Chlorine Dioxide Generators

Chlorine Dioxide Solutions

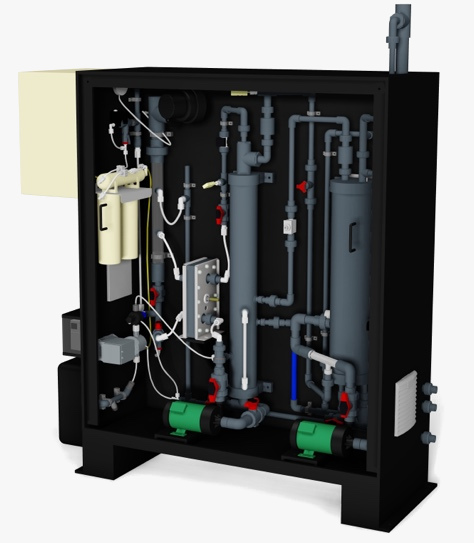

EAI Water is proud to design, manufacture, and service the industry-leading onsite chemical generator in the United States. We design and build site-specific generators for chlorine and chlorine dioxide using single chemical (1-chem) precursors technology geared towards best-in-class operations, safety, and performance. Our generators produce either gaseous, liquid, or combined solution chlorine dioxide at the highest purities demanded by customers who are safeguarding food and beverage products and human health.

What is Chlorine Dioxide?

Chlorine dioxide (ClO₂) is a versatile disinfectant used for potable water treatment, food and beverage processing, and industrial water circuits. EAI Water’s on-site generation systems provide effective disinfection with minimal by-products and operate independently of pH variations.

Applications of Chlorine Dioxide

Chlorine dioxide (ClO2) stands out as a powerful and versatile disinfectant, suitable for various applications:

- Potable Water Disinfection: Chlorine dioxide ensures that drinking water is safe by effectively eliminating harmful microorganisms without forming trihalomethanes (THMs) and producing very low levels of adsorbable organic halides (AOX). This makes it an ideal choice for municipal water treatment facilities or healthcare facilities seeking to comply with stringent health and safety regulations.

- Food and Beverage Industry: In the food and beverage sector, water used for washing and as an ingredient must meet high hygiene standards to ensure product safety. Chlorine dioxide is particularly effective in this context due to its strong biocidal properties and the fact that it does not form harmful by-products such as chlorates, making it safe for use in food-related applications.

- Industrial Water Circuits: Industrial processes often face challenges related to bacterial slime and biofilm formation in water circuits, which can reduce efficiency and increase maintenance costs. Chlorine dioxide is highly effective in controlling bacterial slime and biofilm, thereby improving the operational efficiency of cooling towers, heat exchangers, and other industrial water systems.

Benefits of Chlorine Dioxide

Chlorine dioxide offers several significant advantages over traditional disinfectants, making it a preferred choice for various water treatment applications:

- Simple and Compact Dosing Systems: The equipment required for generating and dosing chlorine dioxide is relatively simple and compact, making it easy to integrate into existing water treatment systems. This simplicity translates into lower capital and operational costs and ease of maintenance.

- No THMs Formation: One of the primary benefits of using chlorine dioxide is that it does not produce trihalomethanes (THMs), which are harmful by-products commonly formed when chlorine reacts with natural organic matter in water. THMs are regulated in many water supplies due to their potential health risks, including cancer and liver, kidney, or central nervous system problems.

- Very Low AOX Levels: Chlorine dioxide generates very low levels of adsorbable organic halides (AOX), which are organic compounds that can be harmful to the environment. This characteristic makes chlorine dioxide an environmentally friendly option for water disinfection.

- pH Independence: The effectiveness of chlorine dioxide as a disinfectant is largely unaffected by the pH of the water, maintaining its biocidal properties across a wide pH range (5 to 9). This contrasts with chlorine, whose effectiveness decreases significantly at higher pH levels.

