Biofilm Control in Food & Beverage Process Water Systems

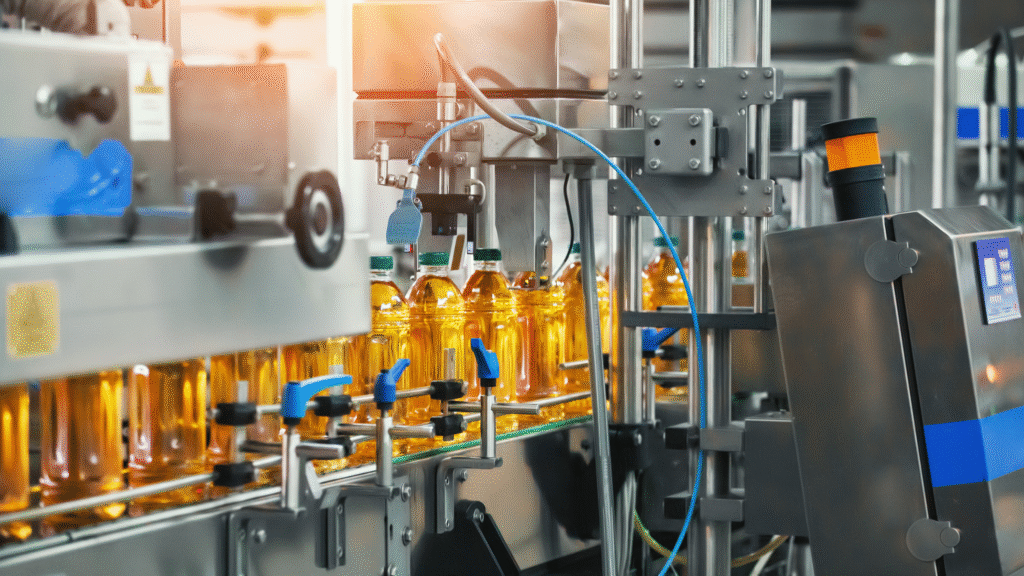

When it comes to maintaining food safety and operational reliability, many food and beverage facilities focus on obvious threats. This includes raw material contamination, equipment failure, or microbial risks in finished product lines. But there’s a less visible, more persistent problem quietly compromising cooling loops, heat exchangers, and process water systems known to promote biofilm formation and growth.

Biofilms are complex microbial communities that attach to surfaces and form protective layers of extracellular polymeric substances (EPS). Once established in pipes, tanks, or heat exchangers, they’re notoriously difficult to remove, and even harder to keep from returning due to their enhanced resistance. For facilities producing beverages, dairy, or packaged foods, these hidden contaminants can lead to microbial violations, poor heat transfer, and escalating energy and chemical costs.

At EAI, we’ve seen firsthand how biofilm outbreaks disrupt both production and compliance. As part of our “The Water Industry is All Industry” campaign for food & beverage industry, we will explore how biofilm develops in industrial water systems and more importantly, how proactive water treatment help in controlling biofilm formation before it compromises quality or safety.

Why Biofilm Is a Hidden Threat to Food & Beverage Facilities

Biofilms are more than just microbial buildup. They’re resilient, structured communities of bacteria, fungi, and other microorganisms that form on moist surfaces and evolve over time. These communities are encased in a sticky, self-produced EPS matrix that protects them from various elements like heat, disinfectants, and even aggressive chemical cleaning agents.

According to the U.S. Environmental Protection Agency (EPA), biofilms form when bacteria attach to environmental surfaces in the presence of moisture, where they reproduce and colonize, often becoming invisible threats to food production systems. Once established, they thrive in areas like piping, packaging lines, heat exchangers, and food-contact surfaces even in quick-service restaurants (QSRs) and full-service kitchens, often exacerbated by human activities .

What makes them so dangerous is how they adapt. Through changes in gene expression, cell morphology, and metabolic behavior, microorganisms within biofilms can resist chemical treatments and shed planktonic cells, which travel downstream and colonize new bacterial surfaces. The result? Persistent microbial contamination, biofilm-related infections, and product integrity issues that aren’t always easy to trace back to the source.

