Benefits of Chemical Dosing Pumps in Water Treatment

In water and wastewater treatment, precision is essential to achieving clean, safe, and compliant water. One critical component that ensures this precision is the chemical dosing pump. This type of pump is specifically designed to inject exact amounts of chemicals into a water system, helping maintain water quality and meet regulatory standards.

A chemical dosing pump, sometimes called a chemical metering pump, delivers controlled quantities of chemicals such as chlorine, acids, alkalis, or coagulants into water streams. These pumps are a cornerstone of water treatment and industrial applications, where the quality and safety of water depend on accurately controlling water chemistry.

By maintaining proper chemical balance, dosing pumps help prevent the growth of harmful bacteria, adjust pH levels, reduce waste, and protect water systems from corrosion or scale buildup. Whether in municipal water treatment plants, industrial facilities, or even swimming pools, these pumps play a critical role in keeping water clean and safe for its intended use.

How Does a Chemical Dosing Pump Work?

A chemical dosing pump operates by precisely injecting chemicals into a water stream at a controlled rate. The goal is to achieve accurate dosing, ensuring that the right amount of chemical is delivered to maintain water quality without overuse or waste.

These pumps use a combination of pumping action, valves, and control mechanisms to meter and deliver chemicals into the system. The pumping process begins with the liquid end, which draws in a measured amount of chemical. As the pump cycles, it pushes the chemical through an injection point into the water line.

Several key principles make this process effective:

- Metering and control: The pump measures the chemical to deliver precise chemical dosing, often adjustable based on the system’s needs.

- Stroke length and flow rate adjustment: Many dosing pumps allow operators to modify the stroke length or flow rate to meet changing water chemistry conditions.

- Chemical properties: The pump components are designed to handle various chemical properties, such as corrosive or viscous fluids, ensuring safe and efficient operation.

- Automated systems: In modern setups, chemical injection can be automated with sensors and controllers to maintain water chemistry without manual intervention.

The ability of metering pumps to inject chemicals precisely and consistently makes them indispensable in water treatment processes. They not only ensure proper disinfection and pH balance but also reduce the risk of over- or under-dosing, which can compromise both water quality and regulatory compliance.

Types of Chemical Dosing Pumps

Not all chemical dosing pumps are the same. Depending on the application, chemical properties, and required flow rates, different pump types are used to achieve accurate dosing. Each type of pump is specifically designed for certain tasks and offers unique advantages.

Below are the most common types of dosing pumps used in water treatment facilities, industrial applications, and wastewater treatment.

Diaphragm Pumps

Diaphragm pumps are among the most widely used chemical metering pumps. They use a flexible diaphragm and check valves to move precise amounts of liquid.

- Best suited for chemicals that are corrosive or hazardous.

- Provide high accuracy with adjustable flow rates and stroke length controls.

- Can operate at high maximum pressures, making them ideal for demanding water treatment processes.

- Effective for viscous fluids and aggressive chemicals thanks to robust materials in the liquid end.

Peristaltic Pumps

Peristaltic pumps use rollers to squeeze a flexible tube, pushing the chemical through in controlled pulses.

- Well-suited for chemicals that are abrasive, contain particulates, or are shear-sensitive.

- Excellent choice when pumping slurries or chemicals that might damage other pump types.

- Easy to maintain since the chemical only contacts the tubing.

Motor-Driven Pumps

Motor-driven dosing pumps combine the high torque of an electric motor with precise metering.

- Capable of handling larger volumes and higher pressures than smaller diaphragm or peristaltic pumps.

- Ideal for industrial water treatment applications where reliability and high output are required.

- Offer adjustable flow rates and can be integrated with automated control systems for efficient operation.

Choosing the Right Type

The right pump depends on several factors:

- Chemical properties: such as pH, corrosiveness, and viscosity.

- Flow rate and maximum pressure requirements of the system.

- Application: whether for municipal drinking water, wastewater treatment, or swimming pools.

- Maintenance preferences and cost efficiency expectations.

By understanding the strengths of each type of pump, operators can select the most effective solution for their water systems, ensuring precise chemical injection and long-term efficient operation.

Key Advantages of Using Chemical Dosing Pumps

A well-chosen chemical dosing pump delivers more than just chemicals—it ensures water quality, protects infrastructure, and supports sustainability goals. The ability to precisely inject chemicals into a water system offers several significant benefits for water treatment plants, industrial facilities, and even swimming pools.

Here are the key advantages of using chemical feed pumps in water treatment applications:

Accurate and Precise Chemical Dosing

- Dosing pumps are engineered for accurate chemical dosing, ensuring that the correct amount of chemical is delivered every time.