- On-Site Generation: Chlorine dioxide is generated on-site due to its reactive nature. This requirement ensures that fresh, potent disinfectant is always available, reducing the risks associated with the transportation and storage of hazardous chemicals. On-site generation also allows for precise control over the dosing and application of chlorine dioxide.

SECONDARY DISINFECTION

Treatment of drinking water for hospitals protects facilities from the unwanted risk of legionella and other pathogen infiltration.

THERMAL STORAGE

Management of large storage tanks with chlorine dioxide minimizes microbial growth in stagnant systems.

FOOD AND BEVERAGE

Chlorine dioxide is a proven disinfectant for food and beverage manufacturing, while minimzing by-product formation like those found with chlorine treatment.

OUR EXPERTS ARE WAITING TO HEAR FROM YOU.

Reach out to learn more about saving time and costs with on-site chlorine dioxide generation.

Types of Chlorine Dioxide Generators

EAI Water offers a single-chem precursor chlorine dioxide generation systems designed to meet diverse application needs. This system has unique features and benefits tailored to specific water treatment requirements, yet is always focused on ensuring safety and operational uptime.

- Single-Chem Electrochemical Systems: EAI’s proprietary chlorine dioxide systems generate chlorine dioxide using an electrochemical process that converts chlorite ions into chlorine dioxide. The electrochemical system uses only a single precursor, Electricide, and is known for its high purity and efficiency, producing chlorine dioxide at 95-99% purity with over 80% chlorite conversion. This method is ideal for applications requiring high-quality chlorine dioxide with minimal by-products. In addition, the single chem precursor model requires no storage of hydrochloric acid on site, and thus dramatically reduces risk to human health and the environment.

- Chlorine Dioxide Generation Reactions:

- ① Anode (oxidation): ClO2– → ClO2 + e–

- ② Cathode (reduction): 2H2O + 2e– → H2 + 2OH–

- ① + ② (combined) 2ClO2– + 2H2O → 2ClO2 + H2 + 2OH

Properties and Generation of Chlorine Dioxide

Properties and Generation of Chlorine Dioxide

Chlorine dioxide (ClO2) is a yellow to brown gas at room temperature, known for its strong oxidizing properties. Due to its highly reactive nature, chlorine dioxide must be generated on-site using proprietary reaction and dosing equipment. Solubility and reaction method are key considerations for the generation of chlorine dioxide.

Solubility

Chlorine dioxide is approximately five times more soluble in water than chlorine and fifty times more soluble than ozone. This high solubility ensures effective dispersion and disinfection in water systems. In closed pipelines, there is virtually no loss of ClO2 into the gas phase. However, in open tanks, the concentration of ClO2 in solution will gradually decrease until equilibrium is reached between ClO2(g) and ClO2(aq).

How Does A Chlorine Dioxide Generator Work?

There are several methods to generate chlorine dioxide. EAI’s generator for example, generates chlorine through a unique, electrochemical generation method. This method is superior to other chlorine dioxide mixing devices (oftentimes mislabeled as generators) that utilize acid or other dangerous chemicals as a precursor to form chlorine dioxide.

Generation Methods:

- Electrochemical Reaction (EAI generator): This method involves the electrochemical oxidation of chlorite ions to chlorine dioxide. The process is efficient and produces high-purity ClO2 with minimal by-products. The reactions involved are:

- Anode (oxidation): ClO2– → ClO2 + e–

- Cathode (reduction): 2H2O + 2e– → H2 + 2OH–

- Combined: 2ClO2– + 2H2O → 2ClO2 + H2 + 2OH–

- Acid-Chlorite Reaction: In this method, sodium chlorite reacts with hydrochloric acid to produce chlorine dioxide. This reaction is driven to completion by using an excess of acid:

- 5NaClO2 + 4HCl → 4ClO2 + 5NaCl + 2H2O

- Chlorine-Chlorite Reaction: This method combines chlorine gas with sodium chlorite to generate chlorine dioxide. The process involves two steps:

- 2NaClO2 + HOCl + HCl → 2ClO2 + 2NaCl + H2O

Generation Yield and Running Costs

The efficiency of chlorine dioxide generation varies depending on the method used. Here are some considerations for each method:

- 2-Chemical Acid-Chlorite Systems: These systems typically achieve a chlorite yield of 65-68%. While suitable for low-capacity generation, their overall conversion efficiency may be lower due to unreacted acid. This makes them cost-effective for smaller applications but less efficient for higher output needs.

