How Extreme Heat Affects Legionella Growth in Industrial Water Systems

Rising temperatures are more than just a comfort concern for building occupants, they can create ideal conditions for harmful bacteria to thrive in industrial water systems. Among the most concerning of these microorganisms is Legionella pneumophila, the bacterium responsible for Legionnaires’ disease, a severe and sometimes fatal form of pneumonia. Understanding the legionella temperature range and how extreme heat affects it is critical for facility managers, engineers, and water treatment professionals.

Recent events in New York City illustrate the urgency of this issue. A summer heatwave contributed to a Legionnaires’ outbreak in Central Harlem, traced to multiple cooling towers. The combination of high ambient temperatures and warm, stagnant water provided the perfect environment for legionella growth. These conditions are not unique to New York—states like Florida, Texas, and California also face persistent heat-related risks in healthcare, higher education, and industrial facilities.

In this article, we will examine the science behind Legionella’s temperature sensitivity, explore how extreme heat impacts hot and cold water systems, identify risk factors specific to industrial and commercial operations, and outline effective control measures. By understanding and managing temperature conditions, facilities can significantly reduce the risk of bacterial proliferation and protect water quality year-round.

Understanding the Legionella Temperature Range

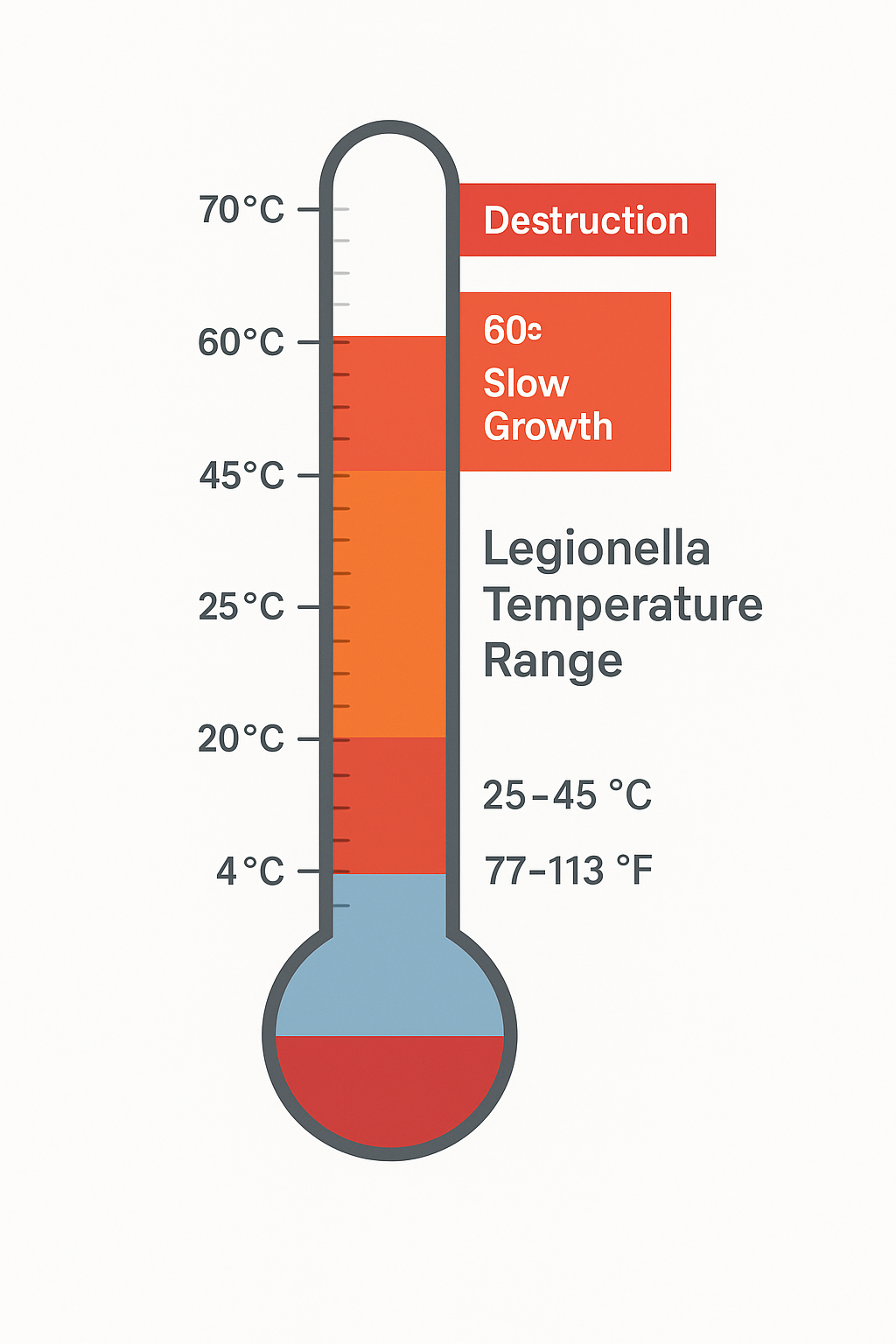

Legionella bacteria have a well-defined temperature preference, which is why temperature management is one of the most effective tools for controlling them. Centers for Disease Control and Prevention (CDC) shows that legionella growth occurs most readily within a legionella temperature range of approximately 20 to 45 °C (68 to 113 °F). The optimal zone for proliferation is 25 to 45 °C (77 to 113 °F), where nutrient availability, biofilm stability, and water conditions align to support rapid bacterial reproduction.