- This level of precision protects water systems from overdosing, which can damage equipment, and underdosing, which can allow harmful bacteria or imbalances to persist.

- Maintaining proper pH levels, disinfectant concentrations, and other chemical parameters is critical for water safety and compliance.

Maintaining Water Quality and Safety

- By delivering precise amounts of chemicals, these pumps help maintain clean water that meets health and regulatory standards.

- Proper disinfection and chemical balance help prevent the growth of bacteria, algae, and other harmful organisms, ensuring drinking water and process water are safe.

Reducing Waste and Environmental Impact

- Accurate dosing minimizes chemical overuse, which reduces both chemical waste and its environmental footprint.

- This contributes to sustainability goals while also lowering maintenance costs and conserving resources.

- Controlled dosing also helps facilities meet environmental regulatory compliance by limiting chemical discharge into waterways.

Enhancing Cost Efficiency

- With fewer wasted chemicals and reduced system damage, dosing pumps improve the cost efficiency of water treatment processes.

- Lower maintenance costs and longer equipment life lead to overall savings.

- Many pumps can be integrated into automated systems, which reduce labor requirements and increase operational reliability.

Meeting Regulatory Compliance

- Regulatory agencies set strict limits on water chemistry and contaminant levels in water treatment and wastewater treatment.

- Using precise chemical injection allows facilities to confidently meet these standards, avoiding penalties and protecting their reputation.

By offering a combination of efficiency, control, and environmental responsibility, chemical dosing pumps have become an essential part of modern water systems.

Applications of Chemical Dosing Pumps in Water Treatment

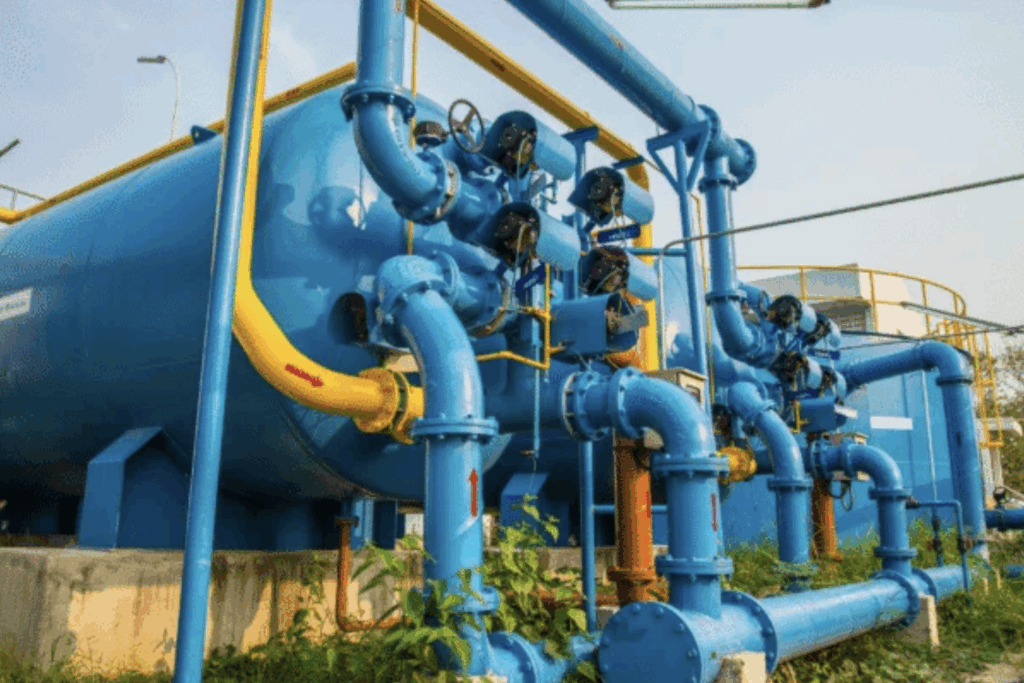

Chemical dosing pumps are used in a wide range of settings where water quality must be controlled and maintained. From municipal water treatment plants to industrial processes and even swimming pools, these pumps play a critical role in ensuring that water meets its intended use safely and effectively.

Below are some of the most common applications of dosing pumps in water treatment facilities and beyond.

Municipal Drinking Water Treatment

- Municipalities rely on dosing pumps to inject disinfectants such as chlorine and chlorine dioxide, maintaining safe drinking water.

- Pumps help adjust pH levels to prevent corrosion in distribution systems and ensure water meets regulatory standards.

- Accurate dosing protects public health and minimizes chemical overuse.