- Chlorine-Chlorite and Three-Chemical Systems: Both methods offer high conversion efficiency, ranging from 95-98%. These systems are well-suited for higher capacity requirements, providing a reliable and consistent supply of chlorine dioxide.

- Electrochemical Systems: Electrochemical generation of chlorine dioxide using Electricide® systems produces ClO2 at 95-99% purity with over 80% chlorite conversion. This method is cost-effective, with high overall chemical conversion efficiency due to the use of a single precursor chemical.

Generation Modes: Continuous and Contiguous

Chlorine dioxide generators can operate in either continuous or contiguous modes, depending on the specific needs of the application:

- Continuous Mode: In this mode, chemicals are continuously added to the reaction chamber, and the generated chlorine dioxide is directly dosed into the water stream. This method ensures a steady and constant supply of ClO2, suitable for applications requiring uninterrupted disinfection.

- Contiguous Mode: In this mode, chlorine dioxide is generated into a storage tank at high concentrations (2000-5000 ppm) and then dosed into the water system as needed. This approach allows for flexible dosing and is ideal for applications with variable demand.

Disinfection Efficacy

Chlorine dioxide is a powerful disinfectant, capable of inactivating a wide range of microorganisms, including bacteria, viruses, spores, and molds. Its efficacy is consistent across a broad pH range (5 to 9), making it an ideal choice for various water disinfection applications. Unlike chlorine, which loses effectiveness at higher pH levels, chlorine dioxide maintains its disinfection properties regardless of the water’s pH, ensuring reliable pathogen control.

Microbial Reduction Data: Here are some specific examples of chlorine dioxide’s efficacy in reducing microbial contamination:

Bacterial Reduction Using Chlorine Dioxide:

| Micro-organisms | ppm of ClO₂ | Contact Time (s) | Inactivation (%) |

| Staphylococcus aureus | 1 | 60 | 99.999 |

| Escherichia coli | 0.15 | 300 | 99.9 |

| Escherichia coli | 0.25 | 60 | >99.999 |

| Streptococcus | 1 | 15 | >99.999 |

| Lactobacillus brevis | 0.15 | 300 | 99.9 |

| Lactobacillus brevis | 1 | 300 | >99.999 |

| Pseudomonas aeruginosa | 1 | 60 | >99.999 |

Fungicidal Activity of Chlorine Dioxide:

| Micro-organisms | ppm of ClO₂ | Contact Time (min) | Inactivation (%) |

| Saccharomyces diastaticus (yeast) | 0.15 | 10 | 99.9 |

| Saccharomyces diastaticus (yeast) | 1 | 1 | >99.999 |

| Saccharomyces diastaticus (yeast) | 0.5 | 10 | >99.999 |

| Saccharomyces diastaticus (yeast) | 1 | 1 | >99.999 |

| Penicillium expansum (mould) | 0.5 | 60 | 99.99 |

| Penicillium expansum (mould) | 2 | 20 | 99.999 |

| Pediococcus damnosus (yeast) | 0.15 | 20 | 99.99 |

| Pediococcus damnosus (yeast) | 0.3 | 5 | 99.99 |

| Pediococcus damnosus (yeast) | 1 | 5 | 99.999 |

| Pectinatus cerevisiiphilus (yeast) | 0.1 | 5 | 99.9 |

Reaction By-Products

When chlorine dioxide reacts with naturally occurring organic matter (NOM) in water, it forms oxidized organic compounds such as carboxylic acids and aldehydes, typically at ppb (parts per billion) levels. Importantly, no chlorinated organic by-products are formed unless chlorine is present in the reaction mixture. The major inorganic by-product is chlorite, which typically constitutes 40-60% of the reacted chlorine dioxide.

