How to Calculate and Improve Cooling Tower Approach

A cooling tower’s performance is critical to the efficiency and reliability of industrial and commercial HVAC and process systems. One of the key indicators of this performance is the cooling tower approach, which measures how closely the tower can cool water compared to the ambient wet bulb temperature. Understanding, calculating, and improving the this approach helps facility managers optimize heat transfer, reduce energy costs, and ensure reliable tower performance. In this article, we’ll explore what cooling tower approach means, how it’s calculated, what factors influence it, and practical steps to improve it for better system efficiency.

Understanding Cooling Tower Approach

The cooling tower approach is defined as the difference between the temperature of the water leaving the tower (cold water temperature) and the wet bulb temperature of the air entering the tower. Essentially, it shows how close the cooling tower can get to the theoretical minimum temperature dictated by the surrounding air.

Since cooling towers rely on evaporative cooling, they can never cool water below the wet bulb temperature of the incoming air. This is because the wet bulb temperature represents the lowest temperature achievable through evaporation at a given relative humidity.

Several factors influence this relationship. For example, high humidity or insufficient air flow can increase the approach. Also, design conditions specified by the cooling tower manufacturer—including intended heat load, temperature difference, and expected atmosphere—set the baseline for acceptable performance.

A lower cooling tower approach generally indicates better efficiency, as the system is able to cool water closer to the wet bulb temperature.

Learn more in our blog: Cooling Tower Cleaning: Essential for System Efficiency

How to Calculate Cooling Tower Approach

Calculating the cooling tower approach is a straightforward process, but it requires accurate measurement of three key temperatures:

- Entering water temperature (hot water): The temperature of the water entering the cooling tower.

- Leaving water temperature (cold water): The temperature of the water after it has been cooled in the tower.

- Wet bulb temperature: The ambient wet bulb temperature of the air entering the tower, which can be measured using a psychrometer or similar instrument.

The formula is:

Cooling Tower Approach = Cold Water Temperature – Wet Bulb Temperature

It is important to distinguish the approach from the cooling tower range, which is the difference between the hot water and cold water temperatures. While the range indicates how much heat load has been removed, the approach tells you how close the cooled water comes to the wet bulb temperature, reflecting the tower’s heat transfer efficiency.

By monitoring both range and approach, you can assess whether your cooling tower is performing as designed, identify issues like fouling or inadequate evaporation, and ensure efficient tower performance.

Factors Affecting Cooling Tower Approach

Several factors can influence the cooling tower approach, making it essential to monitor and manage them carefully to maintain optimal performance.

- Evaporative cooling efficiency: The effectiveness of the evaporation process, which depends on ambient conditions and air flow, directly impacts how close the tower can cool water to the wet bulb temperature.

- Water circulation rate: If the water circulation rate is too low or uneven, heat may not be removed efficiently, increasing the approach.

- Pump speed and system balance: Improper pump speed or an imbalanced system can reduce contact time between water and air, leading to higher water temperatures.

- Makeup water and dissolved solids concentration: Poor-quality makeup water or high dissolved solids concentration can lead to scaling, fouling, or microbial growth, reducing heat transfer and increasing the approach.

- Tower design and manufacturer specifications: The cooling tower design and the standards set by the cooling tower manufacturer define expected performance under specific design conditions. Deviations from these can make achieving a low approach cost prohibitive.

- Atmosphere and weather conditions: Variations in relative humidity, temperature, and wind can change the effectiveness of heat removal, as the tower interacts with the surrounding atmosphere.

Understanding how these many factors work together is critical to maintaining an efficient tower and keeping the approach within acceptable limits.

