Understanding Cooling Tower Drift Eliminators and Their Function

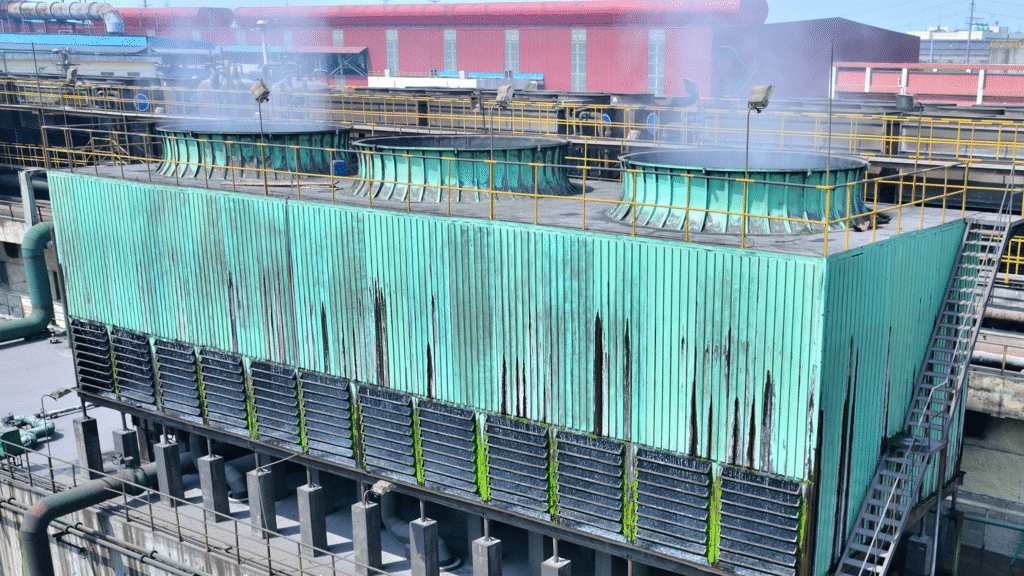

Cooling towers play a vital role in removing heat from industrial and commercial facilities by transferring it to the atmosphere through evaporation. However, during this process, water droplets can become entrained in the exhaust air and escape the tower. This unintended loss of water and chemicals is known as drift — and that’s where cooling tower drift eliminators come in.

Drift eliminators are engineered components designed to capture these droplets and return them to the system, improving water conservation, minimizing chemical loss, and reducing the risk of mist or chemical-laden air affecting surrounding areas. Let’s explore how drift eliminators work, the different types available, and their impact on cooling tower performance.

What Are Cooling Tower Drift Eliminators?

Cooling tower drift eliminators, often simply called drift eliminators, are slatted or cellular devices installed within the tower’s exhaust path. As air passes through them, the eliminators force a change in direction of airflow, causing entrained water droplets to lose velocity and impact the surfaces of the eliminator blades. The captured water then drains back into the tower’s sump rather than being lost to the atmosphere.

By removing droplets from the exhaust air, drift eliminators serve several important functions:

- Reduce water and chemical loss from evaporation and drift.

- Minimize the formation of mist around the tower that can damage nearby equipment or structures.

- Protect personnel and the environment by limiting airborne chemicals.

- Help facilities meet regulatory limits on drift emissions.

For facilities looking to further optimize their cooling tower water management, EAI Water offers comprehensive Cooling Tower Water Treatment programs that work alongside drift eliminators to reduce water use, protect equipment, and ensure compliance.

How Do Drift Eliminators Work?

The principle behind drift eliminators is simple but effective: by altering the direction of airflow and creating impact surfaces, they remove droplets from the airstream.