Safety and Measurement

Handling and measuring chlorine dioxide require careful consideration due to its reactive nature and potential hazards. Here are the key aspects of safety and measurement:

- Safety Considerations: Chlorine dioxide gas can be dangerous if its concentration in air exceeds the explosive threshold of 10% v/v. EAI Water’s chlorine dioxide generators are designed to prevent the accumulation of high-concentration gas, ensuring safe operation, with automatic shutoff and sensor redundancy to ensure there are no risks to operators and facilities.

- Measurement of Residual Chlorine Dioxide: The residual chlorine dioxide in water can be measured using a comparator or photometer with DPD1 reagent. This method is straightforward for the electrochemical process since no chlorine is present with the chlorine dioxide. However, in non-electrochemical processes, treated water will contain both chlorine and chlorine dioxide. Since both species react with DPD1, differentiating just chlorine dioxide can be challenging. In such cases, the preferred testing method is with Lissamine Green B reagent, which is not cross-sensitive to chlorine, ensuring accurate measurement of chlorine dioxide levels.

Reactions with Inorganic Compounds

Chlorine dioxide is highly reactive and interacts with various inorganic compounds in water, providing specific benefits depending on the application:

- Ammonia Nitrogen: Chlorine dioxide does not react with ammonia nitrogen. This non-reactivity is advantageous in water disinfection applications where ammonia is present, such as in some cooling towers or wastewater systems. Chlorine dioxide remains effective for disinfection in these scenarios without the complications associated with ammonia-chlorine reactions.

- Iron: Iron is commonly present in groundwater and industrial wastewater as ferrous ion (Fe2+) or in compounds containing ferrous ion. Chlorine dioxide effectively oxidizes ferrous ion to ferric hydroxide (Fe(OH)3), which precipitates out of solution. This reaction is pH-independent and occurs rapidly, making chlorine dioxide ideal for treating iron-contaminated water. By dosing ClO2 at a rate of 1.2 parts per part of iron, the oxidation and removal of iron are efficient, preventing issues such as brown staining of clothes and bacterial regrowth.

- Manganese: Manganese, often found in groundwater as Mn2+ ion, can be effectively removed using chlorine dioxide. ClO2 oxidizes Mn2+ to manganese dioxide (MnO2), which precipitates out. This reaction is fast, ensuring that MnO2 forms before the water reaches filters or settling tanks, preventing black staining in the distribution system. Additionally, chlorine dioxide avoids the formation of permanganate, unlike ozone, which can produce a pink color in water when overdosed. The required dose of chlorine dioxide is 2.45 parts per part of manganese. When manganese is bound in humic complexes, chlorine dioxide can break these complexes and oxidize the Mn2+.

- Sulfur Compounds: Chlorine dioxide can fully utilize its oxidizing power to convert sulfides (H2S) and mercaptans to sulfate ion (SO4^2-), avoiding the formation of colloidal sulfur, which is a common issue with chlorine and ozone.

- Cyanide: Chlorine dioxide can only oxidize cyanide (CN-) to cyanate ion (OCN-). For complete oxidation of cyanide to nitrogen gas (N2) and carbonate ion (CO3^2-), chlorine is preferred over chlorine dioxide.

- Phenols: Chlorine dioxide can be effective in destroying phenols in wastewater as it is a strong oxidizing agent and is used in water treatment for its ability to oxidize various organic contaminants, including phenolic compounds. The process involves the oxidation of phenols to less harmful substances, which can then be further treated or removed.

pH Independence

One of the main advantages of using chlorine dioxide for disinfection is its pH independence. Unlike chlorine, which hydrolyzes to hypochlorite ion and loses effectiveness at higher pH levels, chlorine dioxide inactivates pathogenic microorganisms at the same rate between pH 5 and 9. This makes chlorine dioxide an ideal choice for disinfecting potable water and process water with varying pH levels, ensuring consistent and reliable disinfection.