Wastewater Treatment

- In wastewater treatment, chemical dosing pumps inject chemicals to neutralize contaminants, reduce odors, and prepare water for safe discharge or reuse.

- Pumps deliver coagulants, flocculants, and disinfectants to meet environmental compliance and protect aquatic ecosystems.

- Maintaining proper water chemistry in wastewater processes is essential to protect both human health and the environment.

Industrial Applications

- Many industries, such as food processing, power generation, and manufacturing, use dosing pumps to control water quality in process water and cooling systems.

- Accurate chemical dosing prevents scale, corrosion, and microbial fouling, ensuring efficient operation of water systems.

- Industrial water treatment processes often involve complex water chemistry, making precise chemical injection indispensable.

Specialty Applications

- Facilities dealing with viscous fluids or challenging chemical properties also depend on specifically designed pumps.

- In some advanced systems, dosing pumps are integrated with sensors and automated systems for real-time adjustment and monitoring.

From keeping public water supplies safe to supporting industrial and wastewater treatment operations, chemical dosing pumps are indispensable tools in a variety of water treatment applications. Their ability to deliver precisely injected chemicals improves efficiency, safety, and compliance across all these settings.

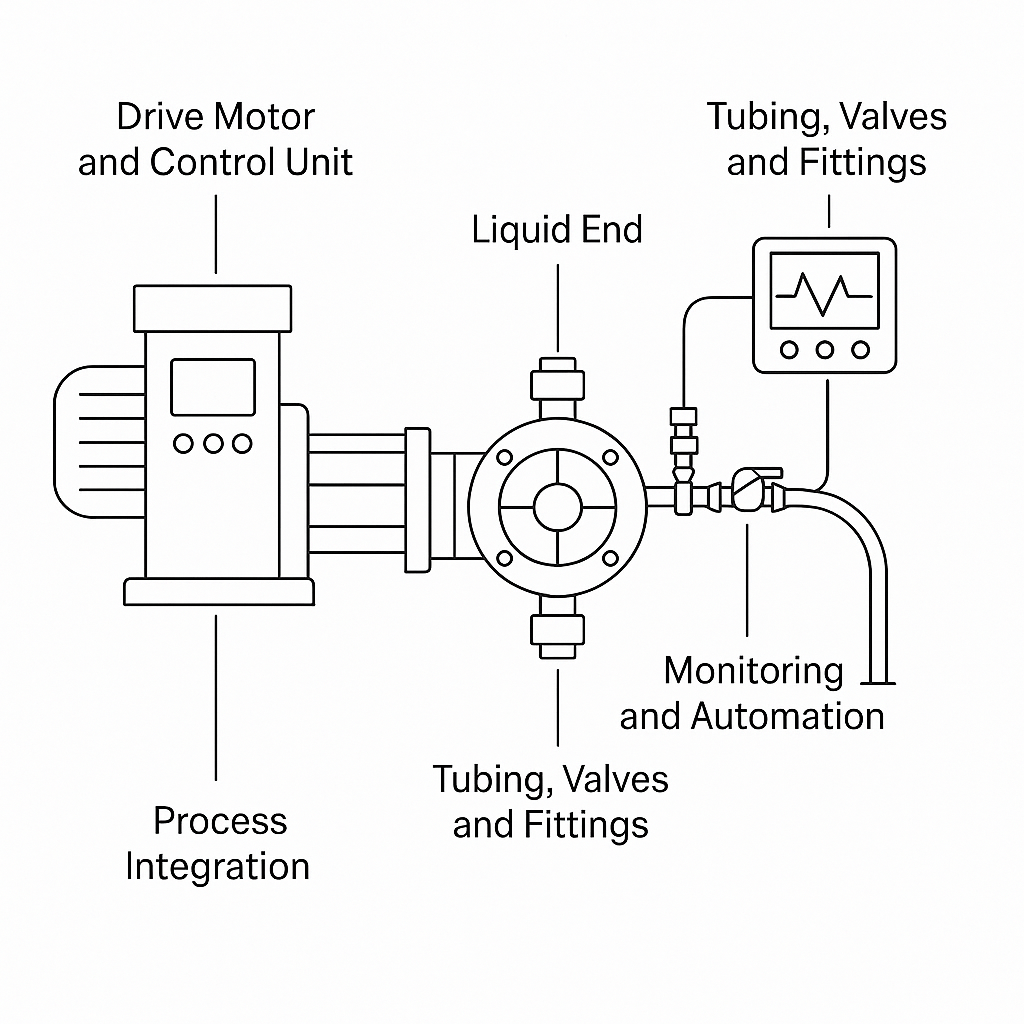

Components of a Chemical Dosing Pump System

A chemical dosing pump is more than just a pump — it is a system of coordinated components working together to deliver chemicals safely and accurately. Understanding the main pump components helps operators maintain proper function, identify issues, and ensure efficient operation.

