Why Commercial Water Softener Installation Matters

Water quality is a critical factor in the smooth operation of many commercial and industrial facilities. Whether in manufacturing plants, restaurants, or office buildings, the quality of water impacts everything from equipment longevity to energy efficiency. One of the most common water quality issues faced by businesses is hard water. This refers to water that contains high levels of dissolved minerals such as calcium and magnesium.

Hard water can cause a variety of operational problems, including scale buildup in boilers, cooling systems, and plumbing, which reduces efficiency and increases maintenance costs. Over time, these minerals can lead to clogs, corrosion, and equipment degradation, all of which can negatively affect a facility’s bottom line.

With commercial water softener installation, businesses can effectively reduce the hardness of their water supply, ensuring that they get soft water that’s free of the minerals that cause damage and inefficiency. In this article, we’ll explore why commercial water softener installation matters and how it can benefit your facility’s operations and long-term efficiency.

What is Commercial Water Softener Installation?

Commercial water softener installation refers to the setup of a specialized system designed to remove hardness-causing minerals, such as calcium and magnesium, from the water supply. This process is typically achieved through ion exchange, where hard water ions are replaced with softer ions, usually sodium or potassium.

In a commercial setting, the installation of a water softener system involves assessing the specific needs of the facility, including water usage, flow rates, and hardness levels. A system size that is correct is essential for ensuring that the softener can handle the water demands of the business without overloading or underperforming.

Proper installation is crucial to ensure the water softener system operates at peak efficiency. This includes correct placement, configuring the system to meet the facility’s unique water requirements, and ensuring compliance with local codes for plumbing. A professional installation ensures that the system functions efficiently, providing softened water with minimal energy consumption and operating costs.

Benefits of Installing a Commercial Water Softener System

Installing a commercial water softener system can offer numerous benefits that positively impact both your facility’s operations and bottom line. From reducing scale buildup to improving energy efficiency, the advantages of softened water are clear. Here are some of the key benefits that businesses can expect from proper water softening:

1. Prevention of Scale Buildup

One of the primary reasons businesses invest in water softening systems is to prevent scale buildup caused by hard water. Scale can accumulate in pipes, boilers, heat exchangers, and cooling towers, creating blockages and reducing the efficiency of these systems. Over time, scale buildup acts as an insulating layer, reducing heat transfer and increasing energy consumption. By installing a commercial water softener, you can minimize this risk and keep systems operating at peak performance.

2. Reduced Maintenance Costs

Scale and corrosion caused by hard water can lead to frequent maintenance and repairs. Installing a water softener system reduces these issues, ultimately lowering maintenance costs. Without the need to repair or replace components affected by mineral buildup, businesses can save on both labor and materials. Softened water also reduces the need for chemical treatments, such as scale inhibitors, further decreasing operational costs.

3. Increased Energy Efficiency

When hard water causes scaling in heating and cooling systems, the systems have to work harder to maintain the desired temperature, leading to increased energy consumption. With softened water, these systems can operate more efficiently, lowering energy bills and reducing environmental impact. NBBI highlights that even a small layer of scale buildup can decrease boiler efficiency by more than 20 percent, making softened water an effective way to cut energy costs.

4. Extended Equipment Lifespan

By reducing scale buildup and corrosion, a commercial water softener system helps extend the lifespan of critical equipment. Boilers, heat exchangers, and piping systems last longer when they are protected from the harmful effects of hard water. This not only reduces the frequency of equipment replacements but also maximizes the return on investment in infrastructure.

5. Improved Water Quality

Softened water also improves the quality of water used in various commercial applications. Whether for cleaning, food production, or other processes, softened water reduces the use of harsh chemicals and improves the performance of systems such as dishwashers, washing machines, and cooling towers. Consistently high-quality water leads to better product quality and fewer operational disruptions.

By installing a commercial water softener system, businesses can address these challenges, ensuring a reliable water supply while lowering operational costs, improving efficiency, and extending equipment life.

EAI Industrial Water Softener Services

At EAI Water, we understand that every facility has unique water softening needs. That’s why we offer commercial water softener installation services tailored to your specific water quality, usage patterns, and operational goals. Whether you need a small system for a restaurant or a large-scale solution for an industrial plant, we have the expertise to provide you with the right system to optimize your water quality and reduce operational costs.

Customized Water Softener Systems

Our water softener systems are engineered to meet the unique needs of your facility. We take into account factors such as continuous flow rates, system design, and water hardness levels to ensure that the system is properly sized and installed for maximum efficiency. Our team works closely with you to identify the most effective solution for your business, ensuring that your softener system delivers reliable performance and meets all regulatory standards.

Professional Installation

Proper installation is key to ensuring that your water softener system operates at peak efficiency. Our team of experienced technicians will ensure that your system is installed according to local plumbing system codes and customized to meet your business’s unique water treatment needs. We also provide guidance on maintenance and operation to help you maximize the life and effectiveness of your system.

