The Role of Filtration in a Healthy Cooling Water System

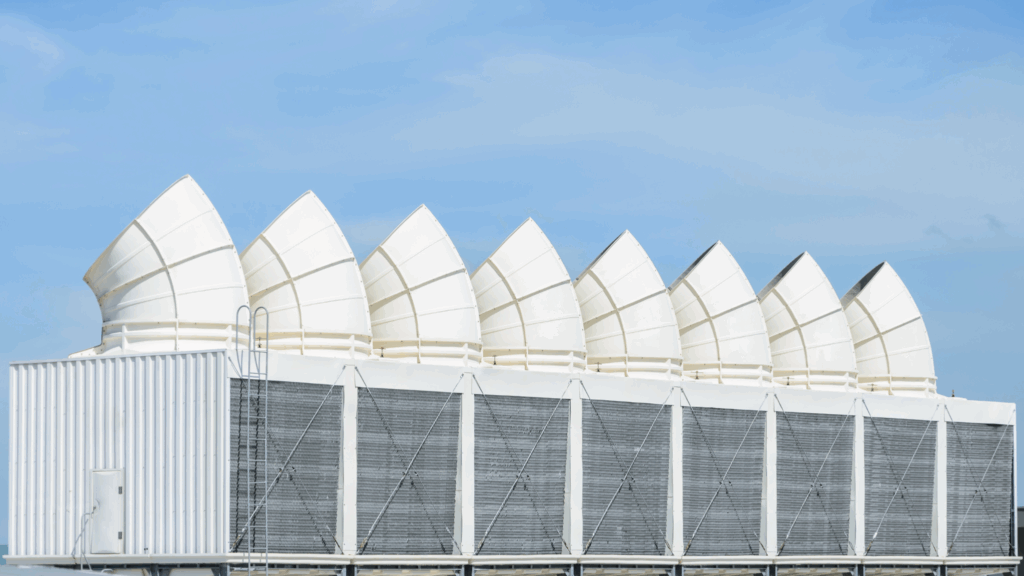

In nearly every industrial and institutional facility, the cooling water system plays a critical role in maintaining safe process temperatures, protecting equipment, and ensuring operational efficiency. Whether supporting massive power plants, university campuses, or hospital HVAC systems, cooling systems are the unseen backbone that allows production and comfort to run smoothly.

However, without proper maintenance, these systems are vulnerable to a range of challenges. Suspended solids, microbiological growth, and scale formation can accumulate in cooling towers and related equipment. Over time, these issues reduce efficiency, drive up energy and maintenance costs, and shorten the lifespan of system components. For facilities where uptime is essential, even small inefficiencies can have significant financial and operational consequences.

Filtration stands at the center of solving these challenges. By removing suspended solids and debris, filtration improves water quality, protects cooling towers and heat exchangers, and enables consistent performance across the system. It also reduces chemical demand and helps prevent corrosion, making it a vital partner to chemical treatment strategies.

This article explores why filtration is so important to cooling systems, how different filtration technologies work, and what role they play in keeping industrial and commercial facilities efficient and reliable. By understanding these fundamentals, facility managers and engineers can make better decisions to protect their investments and ensure long-term system performance.

Why Filtration Matters in Cooling Water Systems

A cooling water system is constantly exposed to suspended solids and biological activity that can compromise its performance. Even when makeup water is treated, airborne dust, pollen, fibers, and other contaminants can enter through the cooling tower. Without proper filtration, these impurities cycle through the system, accumulate in low-flow zones, and eventually foul sensitive equipment.

Controlling Suspended Solids and Biofilm

The risks go beyond surface debris. Suspended solids act as a breeding ground for microorganisms, accelerating microbiological growth that can create biofilm. Biofilm is especially damaging because it insulates heat transfer surfaces, reducing thermal performance while shielding bacteria from disinfectants. This leads to reduced efficiency in heat exchangers and higher chemical demand to maintain control.

Preventing Scale and Corrosion

Fouling also contributes to scale formation and corrosion. When solids and microbial deposits attach to pipes, fill media, and system components, they alter flow patterns and create localized hot spots. These conditions promote scaling from dissolved minerals and corrosion under deposits. If unchecked, the result is blocked passages, loss of water velocity, and damaged metal surfaces.

Reducing Operating and Maintenance Costs

The financial impact is significant. Facilities face higher operating costs due to increased pumping energy, frequent cleaning, and shortened equipment life. Emergency shutdowns or system failures can multiply those costs. By contrast, effective filtration captures debris before it can settle, helping to prevent corrosion, maintain stable operations, and keep maintenance costs predictable.