Below 20 °C, the bacteria remain dormant, and while they do not multiply, they can survive for long periods. Above 50 °C, bacterial activity slows significantly. At 60 °C, most legionella bacteria are killed within minutes, and at 70 °C or higher, destruction is near-instant. This is why temperature control in hot water systems is central to legionella control measures worldwide.

The risk arises when hot and cold water systems linger in the bacterial growth range. Cold water that warms due to poor insulation or high ambient temperatures, or hot water that cools during distribution, can both provide conditions that favor bacterial growth. Poor circulation, low-use fixtures, and dead legs can exacerbate the problem by creating pockets where water sits at temperatures ideal for bacterial multiplication.

Understanding this temperature relationship enables facility managers and engineers to set control limits for industrial processes, potable water systems, and cooling towers, ensuring that water remains outside the range where bacteria can thrive.

How Extreme Heat Alters Water System Conditions

Extreme heat doesn’t just make buildings uncomfortable, it shifts the way water behaves inside them. Elevated ambient temperatures can alter flow patterns, chemical stability, and thermal profiles in building water systems, creating conditions that favor legionella growth. These impacts can be seen across multiple system types and components.

Cold Water Systems at Risk

Extreme heat can push cold water temperatures into the legionella temperature range, especially in above-ground piping or poorly insulated cold water storage tanks. When ambient heat raises water above 20 °C, legionella growth becomes more likely, even in systems that are otherwise well maintained.

Loss of Disinfectant Residual

In potable water systems, high temperatures speed up the decay of disinfectant residual such as chlorine or chlorine dioxide. Without sufficient disinfectant levels, legionella bacteria can multiply rapidly within the distribution system, particularly in areas with low water turnover.

Cooling Tower Vulnerabilities

Cooling towers face increased heat loads during hot weather, which can lead to warmer basin water, higher nutrient levels, and faster bacterial growth. Without proper maintenance and consistent temperature control, these systems can become sources for Legionnaires’ disease outbreaks.

Stagnation and Low Use Zones

Periods of reduced occupancy in summer can lead to stagnant water in underused areas of a building. When this water sits at appropriate temperatures for legionella growth, and is not flushed or disinfected, it can quickly become a breeding ground for bacteria.

Key Risk Factors in Industrial and Commercial Facilities

Even with well-maintained building water systems, certain design features and operational conditions can amplify legionella risks during extreme heat. These vulnerabilities often require targeted control measures to keep water temperature and quality within safe limits.

Dead Legs and Low-Flow Areas

Sections of piping with little or no water movement, known as dead legs, create stagnant zones where water can settle into the legionella temperature range. These areas may be isolated from routine flushing and can harbor biofilm, making legionella control more difficult.

Insufficiently Protected Cold Water Storage Tanks

Poorly insulated or unshaded cold water storage tanks are prone to heating up during hot weather. Once cold water temperatures exceed 20 °C, the risk of legionella growth increases sharply, especially if tanks are oversized and water turnover is slow.

Thermostatic Mixing Valve Mismanagement

Thermostatic mixing valves are used to blend hot and cold water to reduce scald risk, but if they are set incorrectly, they can unintentionally maintain warm water within the bacterial growth range. Routine calibration and risk assessment are essential.

High-Risk Facility Types

Healthcare facilities, commercial facilities, and sites with complex air conditioning systems are particularly vulnerable due to the size and complexity of their water system components. Multiple storage points, hot water storage cylinders, and intricate piping increase opportunities for bacterial growth.

Legionella Control Measures During Heatwaves

During periods of extreme heat, routine legionella control strategies often need to be intensified. Higher water temperatures and changing usage patterns require a more proactive approach to minimize legionella growth and protect water quality.

Maintain Safe Temperature Limits

Ensure hot water systems store water at 60 °C or higher, and deliver it to outlets at a minimum of 51 °C. For cold water systems, keep temperatures below 20 °C. This prevents water from sitting within the legionella temperature range. These control limits are critical in hot water tanks, storage tanks, and hot water storage cylinders.

Boost Disinfection Protocols

Increased temperatures can reduce the effectiveness of disinfectants. Consider raising free chlorine or chlorine dioxide levels within safe regulatory limits to maintain a robust disinfectant residual. Some facilities may also benefit from hydrogen peroxide dosing during peak risk periods.

Thermal Shock and Pasteurization

Perform thermal shock treatments by temporarily elevating hot water to above 70 °C and flushing all outlets. This can help control legionella growth during outbreaks, though it must be balanced against scald risk and executed by trained personnel.

Flushing and Flow Management

Flush low-use outlets and circulation loops more frequently to avoid stagnant water conditions. Adjust water management program schedules to account for seasonal heat effects on water flow.