Ongoing Maintenance and Support

Regular maintenance is essential to keep your water softener system running smoothly. At EAI Water, we offer comprehensive support services for all types of water softening systems, including monthly calibration, inspection, and troubleshooting. Whether you need routine check-ups or urgent repairs, we’re here to ensure that your system operates at peak performance, reducing downtime and extending the life of your equipment.

For more information about our commercial water softener installation and pretreatment services.

Case Study: Industrial Facility Improvement with Water Softener Solutions

A large food processing facility in Southern California was facing significant challenges related to hard water. The mineral buildup in their boilers and cooling systems had led to scale formation, which reduced heat transfer efficiency, increased energy consumption, and caused frequent equipment failures. The facility also experienced increased maintenance costs as they had to replace parts and repair systems damaged by scale buildup.

Challenges

- Scaling in Heat Exchangers & Boilers: Mineral deposits in the system reduced heat transfer efficiency, forcing the equipment to work harder, leading to higher energy consumption.

- Excessive Water & Chemical Use: Frequent regeneration cycles consumed large amounts of water and salt, increasing operating costs.

- Aging Softener Equipment: The existing water softener system lacked modern automation and real-time monitoring, resulting in inconsistent performance and increased maintenance needs.

Solution: EAI Water’s Customized Water Softener Retrofit

EAI Water conducted a comprehensive assessment of the facility’s water treatment needs and recommended a tailored softener retrofit to address the specific challenges. We replaced the aging resin beds with high-performance media, upgraded the control systems to programmable logic controllers (PLCs) for automated regeneration cycles, and integrated remote monitoring capabilities to allow real-time performance tracking.

Results

- Energy Savings: After the retrofit, the facility experienced improved heat exchanger efficiency, leading to a 20% reduction in energy consumption.

- Reduced Water Waste: By optimizing the regeneration cycles, the system significantly lowered blowdown waste, reducing water usage by 30%.

- Extended Equipment Lifespan: With less scale buildup, the facility’s boilers and cooling towers have experienced fewer breakdowns and extended service life.

- Lower Chemical Usage: The upgraded system reduced the need for scale inhibitors, contributing to both cost savings and environmental sustainability.

The facility’s operations manager expressed their satisfaction with the new system: “Since implementing the EAI Water softening solution, we’ve seen remarkable improvements in system efficiency and a noticeable reduction in maintenance costs. The team did an excellent job!”

Read the full case study: Industrial Facilities That Improved Water Efficiency with Softeners