Safeguarding Long-Term Reliability

Filtration is therefore not just a support function but a critical safeguard. It protects water quality, ensures more consistent chemical treatment, and extends the life of vital assets. In industries where downtime is costly, such as healthcare, data centers, and manufacturing, filtration is indispensable to keeping the system reliable and efficient.

Also Read: Everything You Need To Know About Cooling Tower Filtration Systems

Types of Cooling Systems and Filtration Need

Not all cooling systems have the same requirements when it comes to filtration. The design of the system determines how water circulates, where contaminants enter, and what risks must be managed. Broadly, there are three major system types: once through cooling, open recirculating systems, and closed recirculating systems. Each has unique challenges that influence the need for filtration.

Once Through Cooling Systems:

As the name suggests, once through cooling draws water from a natural source, passes it through equipment to remove heat, and then discharges it back into the environment. While these systems are simple in design, they pose ecological concerns since heated discharge water can harm aquatic organisms and disrupt ecosystems. Filtration focuses mainly on protecting system components and heat exchangers from debris like leaves, sand, and silt using bar screens or traveling screens at the intake.

Open Recirculating Systems:

These systems, most often seen in cooling towers constructed for industrial and commercial use, recycle water continuously while cooling it through evaporation. Because they are open to the atmosphere, they readily collect dust, pollen, and organic matter. As the water cycles, contaminants concentrate, increasing the risk of scale formation, corrosion, and reduced efficiency. Effective filtration, in balance with water makeup and chemical treatment, is essential to maintain performance and prevent higher operating costs.

Closed Recirculating Systems:

Also called closed cooling water systems or closed loops, these circulate water in a sealed circuit that exchanges heat with a secondary system, such as a chilled water system or hot water loop. Although less exposed to airborne debris than open systems, they are still vulnerable to oxygen ingress through small leaks, which promotes corrosion. Circulating corrosion products can clog passages in sensitive equipment, reducing system reliability. Fine filters or side-stream filtration units are often installed to capture byproducts, which is especially important in critical applications like hospitals, power plants, and data centers.

Filtration Technologies in Cooling Water Systems

Filtration is not one-size-fits-all. Different technologies are used in a cooling water system, each suited to specific conditions, particle types, and facility needs. Choosing the right option can mean the difference between stable performance and recurring maintenance problems.

Centrifugal Separators

These filters use high-velocity flow to spin water in a circular motion, forcing heavier particles like sand or grit to the outer wall where they can be removed. They work well in recirculating cooling systems that face inorganic debris but are less effective on lightweight or organic matter. Since they have no moving parts or media, maintenance is minimal, making them attractive for industrial facilities that want reliability without frequent intervention.

Automatic Screen Filters

Water flows through a fine mesh or rigid screen, trapping particles. When the screen begins to clog, the filter cleans itself automatically, allowing continuous operation without taking the system offline. This makes them especially useful in industrial applications such as hospitals or process plants where interruptions are unacceptable. Screen filters are versatile, capable of protecting heat exchangers, circulating pumps, and other system components.

Plastic Disc Filters

These devices stack grooved discs together, creating a depth filter that captures particles as water passes through. They are effective against both inorganic solids and certain organics, making them suitable for facilities concerned with microbiological growth. Like automatic screens, many disc filters feature self-cleaning mechanisms. They are widely applied in open recirculating systems that must handle variable water quality while minimizing maintenance costs.

Sand Filters

Among the most widely recognized technologies, sand filters use layers of granular media to capture fine particles. Pressure sand filters can remove down to 10 microns, while high-efficiency designs can reach 0.45 microns. These filters are excellent at polishing water for sensitive equipment such as heat exchangers or systems running at high heat load. However, because the filter bed can promote microbial growth, supplemental oxidants such as chlorine dioxide may be used. Sand filters are common in cooling towers, chilled water systems, and even power plants where fine control over dissolved solids is needed.

Each filtration technology comes with trade-offs in cost, efficiency, and footprint. Some systems may even combine filter types to ensure comprehensive protection. The key is matching the filter to the type of solids present, the sensitivity of system components, and the operational demands of the facility.

Filtration and Heat Transfer Performance

At its core, the purpose of a cooling water system is to move heat from one location to another efficiently. Whether in a heat exchanger, a chilled water system, or a cooling tower, the ability of water to carry heat depends on both water quality and equipment condition. Filtration plays a direct role in keeping these pathways clear and effective.

- Protecting Heat Exchangers: Fouling from suspended solids and biological deposits creates an insulating layer on tube surfaces. Even a thin deposit can reduce the heat transfer coefficient, forcing the system to work harder. For example, a small increase in deposit thickness can drive a significant temperature difference across surfaces, lowering performance and increasing pumping energy.

