Beverage Quality Control: Optimizing Water with Chlorine Dioxide

Water is considered as the backbone of nearly every beverage product, from bottled soft drinks and alcoholic beverages to functional waters and ready-to-drink teas. It influences everything from product taste and aroma to shelf life and consumer safety. For beverage producers aiming to deliver a high quality product, managing water quality is one of the most critical steps in quality control.

As beverage production systems grow more complex and consumer expectations rise, ensuring water consistency across production runs has become an essential part of maintaining brand reputation. Any variation in water chemistry (microbial load, mineral content, or residual disinfectants) can introduce quality issues that compromise flavor, appearance, or safety. That is why water treatment is no longer a background utility. It is a strategic component of beverage quality control that requires careful monitoring, rigorous testing, and optimization.

This article explores how chlorine dioxide plays a key role in optimizing water for beverage production. From microbial safety to sensory consistency, chlorine dioxide helps facilities meet specific standards for quality, safety, and efficiency while protecting the final product from contamination risks.

Why Beverage Quality Control Starts with Water

Water may seem like a simple ingredient, but in beverage testing and production, it directly shapes the chemical, sensory, and physical characteristics of the final product. The quality plays a defining role to ensure consistency in product standard across batches.

Raw water sources often contain dissolved minerals, organic compounds, or microbial contaminants that can interfere with flavor, pH, color, and shelf life. Even trace variations in elements like calcium, magnesium, chlorine, or sulfate can cause shifts in beverage taste, mouthfeel, and clarity. These inconsistencies may not be noticeable to the casual consumer at first, but over time, they erode customer satisfaction and weaken a brand’s ability to deliver a high quality beverage with each production run.

From a quality assurance standpoint, untreated or poorly treated water introduces risk across multiple areas. It may lead to off-flavors, spoilage, reduced carbonation stability, or unwanted sedimentation. For alcoholic beverages, poor water quality can affect specific gravity, alcohol content, and fermentation kinetics. For functional drinks or juices, it can reduce nutritional stability and speed up microbial growth.

Critical Control Points in Beverage Production

Identifying and managing critical control points (CCPs) is essential for preventing contamination, ensuring safety, and maintaining product quality. CCPs are specific stages in the production process where a loss of control could result in a significant safety risk or quality defect. When water is used at these points (whether for mixing, cleaning, or bottling) it must be properly treated and consistently monitored.

Common CCPs in beverage facilities include blending tanks, rinse water stations, clean-in-place (CIP) systems, and packaging lines. These areas are highly vulnerable to microbial intrusion or chemical residues if water quality is not rigorously controlled. For example, inadequate disinfection in rinse water can introduce pathogens that compromise the shelf life and safety of the final product. Likewise, residual chlorine or minerals in mixing water may interfere with flavor balance and sensory performance.

Hazard analysis programs help facilities pinpoint where these risks are most likely to occur. Once identified, corrective actions such as upgrading filtration, enhancing disinfection protocols, or incorporating continuous water monitoring can be implemented. Chlorine dioxide is particularly well suited for this role, offering strong antimicrobial action with minimal impact on taste or aroma. When applied at key CCPs, it helps ensure water contributes to the safety and consistency of beverage products.

Read more from our blog: Clean in Place: CIP Systems in Food & Beverage

Benefits of Chlorine Dioxide in Beverage Water Treatment

Chlorine dioxide is widely recognized in the beverage industry for its ability to provide effective disinfection without compromising product quality. Compared to traditional chlorine, it offers a cleaner, more controlled treatment process that aligns with food and beverage safety standards.

Here are some of the key benefits of using chlorine dioxide in beverage water treatment:

- Broad-spectrum antimicrobial efficacy: Effective against bacteria, viruses, molds, and biofilms that can form in piping, tanks, or rinse lines.

- Stable performance across pH levels: Maintains disinfecting power in a wide pH range, making it versatile for different beverage processes.

- Minimal impact on taste and aroma: Unlike chlorine, chlorine dioxide does not produce strong odors or off-flavors, preserving the intended sensory profile.

- Low formation of harmful by-products: Produces fewer regulated disinfection by-products such as trihalomethanes (THMs) or haloacetic acids (HAAs).

- Compatible with system materials: Works well with stainless steel and modern beverage processing equipment, reducing corrosion concerns.

- Supports consistent product quality: Reduces microbial and chemical variability in the water, helping maintain uniformity across production runs.

- Enhances safety and compliance: Helps meet strict regulatory standards for microbial control and residual disinfectants.

For beverage producers prioritizing safety, reliability, and consistent taste, chlorine dioxide provides a smart and proven water treatment strategy.