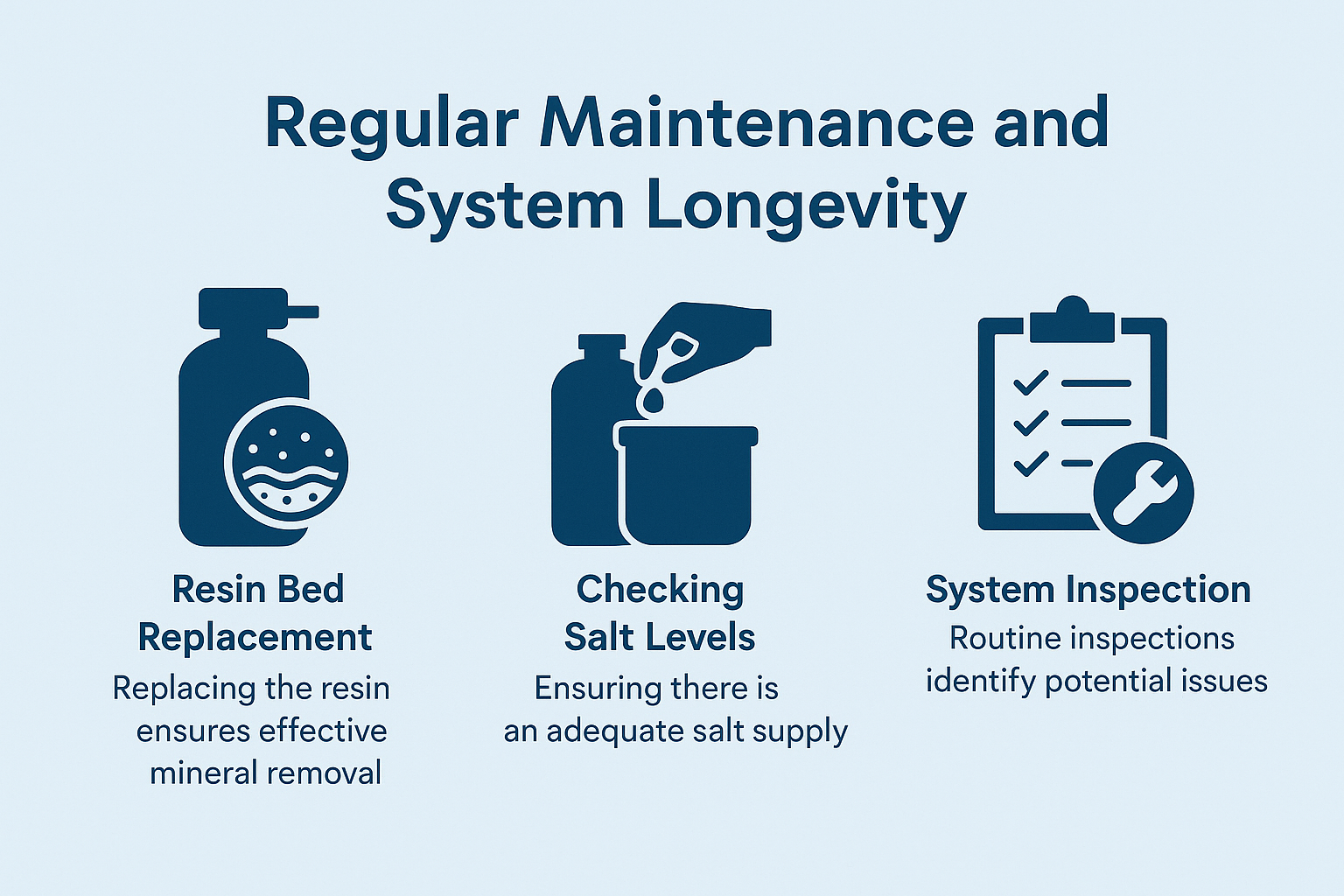

Regular Maintenance and System Longevity

Regular maintenance is essential to ensuring that your commercial water softener system continues to function at optimal efficiency over its lifespan. Just like any other piece of equipment, water softeners require periodic checks and maintenance to maintain peak performance and avoid unnecessary breakdowns.

Key Maintenance Tasks

- Resin Bed Replacement: Over time, the resin bed in your water softener system will lose its effectiveness. Replacing the resin ensures that the system can continue to remove hard water minerals effectively.

- Checking Salt Levels: The brine tank must be regularly checked to ensure that there is an adequate supply of salt to regenerate the resin. Low salt levels can cause the system to fail and allow hard water minerals to pass through.

- System Inspection: Routine inspections by trained technicians will help identify any potential issues before they become major problems, such as leaks, valve malfunctions, or buildup in the system.

Proactive vs. Reactive Maintenance

Proactively maintaining your water softener system can significantly extend its lifespan, improve energy efficiency, and prevent costly emergency repairs. Partnering with a professional service provider like EAI Water ensures that your system receives regular attention and timely repairs to minimize downtime and operational disruptions.

Investing in Long-Term Efficiency with Proper Water Softener Installation

Installing a commercial water softener system is a crucial step for any facility that wants to improve water quality, extend the life of its equipment, and reduce operational costs. From preventing scale buildup and lowering energy bills to ensuring consistent water quality, the benefits of softening your water are clear.

At EAI Water, we specialize in designing, installing, and maintaining commercial water softener systems tailored to meet the unique needs of your facility. Don’t wait for hard water to affect your business, invest in a solution that will help you operate more efficiently and sustainably for years to come.

Contact us today to schedule a consultation or learn more about how commercial water softener installation can improve your facility.

Frequently Asked Questions (FAQs)

1. How does the capacity of a water softener system vary depending on the facility’s needs?

The capacity of a water softener system varies depending on factors such as water usage, flow rate, and hardness levels. A larger facility with higher water demands will require a system with greater capacity to ensure consistent performance.

2. Is electrical work required for installing a commercial water softener system?

Yes, electrical work may be necessary to integrate the water softener with your facility’s power supply, particularly for systems with automated controls or remote monitoring capabilities. It’s important to hire a professional to ensure proper installation.

3. What are the many benefits of installing a commercial water softener system?

Installing a commercial water softener system offers many benefits, including improved water quality, reduced scale buildup, lower maintenance costs, and increased equipment lifespan. It also helps reduce energy bills by improving the efficiency of boilers and cooling systems.

4. How much space is needed for a water softener system?

The amount of space required for a water softener system depends on the system’s size and configuration. Smaller systems may fit in tight spaces, while larger systems may require more room. A professional can assess the available space to determine the best system for your needs.

5. How does the size and capacity of a water softener system affect its performance?

The capacity of a water softener system determines its ability to handle the water usage and hardness levels of your facility. A properly sized system ensures optimal performance, avoiding overloading or underperformance.

6. What role do filters play in water softening systems?

Filters are an essential part of water softener systems, helping to remove impurities and particulate matter from the water before it passes through the softening process. This ensures that only softened water is used in your facility’s operations.

7. How can I make my water softener system more efficient?

To make your water softener system more efficient, ensure that it is properly sized for your facility, regularly maintained, and optimized for the specific water hardness and flow rate of your facility. Additionally, consider upgrading to a system with automatic controls for better performance.