Cooling Tower Heatwave Response

Increase oxidizing biocide dosing, clean strainers and basins more often, and verify that fans, pumps, and dosing equipment are operating correctly. Heatwaves place additional strain on cooling towers, making consistent proper maintenance essential.

Read more on our blog: Legionella Treatment Options for Cooling Towers

EAI’s Expertise in Legionella Risk Reduction

Managing Legionella risks during extreme heat requires more than just good intentions—it demands proven strategies, regulatory knowledge, and hands-on expertise. EAI delivers comprehensive water treatment and water management program solutions across diverse industries, from healthcare facilities and hospitality to manufacturing, energy & power, and higher education environments. Our on-site services ensure that clients have a single point of contact for both chemical treatment and equipment support, streamlining operations and minimizing risk.

Learn more about Industries We Serve

For facilities with cooling towers, EAI brings over 30 years of experience in Legionella control measures and compliance with evolving regulations. Our programs follow ASHRAE, Cooling Technology Institute, OSHA, and local health department guidelines, ensuring that cooling towers remain compliant and safe year-round. Services include:

- Water Safety Plans to identify risks and define control measures before testing or disinfection begins.

- Tower cleaning and disinfection following CTI protocols, including pre- and post-oxidizing biocide applications, physical cleaning, debris removal, and full documentation.

- Microbial testing ranging from rapid onsite checks to certified lab analysis.

- On-line disinfection to address biological issues without taking systems offline.

- Tower inspections to identify low-flow areas, assess fill media and mechanical components, and verify circulation performance.

Check our Legionella Control in Cooling Systems

Whether performing scheduled maintenance or responding to an unexpected positive Legionella test, EAI’s cooling water safety services give facilities the confidence to operate safely during high-heat seasons. Our combination of technical expertise, rapid response capability, and adherence to industry best practices ensures clients are prepared to control legionella growth no matter the temperature outside.

Management Checklist for Preventing Legionella Growth

Technical measures alone are not enough to ensure safety in building water systems during extreme heat. The most effective programs combine operational protocols with strong management oversight, communication, and documentation.

1. Assign Clear Responsibility

Every facility should have designated personnel accountable for inhibiting legionella growth. This person or team must have both the authority and the resources to address risks promptly.

2. Keep Compliance Documentation Up-to-Date

Maintain accurate records of temperature control logs, disinfectant residual testing, and any corrective actions taken. Comprehensive documentation not only helps prevent legionella growth but also demonstrates due diligence in the event of regulatory review.

3. Communicate Risks Internally

Share seasonal advisories with maintenance staff, contractors, and building management teams. Clear communication ensures everyone understands the current temperature range risks and their role in protecting water safety.

4. Conduct Regular Risk Reviews

Schedule quarterly or seasonal reviews of risk factors with water treatment specialists. These reviews identify emerging vulnerabilities before they become costly or dangerous problems.

By focusing on management readiness as well as technical measures, facilities in healthcare, hospitality, manufacturing, and other high-risk industries can maintain control and protect public health during periods of extreme heat.

Download our Free Cooling Tower Inspection & Preventive Maintenance Checklist

Safeguarding Water Systems in the Heat of Summer

Extreme heat pushes building water systems into conditions where legionella bacteria can thrive, especially when temperatures drift into the legionella temperature range. By understanding how heat impacts both hot water systems and cold water systems, facility managers can take informed, proactive steps to prevent bacterial growth.

The strategies outlined—from maintaining safe control limits to boosting disinfection and implementing seasonal control measures—are essential for minimizing risk. Partnering with an experienced provider like EAI ensures that your water management program is built on proven best practices, regulatory compliance, and the ability to respond quickly to emerging threats.

Contact EAI today to strengthen your water safety program and ensure your team has the tools, training, and expert guidance needed to stay compliant and protect public health year-round.

Frequently Asked Questions (FAQs)

How does the Environmental Protection Agency guide Legionella prevention?

The Environmental Protection Agency (EPA) provides guidance for maintaining safe drinking water and potable water systems in commercial and industrial facilities. While Legionella control is often regulated at the state or local level, EPA resources support facility operators in understanding water quality parameters, disinfection practices, and water treatment options that help limit Legionella growth.

How do point of use filters help control Legionella risks?

Point of use filters are installed directly on fixtures, such as showers or taps, to physically block Legionella bacteria from reaching the user. They are especially valuable in healthcare facilities or other high-risk environments. While they don’t replace a full water management program, they can be part of targeted legionella control measures for vulnerable populations.

What role do thermostatic mixer valves play in Legionella prevention?

Thermostatic mixer valves blend hot and cold water to prevent scald risk, but if not properly adjusted, they can leave water system components at temperatures favorable to bacterial growth. Regular risk assessment and calibration by qualified air conditioning engineers or plumbing professionals is essential to minimize legionella growth.

Do water softeners have any impact on Legionella control?

Water softeners remove hardness minerals from water systems, which can reduce scale buildup inside storage tanks and water heaters. While they don’t directly kill Legionella bacteria, softer water can improve the effectiveness of chlorine based disinfectants and chlorine dioxide, supporting broader strategies to control legionella growth.