Below are the key elements that make up a typical chemical feed pump system.

Drive Motor and Control Unit

- The motor provides the energy to drive the pumping mechanism, and in modern pumps, it often includes variable speed control for adjustable flow rates.

- The control unit allows operators to set parameters like flow rate, stroke length, and timing, ensuring precise dosing to meet specific process requirements.

- Automated systems may include programmable logic controllers (PLCs) and sensors for real-time adjustments.

Liquid End

- The liquid end is the part of the pump that comes in contact with the chemical. It includes the pump head, diaphragm or tubing, valves, and seals.

- Materials are chosen based on the chemical properties being handled to resist corrosion and wear, especially when dealing with aggressive or viscous fluids.

Tubing, Valves, and Fittings

- High-quality tubing and injection fittings are essential to deliver chemicals to the point of application without leaks or contamination.

- Valves prevent backflow and help maintain the correct pressure within the system.

Monitoring and Automation

- Many systems integrate sensors to monitor flow, pressure, and chemical concentration, ensuring precise chemical injection and compliance with regulatory standards.

- Automated systems reduce human error and allow operators to focus on higher-level system monitoring.

Process Integration

- Dosing pumps are designed to integrate seamlessly into the broader water systems and industrial processes, ensuring that chemicals are introduced at the correct point and in the correct amounts.

By understanding and maintaining each of these components, facilities can keep their chemical injection pumps operating reliably and cost-effectively, ensuring continued protection of water quality and system integrity.

How EAI Supports Your Chemical Dosing and Disinfection Needs

At EAI, we know that a chemical dosing pump is only as effective as the system around it. That’s why we deliver more than just pumps — we provide complete, integrated solutions that ensure precise chemical injection, regulatory compliance, and water safety across many industries.

Integrated Water Treatment Solutions

We support a variety of industries with our water treatment solutions, including:

- Municipal water treatment plants and wastewater facilities

- Healthcare and hospital water systems

- Food and beverage production

- Industrial processes and cooling systems

Our team works with you to:

- Evaluate your water chemistry

- Select the right pump type for your needs

- Install and calibrate your equipment properly

- Optimize dosing systems for efficiency, reducing costs and environmental impact

Advanced On-Site Chlorine and Chlorine Dioxide Generation

EAI also offers advanced on-site chemical generation systems, which integrate seamlessly with traditional dosing pumps to elevate your water treatment process. These systems generate disinfectants at the point of use, eliminating the need to transport or store hazardous chemicals.

Benefits of On-Site Generation:

- Cost-effective and sustainable

- Compliant with strict regulatory standards

- Safe and efficient, with minimal by-products

- Compatible with automated controls and remote monitoring

Our solutions include:

These systems are trusted in healthcare, food and beverage, and municipal applications for their reliability and ease of use.

Learn More and Take the Next Step

For a closer look at the key components that make up an effective dosing system, read our blog “Choosing the Right Chlorine Injection Pump for Your System“ to see how everything works together.

If you’re ready to upgrade your water treatment system with expert-designed solutions, contact EAI today. Our team is here to help your facility achieve clean, safe, and compliant water while minimizing costs and maintenance.

Contact us today and learn more about how we can help you.

Frequently Asked Questions

1. What are water treatment dosing pumps, and how are they used?

Water treatment dosing pumps are specifically designed to inject controlled amounts of chemicals into water systems. They ensure accurate and safe chemical addition in applications like drinking water treatment, wastewater treatment, swimming pools, and industrial processes.

2. Can dosing pumps handle both precise and adjustable flow rates?

Yes. Modern dosing pumps are capable of precise dosing while allowing operators to adjust the flow rate and stroke length based on water chemistry and system demand. This makes them versatile and effective in maintaining water quality.

3. How do dosing pumps help adjust pH levels in water?

Dosing pumps can be configured to inject acids or alkalis into water systems to adjust pH levels accurately. By delivering chemicals in exact amounts, they help maintain the correct water chemistry required for safe and efficient operation.

4. Are motor-driven pumps suitable for viscous fluids?

Motor-driven pumps are often the best choice for viscous fluids, thanks to their high torque and durable design. They can handle challenging chemicals that might be too thick or abrasive for other pump types.

5. What makes automated systems important in chemical dosing?

Automated systems reduce human error and allow real-time monitoring of flow, pressure, and chemical concentration. This ensures efficient operation, improves safety, and minimizes both maintenance costs and environmental impact.