The Consequences Go Beyond Hygiene:

- Heat Transfer Inefficiencies: In cooling systems and heat exchangers, biofilm buildup acts as a thermal insulator, reducing heat transfer efficiency and increasing engine heat. Even a thin layer can spike energy consumption and strain equipment.

- Cross-Contamination and Spoilage: Biofilms can harbor pathogens like Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus, and Listeria monocytogenes. These microbes, including resilient aureus biofilms can break off and enter process streams, rinse water, or clean-in-place (CIP) systems, leading to contamination and spoilage.

- Reduced Shelf Life and Increased Waste: Often, biofilms degrade product quality before visible signs appear. This results in shortening shelf life, increasing food waste, and reducing consumer satisfaction without a clear cause.

- Regulatory Risks and Audit Failures: Persistent biofilm colonies can push microbial levels beyond safety thresholds and result in violations during FDA, USDA, or third-party inspections. And because they resist many antibiotic treatments, they pose a long-term compliance risk.

- Economic and Operational Losses: A cheese manufacturing plant eradicating biofilm-related inefficiencies can lead to a $7.6 million increase in annual output and a savings of 2.4 million gallons of water. Similar improvements are possible in breweries, carbonated beverage lines, higher education, and dairy production.

How Biofilm Forms in Cooling and Process Water Systems

Biofilm development isn’t an overnight event. It’s a multi-stage process that begins at the microscopic level and, if left unchecked, can quickly impact the entire cooling system. In food and beverage processing environments, the constant presence of liquid, moisture, organic matter, and favorable temperatures creates ideal conditions for biofilm growth.

Let’s break down the biofilm formation process in cooling systems and process water lines:

1. Initial Attachment

Free-floating, or planktonic, bacterial cells in the water begin to adhere to surfaces like pipes, heat exchangers, and cooling tower fill. These surfaces are often made of metal, PVC, or other materials with microscopic imperfections that make ideal footholds.

2. Irreversible Attachment

Within hours, the bacterial cells begin producing EPS substances —a sticky biofilm matrix that acts like glue. This anchors the cells permanently and begins forming a protective layer in a cooling system.

3. EPS Matrix Maturation

As more bacterial appendages join the colony, the biofilm thickens. The EPS matrix helps shield the microbial community from disinfection chemicals, heat, and even shear forces from flowing water.

4. Mature Biofilm

At this stage, the biofilm becomes highly resistant. It harbors a variety of microbial communities including pathogenic strains like aeruginosa biofilms capable of surviving harsh conditions and regenerating after cleaning attempts.

5. Dispersion

Under stress or nutrient scarcity, parts of the biofilm release planktonic cells into the cooling system. These cells travel downstream to colonize new surfaces, repeating the cycle, which can be mitigated by various strategies .

In cooling towers and closed-loop systems, biofilm formation often begins on heat exchanger surfaces where temperature fluctuations and surface roughness promote early attachment. In process water systems, biofilms tend to develop at low-flow zones, bends, and dead legs.

Importantly, studies show that biofilm biomass can reduce heat transfer efficiency by more than 30% and promote corrosion beneath the EPS layer. This ultimately makes proactive biofilm control a critical part of cooling system maintenance.

Risks of Uncontrolled Biofilm Growth in Food & Beverage Plants

In the food and beverage industry, water is part of the production environment. That means biofilm isn’t just a maintenance issue; it’s a food safety risk. When left unchecked, biofilm growth in cooling systems and process water lines can compromise both operational reliability and regulatory compliance.

Here’s what’s at stake:

1. Contamination of Product Contact Surfaces

Biofilms can spread from cooling water or non-contact areas into processing equipment, especially through poorly maintained CIP (clean-in-place) systems or shared utilities. Bacterial fragments or endotoxins can break loose and contaminate surfaces where food is processed or packaged.