- Maintaining Thermal Conductivity: Heat flows across multiple barriers in a heat transfer system: the water film, the tube wall, and the process side. If debris collects in the water film, it reduces effective thermal conductivity, limiting how well energy moves from one fluid to two fluids in contact through a solid barrier. Clean water keeps these resistances as low as possible, ensuring stable heat removal.

- Controlling Heat Load Stress: Industrial facilities operate under varying heat loads. When temperature increases coincide with fouling, the ability of the system to remove heat declines rapidly. Filtration ensures that water films remain thin and turbulence is preserved, helping to avoid hot spots and failures in process fluid circuits.

- Preventing Phase Change Inefficiencies: In evaporative cooling and condenser applications, scaling and deposits interfere with phase change processes. Instead of smooth vapor-to-liquid transitions, fouled surfaces trap bubbles and restrict condensation. This reduces overall heat transfer, drives higher operating costs, and can shorten the life of other equipment connected to the system.

Filtration, when combined with proper chemical treatment, keeps water clean enough to maintain turbulent flow and efficient thermal exchange. For facilities that rely on precise process temperatures, this means avoiding costly interruptions and extending the life of critical cooling assets.

Filtration for Closed Loop and Chilled Water Systems

Filtration needs in closed cooling systems differ from those in open towers. While closed loops are protected from the atmosphere, they are not immune to corrosion, oxygen ingress, and byproduct accumulation. Because these systems often serve critical applications, filtration plays a preventative role that ensures reliability.

Closed Loop Cooling Systems

In a closed system, water circulates through a sealed circuit to transfer heat to another medium. Small leaks, however, allow dissolved oxygen to enter, which accelerates corrosion. The resulting corrosion products travel with the circulating water and can deposit in narrow tubing or valves. Filtration is essential here to capture solids before they block passages or cause abrasive wear on sensitive system components.

Chilled Water Systems

A chilled water system supplies cold water, often in the range of 40–45 °F, to air handlers or process equipment. Since these systems must operate under precise process temperatures, fouling can quickly degrade performance. Filters help maintain clear water flow, reduce pressure drop, and protect heat exchangers from scaling or particulate buildup. They also reduce the demand on chemicals needed to inhibit corrosion in long runs of piping.

Hot Water Closed Loops

Facilities that operate hot water loops, such as in heating systems or industrial processes, face unique filtration challenges. Elevated temperatures accelerate corrosion, particularly in circuits built with carbon steel or copper alloys. Without filtration, oxides and particulates accumulate, leading to clogging and localized failures. Fine-mesh strainers or side-stream filters are often used to keep these loops clean and reliable.

Why It Matters

Because closed systems are used in sensitive environments like hospitals, data centers, and power plants, filtration is not optional. A well-designed filtration program ensures stable operation, extends asset life, and prevents unexpected failures that could disrupt essential services. When paired with routine monitoring and targeted chemical treatment, filtration is a critical safeguard against hidden risks inside closed loops.

Environmental and Operational Considerations

Filtration in a cooling water system provides more than just mechanical protection. It also supports sustainability, compliance, and operational efficiency. By reducing contaminants, facilities can balance performance with environmental responsibility while minimizing costs.

Water Conservation and Evaporation

In open recirculating cooling towers, water is continuously cycled, and a small fraction is lost through evaporation. As water evaporates, impurities like dissolved solids concentrate, creating a higher risk of fouling. Filtration helps control these solids, allowing operators to safely extend cycles of concentration and conserve water. With clean water, less water makeup is required, and less water lost to blowdown.

Energy Efficiency and Heat Transfer

Fouled equipment reduces heat transfer efficiency, forcing pumps, chillers, and towers to work harder. Clean water reduces resistance in the heat transfer system, lowering energy consumption and preventing higher operating costs. For facilities where ambient air temperature and process temperatures already push limits, filtration ensures reliable performance and stable control of temperature increases.

Air Cooling and Space Requirements

In some cases, facilities explore alternatives such as air cooling or hybrid designs to reduce water use. While these technologies can reduce dependence on evaporation, they often come with added space requirements and higher energy demand. By maintaining clean water, traditional evaporative cooling towers can remain the most efficient choice across many industries.

Industrial Applications and Compliance

Filtration also plays a role in meeting environmental standards. Industrial applications such as power generation, manufacturing, and healthcare often operate under strict discharge permits. By controlling suspended solids and organic matter in circulating water, filtration reduces the risk of noncompliance and ensures that many factors—from equipment longevity to environmental responsibility—are addressed simultaneously.