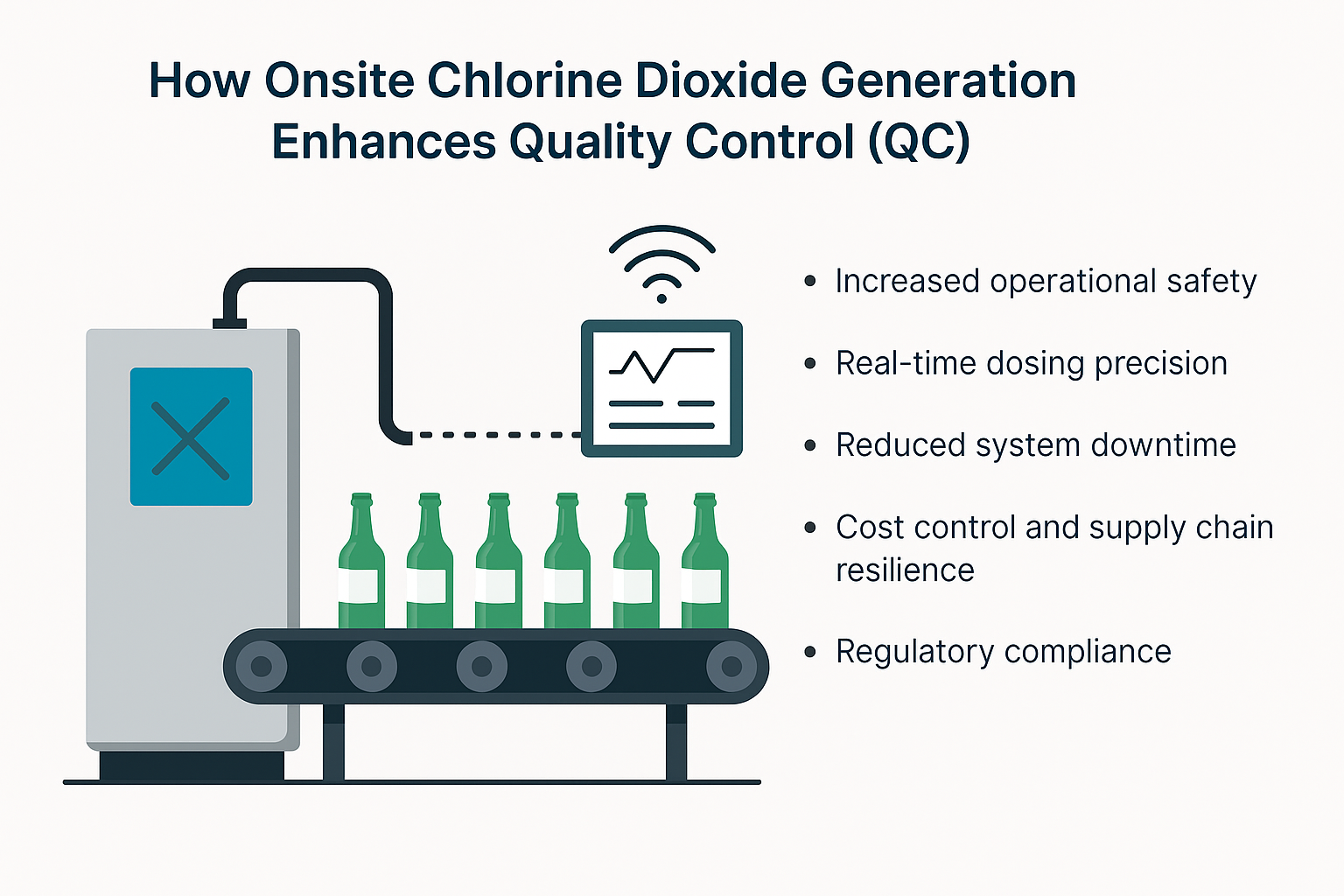

How Onsite Chlorine Dioxide Generation Enhances Quality Control (QC)

Many beverage producers are moving toward onsite chlorine dioxide generation to gain tighter control over their water treatment process and improve overall cost efficiency. This approach not only ensures a consistent disinfectant supply but also eliminates the risks associated with storing and handling bulk chemicals.

EAI’s chlorine dioxide systems, built in collaboration with Dioxide Pacific, use a single chemical precursor to generate high-purity chlorine dioxide onsite. This generation method reduces complexity, minimizes by-product formation, and allows beverage facilities to inject disinfectant precisely where and when it is needed. These systems are equipped with remote monitoring capabilities and safety interlocks to ensure reliable operation during continuous production runs.

The benefits of onsite chlorine dioxide generation for beverage quality control include:

- Increased operational safety: Eliminates the need for transporting and storing hazardous chlorine-based chemicals.

- Real-time dosing precision: Ensures the correct amount of disinfectant is used at critical control points, helping prevent microbial contamination.

- Reduced system downtime: On-demand generation supports continuous improvement in production without waiting for chemical deliveries or manual mixing.

- Cost control and supply chain resilience: In-house generation protects against market volatility and delays in chemical testing and procurement.