Reduced Chlorate Concerns with Disinfection

Chlorine dioxide (ClO₂) is distinct from chlorine (Cl₂) and chlorinated compounds in its behavior during water treatment, primarily due to its different chemical properties and reaction pathways. Typical 12.5% (125 g/L) sodium hypochlorite comes immediately from the manufacturer with 1.5 g/L chlorate ion present. Here are some key reasons why chlorine dioxide typically does not form chlorates (ClO₃⁻) in significant amounts during water treatment:

1. Different Oxidation Pathways: Chlorine dioxide is a more selective oxidant compared to chlorine. While chlorine can form chlorates as part of its oxidation processes, chlorine dioxide tends to react differently with various contaminants. The primary reactions of chlorine dioxide involve oxidation of organic compounds and reduction to chloride (Cl⁻) or chlorite (ClO₂⁻) rather than chlorate.

2. Reaction Mechanism: In the presence of chlorine dioxide, the formation of chlorates is less favored. Chlorine dioxide primarily reacts to form chlorite ions (ClO₂⁻) and/or chloride ions, depending on the pH and other conditions. The formation of chlorates usually requires higher concentrations of chlorine and specific conditions, such as higher pH levels.

3. Reaction Conditions: Chlorine dioxide’s tendency to form chlorates is minimal under the typical conditions used in water treatment (e.g., neutral to slightly acidic pH). Chlorate formation is more commonly associated with sodium hypochlorite (bleach) under alkaline conditions.

4. Stability and Use: Chlorine dioxide is generally used in a controlled manner to minimize unwanted by-products. The oxidation process with chlorine dioxide is designed to target specific contaminants, reducing the likelihood of chlorate formation.

Overall, while chlorine dioxide can potentially form chlorates under certain conditions, it is less common and less of a concern compared to other chlorine-based disinfectants. The careful management of chlorine dioxide dosage and operational conditions helps to prevent the formation of unwanted by-products like chlorates.

No THMs Formation

Chlorine dioxide produced by EAI’s electrochemical process does not produce trihalomethanes (THMs) upon reaction with organic matter. THMs are regulated in most water supplies due to their potential health risks. The absence of THMs formation is a significant advantage of chlorine dioxide, making it a safer and more environmentally friendly disinfectant compared to chlorine.

We Can Provide You a Turnkey System

EAI Water offers turnkey systems including design drawings (P&ID, 3D model and GA), installation (mechanical and electrical), commissioning, and ongoing service support. Our engineering, manufacturing, and service team are all located in Vista, CA and we provide ongoing service to all 48 contiguous states, as well as Mexico and Canada. Each of our systems can be provided with an NSF certification and we have proven risk management protocols to ensure that the manufacturing, installation, commissioning, and ongoing operations are safe for customers.

Learn More: CDE Electrochemical Chlorine Dioxide Generators PDF

Typical Applications

The use of chlorine dioxide is limitless. However, some widely used applications include the following:

- Potable water disinfection

- Secondary disinfection of water entering healthcare facilities

- Beverage industry process water disinfection

- CIP sanitation as a replacement for peracetic acid

- Milk condensate (cow water) disinfection for re-use

- Water used for irrigation in greenhouses

- Waste water disinfection

- Thermal energy storage (TES) water

- Disinfestation of plant pathogens (phytophthora, pythium) for nursery irrigation water

- Vegetable and fruit washing

- Food industry process water disinfection

- Membrane (RO, NF, UF) sanitization

- Iron and manganese oxidation

- Cooling tower disinfection for Legionella destruction

- Cooling system macro and micro fouling control for fresh water and sea water circuits

For more information or to inquire about our chlorine dioxide solutions, please contact us here. Our expert team is ready to provide tailored solutions to meet your specific water treatment needs.