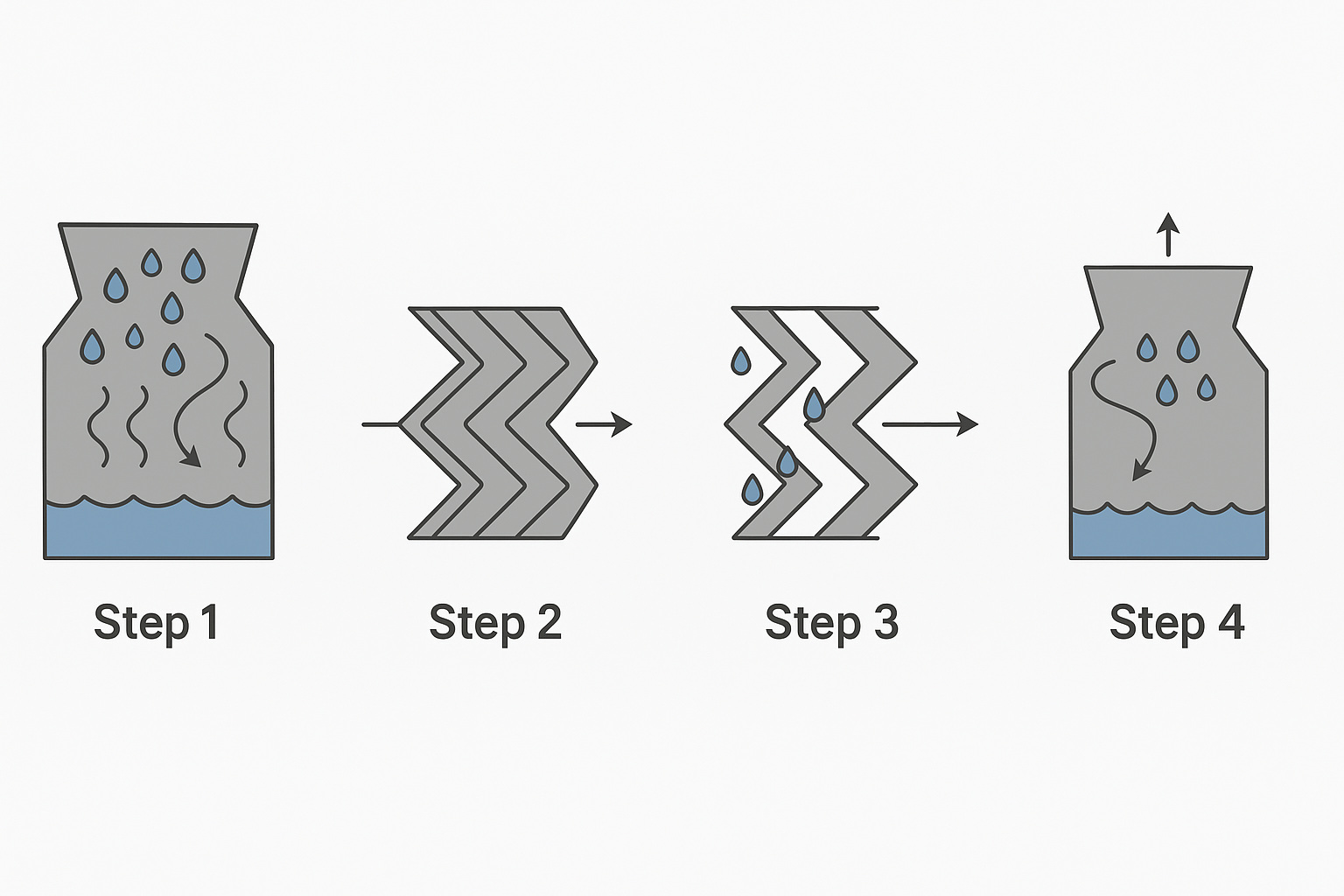

Here’s how it works step-by-step:

- As hot, moist air rises through the tower, it carries entrained water droplets.

- The air passes through the drift eliminator blades or cellular structures, which force it to change direction multiple times.

- Droplets, unable to follow the sharp turns due to their momentum, impact the eliminator surfaces and coalesce.