- Regulatory compliance: Produces disinfectant to the purity standards required for beverage production and food-contact applications.

By integrating chlorine dioxide generation into their operations, beverage companies gain greater assurance that water quality supports rather than threatens the consistency, safety, and reputation of their products.

Real-World Example: Chlorine Dioxide in Clean-In-Place (CIP) Systems

Chlorine dioxide has become a preferred disinfectant in CIP applications due to its efficiency and minimal impact on processing equipment. It effectively removes biofilm and kills microorganisms at low concentrations, without leaving residual taste or odor that could affect the next batch. Unlike chlorine, it is less corrosive to stainless steel and other raw materials commonly used in beverage facilities.

When integrated into CIP protocols, chlorine dioxide helps protect the finished product, maintain packaging integrity, and support the production of high quality beverages with fewer cleaning cycles and shorter system downtime. By controlling microbial risk without compromising production efficiency, it plays a direct role in quality assurance and operational success.

Read more on our blog: Clean in Place: CIP Systems in Food & Beverage

Case Study: Supporting a National Bottled Water Brand with Flexible CIP Design

EAI partnered with a leading canned and bottled rainwater brand committed to exceeding industry standards while minimizing environmental impact. The client needed a scalable, mobile water treatment solution that could ensure microbial safety and meet strict FDA regulations on residual disinfectants without relying on chlorine.

EAI designed a modular treatment system that included multimedia filtration, PFAS-targeted filters, UV disinfection, and an ozone-based CIP system. The system was housed in a 15-foot container, enabling deployment across three U.S. collection sites with plans for rapid expansion. To streamline CIP operations, EAI integrated remote monitoring, automated control valves, and real-time performance tracking to ensure system uptime and product safety.

The clean-in-place design was central to the client’s ability to meet their microbiological standards without using chlorine-based products. By automating sanitation cycles and maintaining clean surfaces across the treatment train, the CIP system (paired with advanced filtration) helped the brand consistently meet non-detect thresholds for harmful contaminants.

Read our full case study: National Bottled Water Brand

Partnering with EAI: Water Quality Programs Tailored for Beverage Companies

Beverage companies operate in a fast-paced environment where product safety, consistent taste, and consumer satisfaction must be maintained without compromise. At EAI, we understand that high-quality beverages start with high-quality water. And delivering this standard requires more than just equipment. It demands a partner who brings technical expertise, long-term planning, and a deep understanding of the beverage industry.

EAI’s proven track record in tailoring water quality programs and proactive monitoring strategies to help the Food Industry meet and exceed their quality control practices. From small batch craft operations to large-scale commercial bottlers, we provide:

- Site-specific chlorine dioxide systems for microbiological testing and risk management

- Pretreatment and Industrial RO designs based on your unique feedwater characteristics

- Remote monitoring and real-time data support for operational transparency

- Regular service and maintenance to support customer expectations and brand reputation

We also help clients address issues related toFood & Beverage Process Water Systems, scaling, and inconsistent chemical analysis that could disrupt beverage production. With a focus on safety, efficiency, and cost control, EAI helps beverage facilities stay ahead of potential hazards and ensure every production run meets exacting standards.

Learn more about our water treatment for Hospitality Industry.

Putting Beverage Quality in Your Control

By integrating robust beverage quality control strategies, including onsite chlorine dioxide generation and reverse osmosis systems, food & drink companies can take proactive steps toward producing safer, more reliable, and better-tasting beverages. With the right partner and the right tools, quality is always within reach.

Contact EAI Water for more details.

Frequently Asked Questions (FAQs)

1. What role does water quality play in addressing safety concerns in beverage production?

Water quality directly affects microbial risk, chemical exposure, and system hygiene. Poor water treatment can lead to contamination of food products and trigger safety concerns that impact consumer health and regulatory compliance.

2. How is polymerase chain reaction (PCR) used in beverage quality control?

PCR is a highly sensitive microbiological testing method used to detect trace levels of pathogens or spoilage organisms in water and finished beverages. It helps ensure microbial safety across various aspects of the production process.

3. What types of food products benefit from chlorine dioxide treatment?

Chlorine dioxide is widely used in beverages as well as other food products that rely on clean processing water, including dairy, juice concentrates, and ready-to-drink formulations. It helps control biofilm and preserve taste without leaving residual odor.

4. Why is raw ingredient protection important in beverage quality control?

Raw ingredients such as sugars, concentrates, or botanicals are highly sensitive to microbial intrusion. Using purified water and effective disinfectants like chlorine dioxide helps prevent contamination early in the process.

5. Where does water treatment fall in the final step of beverage production?

Water treatment plays a role right up to the final step—whether it’s bottle rinsing, CIP sanitization, or dilution. Ensuring clean water during this stage helps maintain packaging integrity and shelf life.