- Mixed-species biofilms, such as aeruginosa or enterococcus faecalis, are often resistant to standard cleaning and can colonize hard-to-reach internal surfaces.

2. Reduced Heat Transfer Efficiency

A mature biofilm acts as a thermal insulator. As it thickens on heat exchangers, chillers, or evaporative condensers, it impairs the system’s ability to transfer heat effectively. This forces equipment to work harder, increasing energy consumption and reducing overall process efficiency.

- In cooling towers, a thin biofilm layer just 0.5 mm thick can cause up to a 15% reduction in heat transfer performance.

3. Accelerated Corrosion and Equipment Damage

Bacteria in biofilms excrete acids and generate localized low-oxygen environments, accelerating under-deposit corrosion. This weakens metal surfaces from the inside out, leading to unplanned shutdowns, costly repairs, or even full system replacements.

- Other components like valves, pumps, and stainless steel piping are especially susceptible in the presence of biofilm matrix corrosion agents.

4. Regulatory Non-Compliance

Regulators increasingly recognize biofilm as a contributor to microbial contamination events. Failure to control biofilm in cooling or process water systems may trigger citations during inspections or product recalls if contamination spreads.

- Biofilm-related issues can also violate FDA, USDA, and state-level environmental codes—especially when cooling water is reused or crosses into process streams.

5. Public Health and Brand Reputation

Biofilms can harbor pathogens like Escherichia coli, Staphylococcus aureus, or Pseudomonas aeruginosa, which can lead to biofilm related infections and illness if they contaminate food products. Even a single outbreak tied to poor water system hygiene can have serious clinical applications resulting in massive brand damage and legal liability.

Strategies to Prevent and Control Biofilm in Industrial Water Systems

Effective biofilm control requires a comprehensive, proactive approach and not just periodic chemical treatment. In industrial cooling and process water systems, especially in food and beverage plants, prevention must be built into every level of the system’s design, operation, and maintenance.

Here are the most effective strategies used to prevent and control biofilm growth:

1. Maintain Proper Flow and Temperature Control

Biofilm thrives in stagnant or low-flow zones. Ensure that all parts of your water system maintain consistent circulation, especially in remote or seasonal areas of your plant.

- Keep temperatures outside the bacterial growth “comfort zone” (77–113°F or 25–45°C) where possible.

- Design for turbulence, not laminar flow, to disrupt early stages of irreversible attachment.

2. Use Biocides and Dispersants Strategically

A well-formulated water treatment program that includes both oxidizing and non-oxidizing biocides can disrupt biofilm structure and kill embedded microbial communities. Dispersants help loosen and remove extracellular polymeric substances (EPS) that protect bacteria.

To combat highly resistant biofilms, food and beverage facilities are increasingly adopting advanced disinfection technologies. One such solution includes peracetic acid-based (PAA) disinfectants—EPA-registered antimicrobials capable of eliminating up to 99.9999% of pathogens, including Pseudomonas aeruginosa, Listeria monocytogenes, and biofilm biomass on hard, nonporous surfaces.

These treatments are powerful because they:

- Destroy biofilms at the source rather than simply suppressing surface contamination.

- Require no rinsing, which conserves water and streamlines sanitation protocols.

- Improve worker safety and air quality, especially in enclosed food production areas.

- Support sustainability initiatives, making them ideal for facilities aiming to reduce chemical footprint.

When used in combination with dispersants and targeted cleaning, PAA-based products offer a scalable, rinse-free solution that enhances both microbial control and environmental stewardship. Alternating or rotating biocides especially when combining oxidizers, antimicrobial peptides, and dispersants also prevents bacteria from developing resistance through quorum sensing mechanisms.

3. Conduct Routine Microbiological Testing

Testing for biofilm indicators like heterotrophic plate counts (HPC), ATP, or total organic carbon (TOC) can identify biofilm hotspots before visible problems emerge.

