Chlorine Generation in Industrial Settings: Applications and Benefits

At EAI Water, we focus on sustainable, people-driven water management across the western United States. Our expertise in disinfectant technologies helps clients meet regulatory requirements, protect critical systems, and reduce waste. Whether it’s optimizing a cooling tower or ensuring safe potable water, we’ve seen how chlorine generation can offer meaningful advantages.

Disinfection is a critical part of any industrial water treatment program, but how it’s delivered can impact safety, performance, and cost. Chlorine has long been trusted for its effectiveness (both in solution and chlorine gas), but today, more facilities are turning to on-site chlorine generation as a smarter, safer alternative to traditional bulk delivery.

On-site chlorine generation allows facilities to produce chlorine as needed, using just salt, water, and electricity. The result is a more stable and consistent disinfectant with fewer storage concerns and reduced risk to personnel.

What is Chlorine Generation?

Chlorine generation refers to the on-site production of chlorine-based disinfectant, typically in the form sodium hypochlorite (NaOCl), using a process called electrolysis. Instead of relying on bulk deliveries of pre-manufactured bleach or hazardous chlorine gas from various parts of the US, facilities generate their own chlorine solution or chlorine gas as needed, using just a single precursor.

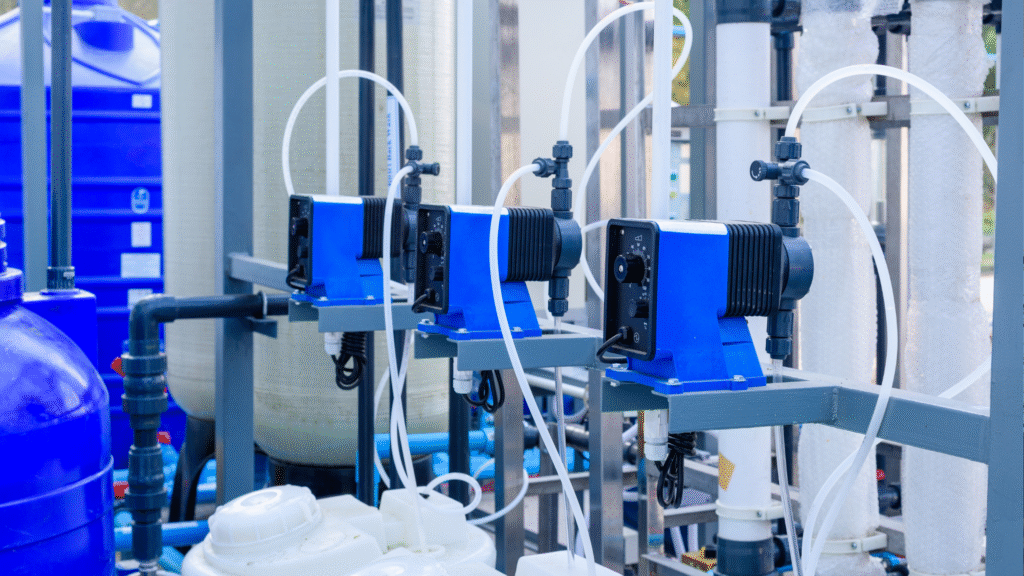

The core technology behind chlorine generation is surprisingly straightforward. A brine solution (salt and water) passes through an electrolytic cell, where a direct electrical current splits the salt molecules. The result is a low-concentration sodium hypochlorite solution, typically around 7% available chlorine—safer to handle and more stable than commercial bleach.

This process is not only cleaner but also offers greater control over dosing and storage. On-site systems are modular and scalable, making them a fit for everything from small commercial buildings to large industrial plants with demanding water treatment process.

Chlorine Benefits in Industrial Applications

Chlorine’s broad-spectrum disinfection capabilities make it a cornerstone in industrial water treatment. Sodium hypochlorite quickly neutralizes bacteria, viruses, and algae, reducing the risk of microbial fouling, equipment damage, and health code violations. This technology is widely used in industries ranging from agriculture to healthcare and is gaining momentum as a safer, more sustainable approach to drinking water chlorination in both commercial and municipal settings.

Systems such as potable water lines and cooling towers benefit from sodium hypochlorite’s ability to maintain a measurable residual, which continues to suppress microbial growth downstream. Chlorine’s compatibility with common materials of construction and chemical formulations adds to its utility, ensuring it performs reliably in diverse process environments.

Applications Across Industries

Chlorine generation plays a critical role in a variety of industrial and commercial settings. Its flexibility and reliability make it a go-to solution for facilities that require consistent, on-demand disinfection without the added risks of storing or transporting hazardous chemicals.