- The collected water runs back down into the tower basin, conserving both water and chemical treatments.

Because cooling towers operate under high velocity conditions and handle large volumes of water, the design and material of the eliminators are critical to their impact on performance and longevity.

Types of Cooling Tower Drift Eliminators

Drift eliminators come in different forms to suit various tower configurations and applications, such as crossflow or counterflow cooling towers. Below are the most common types:

1. Blade (Slat) Type

- Consist of parallel PVC or PP (polypropylene) blades spaced at precise intervals.

- Suitable for crossflow applications where air moves horizontally across the fill.

- Lightweight, easy to maintain, and cost-effective.

- Available in frame-supported assemblies for durability.

2. Cellular Type

- Feature a honeycomb-like structure made from PVC, PP, or even stainless steel.

- Ideal for counterflow towers due to their ability to handle higher air velocity.

- Offer superior drift reduction by forcing more directional changes in airflow.

3. High-Efficiency Eliminators

- Designed with advanced fill patterns and improved blade form to further reduce drift loss below regulatory thresholds.

- Often used in facilities where chemical conservation and environmental compliance are critical.

At EAI, our team helps clients select the right type of drift eliminator, considering tower configuration, support structure, and designed air and water flow range.

To learn more, visit our Cooling Tower Water Efficiency services.

Materials and Construction

The materials used in drift eliminators influence their durability, chemical resistance, and maintenance requirements. Common materials include:

- PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, and economical.

- PP (Polypropylene): Higher heat and chemical resistance, ideal for more demanding conditions.

- Stainless Steel: Extremely durable and resistant to high temperatures and aggressive chemicals, though more expensive.

Each material is designed to withstand prolonged exposure to water, chemical treatments, and environmental conditions, ensuring reliable performance over time.

Why Drift Eliminators Matter

The impact of effective drift eliminators goes beyond just water conservation. Here are some benefits in clear terms:

- Reduced water loss, saving operational costs.

- Lower consumption of treatment chemicals, improving sustainability.

- Minimized mist and droplets that can damage surrounding equipment and pose health risks.

- Improved compliance with environmental regulations.

- Longer frame and fill life by preventing water damage outside intended areas.

By incorporating the right drift eliminators as part of a comprehensive water management program — including quote and facility operator support from EAI, facilities can maintain their cooling systems efficiently and sustainably.

Partnering With EAI for Cooling Tower Performance

For more than 30 years, EAI Water has been providing tailored water treatment solutions for industrial cooling towers. Our Certified Water Technologists (CWTs) understand the role of tower drift eliminators, fill, frame, and other components in overall system performance.

Our team can help you:

- Evaluate your cooling tower’s design, range, and current eliminators.

- Recommend upgrades to improve water and chemical efficiency.

- Provide preventative maintenance, remote monitoring, and operator training to extend the life of your cooling tower.

Learn more about how our water management programs support your cooling tower performance and start saving water and costs today.

Visit our Cooling Tower Water Treatment page for more information.

Our experts are waiting to hear from you

Experience the EAI difference in water conservation and cooling tower performance. Schedule your onsite analysis or request a quote today!

Frequently Asked Questions (FAQ)

1. How do drift eliminators work in a cooling tower?

Drift eliminators force the airflow to change direction multiple times, causing water droplets to lose velocity, impact the blades, and drain back into the tower basin. This process improves water conservation and efficiency while keeping the exhaust air cleaner.

2. Do all cooling towers use the same type of drift eliminator?

No, the type and form of drift eliminator depend on the cooling tower design, whether it’s a crossflow or counterflow application, and the desired drift reduction performance. Both blade and cellular designs are used, and EAI can help you select the right one for your tower.

3. How often should drift eliminators be inspected or replaced?

While drift eliminators are designed to last for many years, they should be inspected regularly for cracks, scaling, or blockages that can reduce their effectiveness. Routine maintenance ensures they continue to minimize water and chemical loss and perform within regulatory limits.