4. Regular Mechanical Cleaning

Even with chemical treatments, some systems require mechanical or physical cleaning to eliminate biofilm biomass from surfaces. This includes:

- Scrubbing or pigging of piping systems

- Plate-and-frame heat exchanger disassembly and cleaning

- Scheduled tower basin cleaning

5. Surface Treatments and Equipment Design

Where possible, select materials and coatings that reduce microbial adhesion and biofilm development, especially in cooling systems and heat exchangers.

- Surfaces like polished stainless steel reduce bacterial cell wall adhesion.

- Avoid dead legs and low-flow zones in pipe design, which promote initial attachment and EPS production.

6. Leverage Automation and Real-Time Monitoring

Online monitoring systems that track biofilm risk parameters such as pH, conductivity, ORP, or biocide residuals help teams intervene quickly when conditions favor microbial growth.

How EAI Helps the Food and Beverage Industry Control Biofilm

At EAI, we bring decades of experience in managing complex water systems across industries with high cleanliness and compliance demands — none more critical than food and beverage production. Our tailored approach to biofilm control blends field expertise, advanced equipment, and proactive monitoring to protect process water and cooling systems from microbial contamination.

Customized Biofilm Control Programs

We design site-specific water treatment programs for food and beverage facilities, including those with seasonally variable operations or high water quality demands. Our programs integrate:

- Low-dose chemical treatments prevent biofilm formation without compromising product integrity or safety. These include custom-formulated dispersants, corrosion and scale inhibitors, pH balancers, detergents, and biocides engineered to deliver maximum cycles of concentration while reducing overall chemical use and environmental impact. Our formulations are designed to hold sparingly soluble salts well beyond saturation, helping minimize blowdown and water waste while effectively killing microbiological threats and removing biofilms.

- Industry-leading dosing technology, such as the Dober Smart Release® system, enables precise, cost-effective delivery of actives that support consistent biofilm eradication in cooling towers and process loops.

- Alternating oxidizing and non-oxidizing biocides to disrupt microbial resistance

- Biofilm dispersants to break down the EPS matrix and release embedded bacterial colonies before they mature into resistant biofilms.

Whether you operate a dairy, brewery, or processing plant, our strategies ensure that cooling towers, heat exchangers, and recirculation loops remain biofilm-free and compliant with industry hygiene standards.

Total Water Systems and Reuse Solutions

EAI offers custom-built water reuse and recycling systems that minimize water consumption while maintaining microbiological safety. In food and beverage applications, we adapt these technologies to suit high-risk environments:

- Prefiltration and reverse osmosis to remove suspended solids and biofilm-related contaminants

- Chlorine dioxide generators for disinfection in food-safe process water

- UV sterilization and nanofiltration where chemical-free treatment is required

- DI exchange tanks for high-purity water in sensitive production zones

These solutions are critical in reducing biofilm risk at every point of your system—from ingredient water to CIP (clean-in-place) loops.

Integrated Monitoring and Compliance Support

With EAI, your team gains more than just equipment and chemicals—you gain a long-term partner in system performance. We provide:

- On-site microbiological testing to identify early-stage biofilm development

- Digital documentation and compliance tracking to support food safety audits and inspections

- Single-source accountability so plant operators and QA teams can focus on production—not troubleshooting water issues

Our specialists monitor each treatment application across your site, ensuring that water systems operate safely, efficiently, and with full regulatory confidence.

Learn more about EAI’s water treatment programs for the hospitality sector and custom cooling tower chemical solutions tailored to industry-specific risks.

Sustaining Operational Integrity Through Biofilm Control

In the food and beverage industry, biofilm control is also about brand protection, regulatory compliance, and the safety of your end product. Left unmanaged, microbial communities can quietly compromise cooling systems, heat exchangers, and process water loops, leading to production downtime, contamination risks, and premature equipment failure.

Whether you need continuous monitoring, specialty disinfection, or engineered reuse systems that support sustainability goals, we deliver proven solutions that keep your systems running clean. Contact EAI today to take control of biofilm risk in your cooling systems and process water loops. Because in your industry, clean water means clean production.