1. Water and Wastewater Treatment

Municipal and industrial water treatment plants rely on chlorine solution (typically in the form of sodium hypochlorite) to meet regulatory standards for disinfection and public health. On-site chlorine generation offers operators greater control over dosing, reduces the need for hazardous chemical deliveries, and supports compliance with strict environmental and safety regulations.

2. Cooling Tower Systems

In cooling towers, microbial growth can lead to biofilm formation, scaling, and corrosion—threatening system performance and increasing maintenance costs. Dosing sodium hypochlorite helps control biological activity, and chlorine generation ensures a fresh, stable disinfectant that can be precisely dosed to meet system demand. This helps extend equipment life and improves heat transfer efficiency.

3. Food and Beverage Processing

Facilities in the food and beverage industry require strict microbial control in both process water and sanitation systems. On-site chlorine generation supports consistent disinfection, reduces contamination risk, and eliminates the need to store high-concentration chemicals near production areas.

4. Chemical Manufacturing

Chemical production processes often require disinfected water for cooling, rinsing, or as a component in formulation. Generating sodium hypochlorite or chlorine on-site ensures a consistent supply while minimizing supply chain disruptions and chemical handling concerns.

5. Agriculture and Irrigation

In agriculture, water quality has a direct impact on crop yield and soil health. On-site sodium hypochlorite generation helps control pathogens in irrigation systems and livestock operations, supporting healthier growing conditions and reducing the risk of disease spread.

Supporting Drinking Water Safety

On-site chlorine generation supports safe, effective drinking water chlorination by producing a fresh, low-concentration disinfectant that meets EPA residual standards. This is especially useful in healthcare facilities, schools, and residential buildings, where maintaining public health and regulatory compliance with drinking water supplies is critical.

Advantages of On-Site Chlorine Generation

Switching from delivered chlorine to on-site generation offers a range of practical benefits that improve safety, reduce costs, and streamline operations. For facilities looking to modernize their water treatment approach, these advantages can make a meaningful difference in day-to-day performance and long-term planning.

Improved Safety

By generating a diluted hypochlorite solution, on-site systems dramatically reduce chemical severity. This lowers the likelihood of exposure incidents, simplifies emergency planning, and removes many of the risks associated with gas cylinders (through production of chlorine gas) or high-strength chlorine bleach (through production of chlorine solution). It also limits the need for specialized storage, ventilation systems, and complex handling protocols.

Operational Control

With chlorine produced directly on-site, facilities are no longer dependent on chemical deliveries or third-party supply chains. This improves reliability during times of supply disruption and allows for real-time adjustments in dosing based on system demand. Operators maintain tighter control over water quality without the uncertainty of outside sourcing, minimizing the need to remove chlorine from a process water.

Cost Efficiency

While the upfront investment in a chlorine generator can be significant, the long-term savings are substantial. Facilities eliminate recurring transportation and delivery fees, reduce chemical loss from degradation, and minimize labor associated with handling and storage. Many operations see a return on investment in just a few years.

Environmental Benefits

Generating chlorine on demand supports sustainability goals by cutting down on the carbon footprint associated with transporting bulk chemical compounds. It also reduces plastic and packaging waste and the need for onsite storage tanks. The use of salt, water, and electricity as inputs makes the process more environmentally responsible, especially when paired with renewable energy sources.

Chlorine Generation and Regulatory Compliance

Regulatory compliance is a major concern in any industrial water treatment program, and disinfection practices are often at the center of that conversation. On-site chlorine or chlorine dioxide generation simplifies compliance by reducing chemical hazards and aligning with key safety and environmental standards.

One of the most significant advantages is the reduction in high-risk chemical storage. Traditional pure chlorine gas and high-concentration hypochlorite solutions are classified as hazardous materials, requiring strict adherence to OSHA Process Safety Management (PSM) standards, EPA Risk Management Plans (RMP), and local fire codes. On-site systems, which can be tailored to produce a specific chemical concentration, often fall outside these thresholds, easing the compliance burden.

In potable water and cooling systems, maintaining a chlorine residual is critical for controlling microbial growth, including Legionella. Chlorine generation and chlorine dioxide generation provides consistent dosing, making it easier to meet health codes and public safety requirements (ie. safe drinking water). Many systems also integrate automated monitoring, helping facilities stay within regulatory limits without manual adjustments and ensuring fewer disinfection byproducts.

By eliminating bulk chemical deliveries and excess chlorine, on-site generation also minimizes the risk of spills, leaks, and transportation-related incidents—each of which can trigger compliance violations or reporting requirements. This makes it a practical choice for facilities that need to meet high safety standards without adding administrative overhead.

Chlorine vs. Chlorine Dioxide Generation: What’s the Difference?

