Understanding Chlorine Dioxide Generation: A Breakdown of the Technology

Chlorine dioxide (ClO₂) has emerged as a powerful and versatile disinfectant in various industrial and municipal water treatment applications over the past several decades. Its ability to control a wide range of pathogens, including bacteria, viruses, and protozoa, makes it an essential tool in maintaining water safety and quality. However, the effectiveness of chlorine dioxide is largely dependent on the method used to generate it. This article explores the technology behind chlorine dioxide generation, highlighting the methods, advantages, and practical considerations for optimal implementation. Additionally, we will showcase how EAI Water’s chlorine dioxide generators offer superior performance and reliability in various applications.

Chlorine Dioxide: A Potent Disinfectant

Chlorine dioxide is recognized for its broad-spectrum efficacy against a variety of microorganisms. Unlike traditional chlorine, ClO₂ doesn’t form harmful byproducts such as trihalomethanes (THMs) and haloacetic acids (HAAs). This characteristic alone makes it a preferred choice for water treatment, particularly in applications where maintaining water quality is critical. Understanding the different methods of chlorine dioxide generation is key to selecting the right system for your needs, and EAI Water is here to help you make that decision with confidence.

Methods of Chlorine Dioxide Generation

There are several methods for generating chlorine dioxide solution, each with its own set of advantages and considerations. Below is a comparison of the most common methods:

| Method | Process | Advantages | Considerations | Conversion Efficiency | Typical Applications |

| 2-Chemical | Reacting sodium chlorite with an acid (e.g., hydrochloric acid) or chlorine gas | Cost-effective, flexible production | Safety concerns with handling chemicals in reaction chamber, byproduct management | Moderate | Municipal water treatment, cooling towers |

| Electrochemical | Using an electrolytic cell to produce ClO₂ from a salt solution (sodium chlorite or sodium chloride) | High-purity ClO₂, minimal byproducts, safer to handle | Higher capital cost, regular maintenance required | High | Food processing, potable water, legionella control |

Operational Benefits of Chlorine Dioxide Generation

Regardless of the generation method chosen, chlorine dioxide offers several key benefits for water treatment:

- High Disinfection Efficacy: Chlorine dioxide is effective at low concentrations, meaning less chemical is required to achieve the desired level of disinfection. This makes it particularly valuable in applications where water quality is paramount, such as in drinking water treatment, cooling towers, and food processing.

- Minimal Impact on Water Chemistry: One of the standout features of chlorine dioxide is its stability across a wide pH range. Unlike traditional chlorine, which can cause fluctuations in water pH, ClO₂ maintains consistent disinfection performance without altering the water’s pH balance. This reduces the need for additional chemical adjustments post-treatment.

- Enhanced Safety: For facilities concerned with safety, particularly regarding chemical handling, chlorine dioxide generation—especially through electrochemical methods—offers a safer alternative. The ability to generate ClO₂ on-site reduces the risks associated with transporting and storing hazardous chemicals.