How EAI Supports Cooling Water System Reliability

Keeping a cooling water system clean and efficient requires more than filtration alone. Success comes from combining physical controls like filtration with targeted chemistry, monitoring, and expert service. That is where EAI’s Cooling Tower Water Treatment Service provides long-term value for industrial, healthcare, and institutional facilities.

Tailored Programs for Every Facility

Every cooling tower faces three critical threats: corrosion, scale, and biological fouling. Left unchecked, these problems reduce heat transfer, shorten the lifespan of system components such as heat exchangers, and drive up maintenance costs. EAI addresses these challenges with custom-designed programs that consider your water source, operating conditions, and facility demands.

Low-Dose, High-Impact Chemistry

EAI’s chemical programs are formulated for low dosage rates that extend cycles of concentration and reduce water makeup needs. From dispersants and scale inhibitors to pH balancers and biocides such as chlorine dioxide, our chemistry is designed to control scaling, inhibit corrosion, and suppress microbiological growth. This approach minimizes ecological footprint while keeping operations cost-effective.

Monitoring and Automation

Reliability depends on real-time insight. EAI integrates remote monitoring systems and automation tools to track water quality, temperature, and system performance. By calibrating controllers and chemical dosing equipment, we ensure stable operation even under changing process temperatures or ambient air temperature conditions. Alerts and trend analysis keep teams informed before problems escalate.

Onsite Expertise and Support

Our Certified Water Technologists (CWTs) perform routine onsite testing, corrosion coupon studies, and Legionella risk assessments to safeguard system health. Just as important, we train and support facility operators, ensuring they have the skills to manage daily operations and respond to system changes. This people-first philosophy aligns with EAI’s Total Water Management approach, combining chemistry, equipment, and service to deliver dependable results.

Commitment to Efficiency and Safety

With over 30 years of experience, EAI helps facilities extend equipment life, reduce higher operating costs, and support regulatory compliance. From closed loop programs in data centers to open recirculating systems in universities, we bring the expertise to keep cooling systems reliable, sustainable, and safe.

Conclusion

Filtration is a cornerstone of a healthy cooling water system. By removing suspended solids, controlling microbiological activity, and supporting efficient heat transfer, filtration protects critical assets and ensures that water systems perform reliably over the long term. From once through cooling to closed recirculating systems, every design benefits from the stability that clean water provides.

When paired with effective chemical treatment and expert monitoring, filtration minimizes downtime, reduces maintenance costs, and prevents the inefficiencies that lead to higher operating costs. For facilities across industries — healthcare, higher education, data centers, manufacturing, and more — filtration is not just about equipment longevity. It is about sustainability, safety, and operational confidence.

At EAI, we understand that every system faces unique challenges. That is why we deliver tailored solutions that combine filtration, chemistry, and people-first service to keep operations efficient and sustainable.

Contact EAI todayto schedule your onsite analysis and learn how we can help protect your cooling water system for the long term.

Frequently Asked Questions (FAQs)

How do suspended solids affect a cooling water system?

Suspended solids accumulate in recirculating water and deposit on heat transfer surfaces. These deposits reduce turbulence, lower the heat transfer coefficient, and encourage microbiological growth. Left unchecked, solids can trigger scale formation, corrosion, and ultimately reduced efficiency across the system.

What is the difference between open recirculating and closed cooling systems?

Open recirculating systems rely on evaporation to remove heat, exposing water to the atmosphere and contaminants. They require strong filtration and chemical treatment to control fouling.

Closed cooling systems, by contrast, circulate water in a sealed loop, such as in a closed recirculating or chilled water system. While less exposed, they are still vulnerable to oxygen ingress and the buildup of corrosion products, which filtration helps control.

Why are sand filters commonly used in industrial applications?

Sand filters can capture very fine particles, even below 1 micron in some designs, making them valuable in industrial applications where process fluid purity is critical. They are widely applied in cooling towers, chilled water, and hot water loops to maintain water clarity and support efficient operation.

Can chlorine dioxide replace filtration in cooling towers?

No. Chlorine dioxide is an effective biocide for controlling bacteria and biofilms, but it does not remove particulate matter. Filtration and chemical treatment work together: filtration removes solids, while chemistry helps inhibit corrosion, control deposits, and maintain water quality.

How does filtration reduce higher operating costs in power plants and other facilities?

When deposits restrict water velocity or reduce the surface contact between two fluids in a heat exchanger, efficiency drops and temperature differences rise. Pumps and circulating water systems must work harder, leading to higher operating costs. By keeping water clean, filtration reduces fouling, stabilizes process temperatures, and extends the life of system components and other equipment.