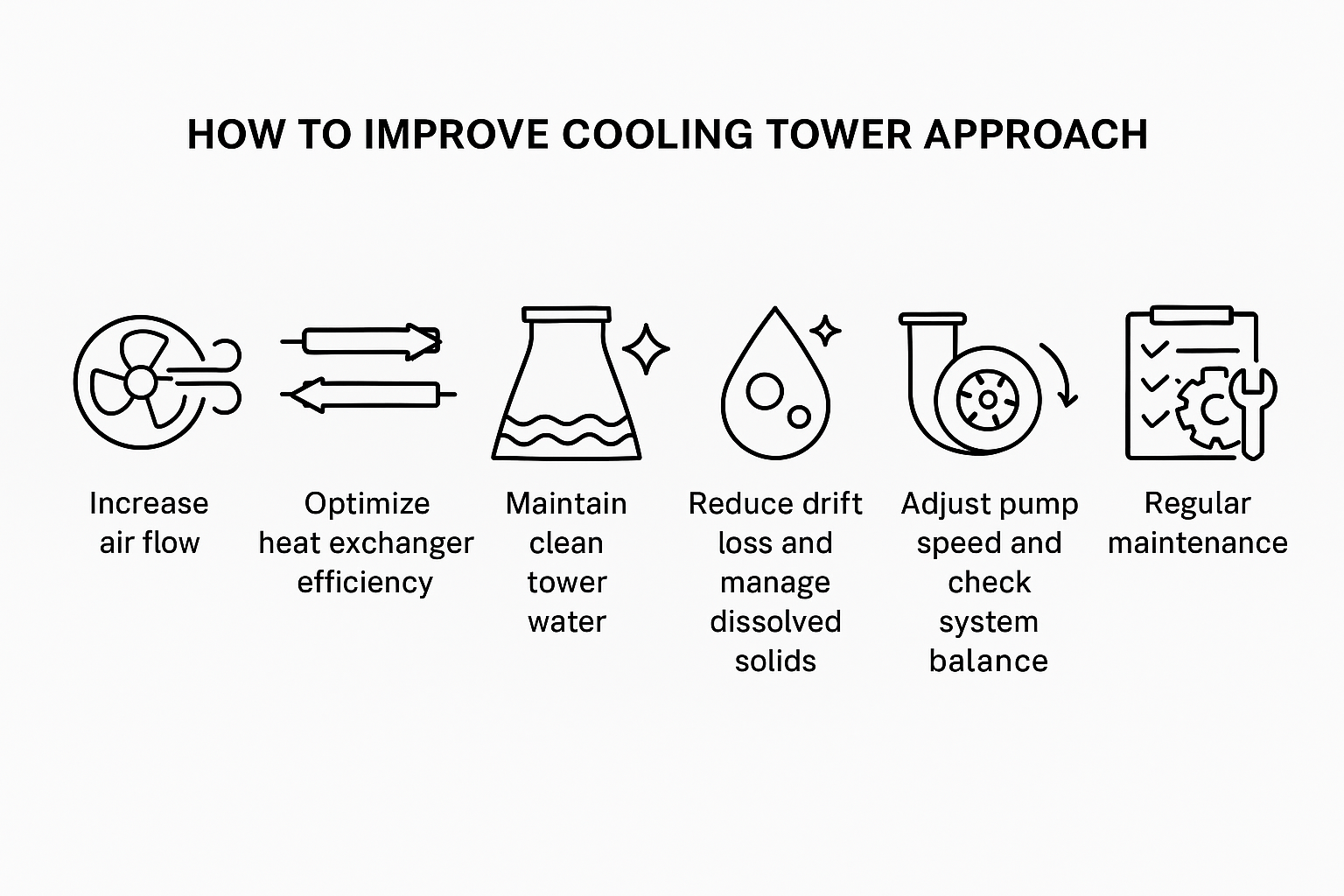

How to Improve Cooling Tower Approach

Improving the cooling tower approach involves optimizing the system to maximize heat removal and minimize inefficiencies. Below are practical strategies to achieve a better approach:

- Increase air flow: Enhancing air flow through fans, louvers, or baffles improves the evaporation rate and brings the water temperature closer to the wet bulb temperature.

- Optimize heat exchanger efficiency: Ensuring that heat exchangers are clean and free of deposits helps maintain effective heat transfer.

- Maintain clean tower water: Regular cleaning and water treatment reduce fouling, scaling, and biological growth in tower water, which can otherwise impede cooling.

- Reduce drift loss and manage dissolved solids: By minimizing drift loss and controlling the concentration of dissolved solids, you protect the tower from scale and corrosion that increase water temperature.

- Adjust pump speed and check system balance: Correct pump speed and balanced water circulation rate ensure uniform distribution and effective heat removal throughout the system.

- Regular maintenance: Consistent inspections and adjustments address many factors, including cooling range, temperature difference, and tower performance, to keep the system operating efficiently.

By focusing on these elements, facilities can reduce the tower approach, improve energy efficiency, and maintain reliable operation of their cooling towers.

EAI’s Expertise in Cooling Tower Optimization

At EAI, we help facilities achieve optimal cooling tower approach by addressing the key factors that impact tower performance. Our team of Certified Water Technologists and engineers works closely with you to design a comprehensive program tailored to your specific needs.

We offer:

- Preventative maintenance and onsite testing to maintain efficient tower performance

- Low-dose chemical treatment programs to reduce dissolved solids and protect equipment

- Remote monitoring and automated controls to manage heat load and detect issues in real time

- Customized water management plans aligned with your facility’s design conditions and operational goals

With over 30 years of experience, EAI combines chemical, mechanical, and operational expertise to keep your system running at peak efficiency.

Learn more about our Cooling Tower Water Treatment services and facility operator support to see how we can improve your heat transfer and extend the life of your equipment.

Why Cooling Tower Approach Matters for Your Facility

Monitoring and improving the cooling tower approach is essential for maintaining efficient operation, reducing energy consumption, and ensuring reliable tower performance. By understanding how to calculate the approach, recognizing the factors that influence it, and implementing targeted improvements, facilities can achieve better heat transfer and cost savings.

To ensure your cooling tower operates at its best, consider partnering with EAI’s team of experts for customized solutions and ongoing support.

Frequently Asked Questions

What is an example of a good cooling tower approach?

An example of a good cooling tower approach is typically in the range of 5–7°F for a well-maintained tower under design conditions. This can vary depending on the cooling tower design, wet bulb temperature, and specific heat load requirements.

How do cooling towers work to remove heat?

Understanding how cooling towers work is key: they cool circulating water by exposing it to air, allowing some water to evaporate, which removes heat from the system. This evaporation brings the water temperature closer to the wet bulb temperature of the incoming air.

Why does the wet bulb temperature in °F matter?

The f wet bulb (°F wet bulb) temperature is critical because it represents the lowest temperature that water can be cooled to through evaporative cooling. The closer the cold water temperature gets to this value, the more efficient the tower performance.

What happens if dissolved solids concentration increases?

When concentration increases in the cooling water due to evaporation and insufficient makeup water, it leads to higher dissolved solids concentration. This can cause scaling, fouling, and reduced heat transfer efficiency, making the tower approach higher.

How does cool water circulation impact tower efficiency?

Proper flow of cool water and balanced circulating water are vital to maintaining a low tower approach. Uneven flow or low rates can leave some areas under-cooled, increasing the temperature difference between cold water and wet bulb temperature, reducing efficiency.