Though often grouped together under the label of chemical disinfection, chlorine and chlorine dioxide function very differently—and understanding those differences is key to choosing the right solution for your water treatment program.

Chlorine (usually in the form of sodium hypochlorite) is a strong oxidizer that’s widely used for secondary disinfection, microbial control in cooling towers, and general-purpose water treatment. It’s most effective at lower pH levels and leaves a measurable residual, making it ideal for systems that require ongoing microbial suppression, such as potable water lines and industrial loops.

Chlorine dioxide, by contrast, is not a chlorinating agent. It works through oxidation rather than substitution, making it more effective against biofilms and chlorine-resistant organisms like Giardia and Cryptosporidium. It maintains efficacy across a broader pH range (typically 5–9), and it doesn’t form regulated by-products like trihalomethanes (THMs) or chloramines. That makes it a preferred option for high-risk or sensitive applications—like food processing, healthcare facilities, and water systems with organic loading.

Both disinfectants are generated on-site:

- Chlorine is produced via electrolysis of salt (brine), forming a low-concentration hypochlorite solution.

- Chlorine dioxide can be produced through traditional two-chemical systems or newer single-precursor electrochemical generators.

Choosing between the two depends on several factors: water quality, regulatory limits, disinfection goals, and system constraints. In some cases, the technologies are even used together, with chlorine dioxide serving as a primary disinfectant and chlorine maintaining residual downstream.

How EAI Supports On-Site Generation Systems

Designing and integrating an on-site chlorine or chlorine dioxide generation system is about building the right solution around your facility’s disinfection needs, safety priorities, and compliance requirements. At EAI, we bring decades of experience in water treatment system design, installation, and long-term support for both electrochemical chlorine generators and chlorine dioxide generators.

Our team works closely with industrial, commercial, and institutional facilities to determine the best-fit technology for their application. Whether replacing hazardous gas chlorination, upgrading from bulk bleach, or designing a system from the ground up, we assess water chemistry, flow rates, risk factors, and regulatory requirements to size and spec each system correctly.

EAI manufactures and supports a full line of on-site generation systems, including:

- HG Series Electrochemical Chlorine Generators for safe, low-cost production of sodium hypochlorite or pure chlorine gas from just salt and water

- Electricide® Single-Chem Chlorine Dioxide Systems for high-purity ClO₂ generation without the need for acid handling or complex chemical storage

After installation, we provide hands-on commissioning, automation integration, remote monitoring setup, and operator training. We also offer ongoing support to fine-tune dosing, ensure chlorine residual compliance, and troubleshoot performance changes so your system stays optimized without burdening your staff.

For facilities focused on safety, uptime, and long-term sustainability, EAI’s generator systems offer a proven path forward. We help you transition away from risky, outdated chemical delivery models and toward smarter, more resilient disinfection strategies, backed by equipment we design and service ourselves.

Ready to Rethink Your Chlorine Strategy?

Chlorine generation is more than a trend – it’s a smarter way to meet today’s disinfection demands while preparing for tomorrow’s operational challenges. Whether you’re aiming to reduce risk, cut costs, or meet tighter regulations, this technology offers a practical path forward.

If you’re considering onsite chlorine generation for your facility or drinking water needs, EAI is here to help you evaluate the options and find the best-fit solution. Our team brings deep technical knowledge and hands-on experience to every project, with a focus on sustainable water management that works in the real world.

Let’s talk about how chlorine generation could fit into your water treatment plan.

Frequently Asked Questions (FAQs)

Q: What are the main benefits of chlorine generation compared to traditional chlorine delivery?

A: On-site generation improves safety by reducing the need for high-concentration chemicals, lowers long-term costs, and provides a consistent, freshly produced disinfectant with minimal degradation.

Q: Is on-site chlorine generation safe?

A: Absolutely. On-site systems generate a mild disinfectant solution, usually under 1% chlorine concentration, which significantly reduces handling risk. This eliminates the hazards associated with high-pressure gas tanks or concentrated bleach drums, making operations safer for personnel and easier to manage under most safety regulations.

Q: Does chlorine generation require a lot of maintenance?

A: Most systems are designed for low maintenance and can be monitored remotely. Routine cleaning of the electrolytic cell and regular system checks are usually sufficient to keep performance on track.

Q: What kind of facilities benefit most from on-site chlorine generation?

A: Cooling towers, potable water systems, wastewater treatment plants, food and beverage facilities, and agricultural operations all benefit—especially those looking to improve reliability, reduce chemical handling, or meet sustainability goals.

Q: How do I know if chlorine generation is right for my system?

A: Factors like water demand, existing disinfection methods, safety goals, and regulatory requirements all play a role. A water treatment specialist can evaluate your system and help you determine whether it’s a good fit.