine generators help control Legionella and other bacteria help with chlorination ithout relying on hazardous chemical storage.

2. Food and Beverage Processing

In industries where water quality directly impacts product safety, on-site chlorine generation provides clean, consistent disinfection for rinsing, process water, and CIP (clean-in-place) systems.

3. Industrial Well Water

Many facilities using well water require chlorine injection for high levels of iron, hydrogen sulfide, and bacteria contaminants. Chlorine generators can disinfect the water without overloading the system with liquid chlorine or pellets.

4. General Process Water

Manufacturers often deal with biofilm, slime-forming bacteria, and contamination in storage tanks, pumps, and piping. Chlorine generators help reduce downtime and cleaning intervals.

For a broader look at disinfection benefits, visit our article on Chlorine Generation in Industrial Settings.

What Makes This Method More Effective

Inline production and on-site chlorine injection gives facilities a critical edge – maximum disinfection strength, fewer byproducts, and more reliable results over time. Unlike UV systems, chlorine leaves a residual in the water, offering continued protection against bacterial regrowth as water moves through the system.

Explore more common questions in our FAQ on Onsite Chlorine Generation.

Why More Facilities Are Choosing Chlorine Generators

Industrial facilities face constant pressure to balance performance, safety, and cost. Chlorine generators offer a way to simplify bacterial control without compromising any of those priorities.

Here’s why they’re gaining traction in facilities across sectors:

1. Consistent, On-Demand Disinfection

Because chlorine is generated on-site, systems pump a steady and predictable disinfectant dose. There’s no drop-off in potency during transport, storage, or chlorine injection, and operators have full control over chlorinator production rates. This ensures bacteria and other pathogens are continuously kept in check – even during system fluctuations.

2. Lower Chemical Handling Risks

Bulk chlorine storage, transport, and manual dosing all introduce hazards. On-site generation systems eliminate the need to store liquid chlorine, chlorine pellets, or gas cylinders – reducing operator risk and simplifying compliance.

3. Reduced Operating Costs Over Time

Once installed, chlorine generators rely on inexpensive, widely available salt and a small amount of electricity. Many systems run for years with minimal maintenance, and since the output is consistent, chemical waste is minimized. The result: predictable costs, fewer chemical deliveries, and less labor-intensive maintenance on equipment features.

4. Environmental and Safety Advantages

By avoiding high-concentration chemical storage and transport, chlorine generators reduce a facility’s environmental footprint related to sanitation. There are fewer emissions, fewer packaging materials, and no hazardous waste – making it easier to align with corporate sustainability goals and ensure proper chlorine injection.

Important Considerations Before Implementation

While chlorine generators offer significant advantages, they aren’t plug-and-play for every system. Before committing, facilities should evaluate:

- Water chemistry: The presence of certain ions or high iron, sulfur, or pH contaminant levels may require pre-treatment to optimize disinfection.

- System demand: Chlorine generation capacity must match peak water flow and bacterial load. Undersized chlorination units will underperform.

- Space and layout: Systems require appropriate placement for salt storage, access, ventilation, and integration into existing infrastructure.

- Staff training: Though maintenance is low, operators should understand how to monitor residual chlorine, adjust dose rates, and perform routine checks.

For systems with complex demands or legacy infrastructure, partnering with a provider like EAI ensures all design, sizing, and compliance considerations are handled correctly.

When Is a Chlorine Generator the Right Fit?

If your facility struggles with:

- Inconsistent disinfection results

- Manual chlorine dosing or safety concerns

- Bacterial fouling or biofilm formation

- High operating costs from bulk chemical use

…then an on-site chlorine generator could be the most efficient long-term solution. These systems are especially well-suited for high-throughput, 24/7 industrial processes where water quality directly affects performance, safety, or regulatory compliance.

Get Expert Support from EAI

EAI helps industrial clients design and deploy chlorine generator systems that match their unique needs – from small-scale installations to complex multi-loop process systems. If you’re exploring options for bacteria removal, pathogen control, or broader water treatment upgrades, we’re ready to help.

Talk to our water treatment experts today to see if chlorine generation is right for your system.