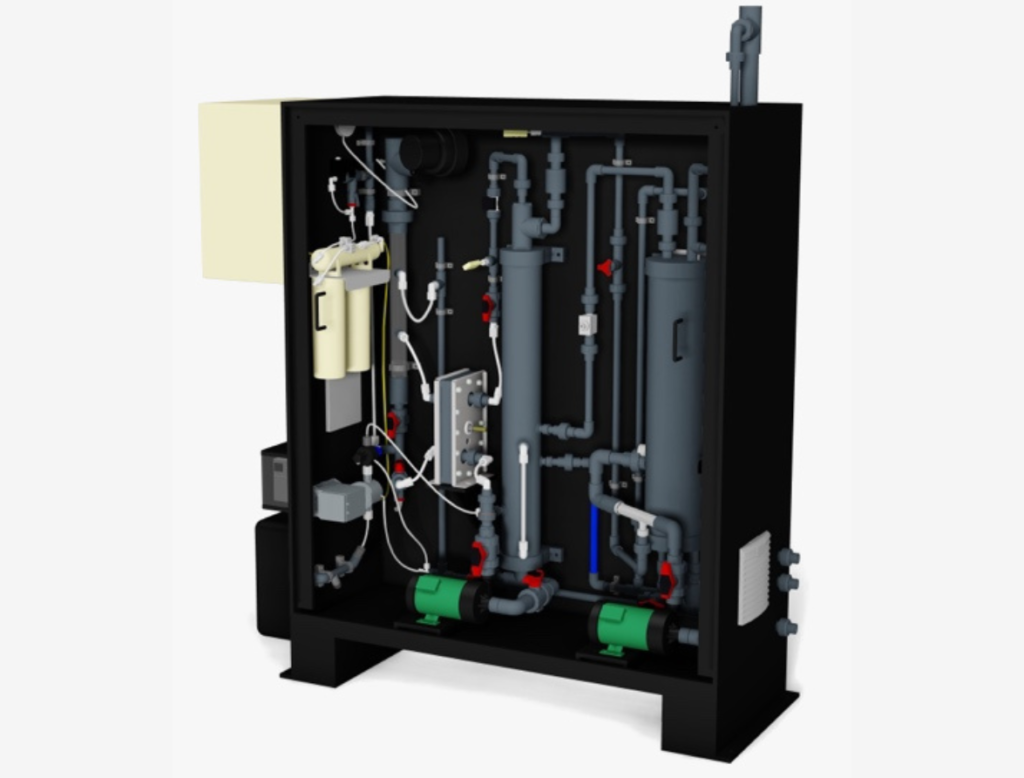

EAI Water’s Chlorine Dioxide Generators

EAI Water offers state-of-the-art electrochemical, single-chem chlorine dioxide generators that leverage advanced technology to provide reliable and efficient disinfection solutions. Our generators are designed to meet the needs of various industries, from municipal water treatment to large-scale industrial application to healthcare secondary disinfection. Key features of our generators include:

- High Conversion Efficiency: Maximizes chlorine dioxide production with minimal waste.

- Safety-First Design: Incorporates advanced safety features to protect personnel and the environment.

- Operational Flexibility: Scalable solutions that can be tailored to specific application requirements.

Practical Considerations for Chlorine Dioxide Generation

When implementing a chlorine dioxide generation system, several practical considerations must be taken into account to ensure optimal performance and safety:

- System Design: The design of the chlorine dioxide generation system should align with the specific needs of the application. Factors such as the required dosage, flow rate, and water quality should be carefully evaluated to determine the appropriate system size and configuration.

- Safety Protocols: Safety is paramount when dealing with any chemical generation system. Ensuring that proper ventilation, spill containment, and emergency shutdown systems are in place is critical to protecting both personnel and the environment. EAI Water’s systems are equipped with advanced safety features that minimize risks and ensure compliance with stringent safety regulations.

- Maintenance and Monitoring: Regular maintenance of the generation system is essential to ensure consistent performance. This includes routine inspections, calibration of dosing equipment, and replacement of worn components. Additionally, real-time monitoring of chlorine dioxide levels in the treated water helps to maintain optimal disinfection efficacy. EAI Water provides comprehensive maintenance and monitoring services to ensure your system operates at peak performance.

- Regulatory Compliance: Staying informed about local and national regulations regarding the use of chlorine dioxide in water treatment is essential. Ensuring compliance not only protects public health but also helps avoid potential legal issues. EAI Water’s experts can assist in navigating these regulations, ensuring that your facility meets all necessary standards.

Case Study: EAI Water’s Impact

Overview: A large-scale industrial food production facility faced challenges with byproduct management and compliance with stringent water treatment regulations. The facility needed a reliable and efficient solution to produce chlorine dioxide on-site.

Solution: EAI Water installed a state-of-the-art electrochemical chlorine dioxide generator that provided high-purity ClO₂ with minimal to no chlorate residual. The system was integrated seamlessly into the facility’s existing infrastructure, ensuring operational continuity.

Results: The facility saw a 30% reduction in chemical consumption, a 50% decrease in harmful byproducts, and full compliance with all regulatory requirements. The switch to on-site chlorine dioxide generation also reduced the facility’s carbon footprint by eliminating the need for chemical transportation.

Frequently Asked Questions (FAQ)

Q: Why consider on-site chlorine dioxide generation?

A: On-site generation provides greater control over chlorine dioxide production, reduces transportation risks, and minimizes environmental impact.

Q: Where can chlorine dioxide generators be used?

A: Chlorine dioxide generators are versatile and can be used in a variety of settings, including municipal water treatment plants, industrial facilities, cooling towers, and food processing plants.

Q: What makes a good chlorine dioxide generator?

A: A good generator should offer high conversion efficiency, safety features, scalability, and ease of integration into existing systems. EAI Water’s generators are designed to meet these criteria, providing reliable and efficient disinfection solutions.

Contact Us

For more information about EAI Water’s chlorine dioxide generation technology, or to request a product brochure, please contact us. Our team of experts is ready to assist you in finding the right solution for your specific water treatment needs.