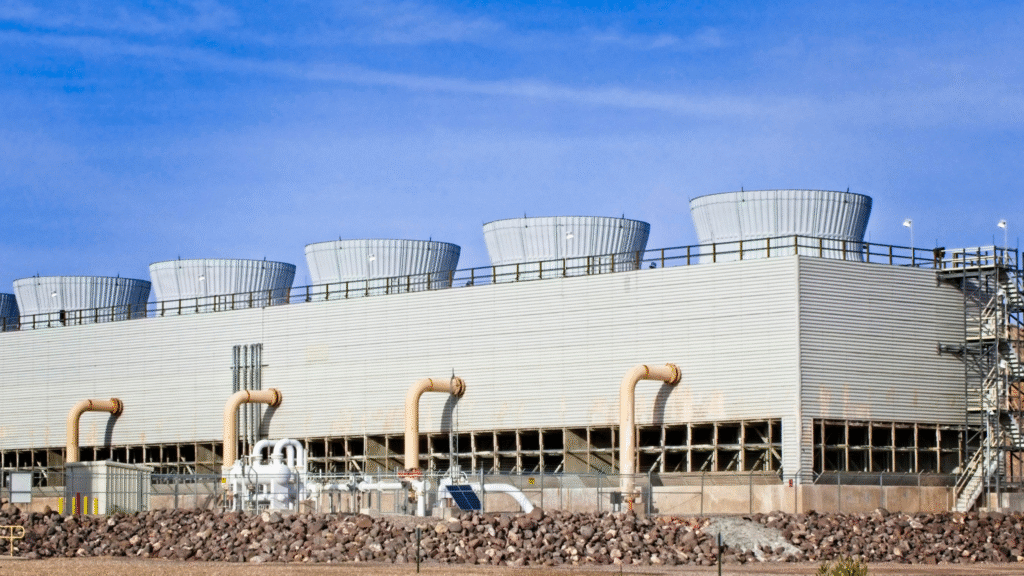

Cooling Tower Cleaning: Essential for System Efficiency

Cooling towers are critical to HVAC system and industrial operations, but they’re also magnets for dirt, scale, and microbial growth. Over time, that buildup doesn’t just look bad, it disrupts water flow, impairs heat exchange, and accelerates equipment wear. Without proper cleaning, your entire cooling tower system loses efficiency, uses more energy, and risks serious health concerns like Legionella bacteria.

For facility managers responsible for peak performance and safety, cooling tower cleaning isn’t just another line item on a checklist. It’s a foundational step in ensuring clean water, long-lasting equipment, and reliable cooling performance.

Why Cooling Tower Cleaning Matters for Your Facility

Cooling towers work by transferring heat from water to the air, but that process is only effective when the system remains clean. As cooling tower systems run, they naturally accumulate organic matter, scale deposits, and airborne debris. This buildup creates the perfect breeding ground for microbial growth, including algae, biofilm, and even Legionella bacteria which is a serious health risk regulated under ASHRAE 188 and other standards.

But the risks aren’t limited to health. Dirty towers degrade system performance in several ways:

- Clogged nozzles reduce uniform water distribution

- Scale deposits insulate heat transfer surfaces

- Biofilm interferes with heat exchange and water flow

- Algae and sludge increase corrosion risks in the cooling tower basin

Even if your water treatment program is dialed in, dirt and biological material will eventually accumulate. That’s why tower maintenance must include regular physical cleaning alongside chemical water treatment. It’s the only way to restore efficiency and reduce energy and water costs.

What Gets Dirty in a Cooling Tower? Key Trouble Zones

While a cooling tower looks clean on the outside, the real problems might have built up in the components you can’t easily see. Over time, contaminants like dirt, debris, algae, and sludge settle into the system, affecting both mechanical function and water quality.

Here are the key areas where buildup occurs:

1. Cooling Tower Basin (Sump)

This is the lowest point in the system where water collects and recirculates. It’s also a catch-all for sediment, scale flakes, and biological matter. A dirty basin not only reduces water quality, but also increases the risk of corrosion, bacteria, and clogged pumps.

2. Fill Media

The fill enhances heat exchange by increasing surface area, but it’s also a magnet for biofilm, algae, and scale. If fouled, airflow is restricted and thermal efficiency drops significantly.

3. Nozzles and Spray Systems

These distribute water needed over the fill media. When dirt or sludge clogs nozzles, it creates uneven distribution, promoting dry spots and scale formation.

4. Air Inlet Louvers and Drift Eliminators

These control airflow, but can become obstructed by organic debris or mold. Dirty air components reduce system ventilation and increase fan workload.

In short: if you’re not inspecting and cleaning these areas, you’re not getting full value out of your cooling tower cleaning efforts.

The Cooling Tower Cleaning Process: Step by Step

Effective cooling tower cleaning isn’t just about spraying off visible dirt. It’s a detailed, multi-step process that targets biological contaminants, mineral scale, and debris across the entire HVAC system. Whether scheduled during planned downtime or as part of a seasonal maintenance program, this cleaning routine helps restore performance and prolong equipment life.

Here’s what a typical cleaning process looks like:

1. Drain the System

The first step is to completely drain the cooling water basin and system piping. This allows access to internal components and prevents dirty water from re-entering the system after cleaning.

2. Remove Loose Debris and Sludge

Physical removal of dirt, leaves, biological matter, and sludge is next. This includes vacuuming the basin, scooping out heavy buildup, and clearing sump screens. If left unchecked, this debris can damage pumps, reduce flow, and contribute to microbial growth.

3. Clean Fill Media and Nozzles

Technicians clean or replace fill media that has been fouled by scale deposits, algae, or biofilm. Nozzles are checked for clogs and cleaned to restore proper spray patterns, which is essential for even water distribution and heat transfer.

4. Disinfect and Treat the System

After physical cleaning, the entire system is disinfected using appropriate biocides to eliminate residual bacteria, including Legionella. This step is critical for protecting human health and meeting safety regulations.

5. Rinse and Inspect

Following disinfection, the system is rinsed thoroughly with clean water to flush out chemical residues and remaining contaminants. During this step, technicians also inspect for damage or signs of wear in components like fans, motors, and drift eliminators.

6. Refill and Restart

The system is refilled with treated water, brought back online, and monitored for performance. Water chemistry is balanced, and filters are checked to ensure optimal operation moving forward.

The Operational and Environmental Benefits of Regular Cleaning

Many facility managers view cooling tower cleaning as a once-a-year task, or worse, a reactive fix after performance starts dropping. But consistent, regular cleaning provides long-term operational and environmental benefits that extend far beyond basic cooling tower maintenance.

1. Boosts Energy Efficiency

Clean surfaces improve heat exchange, allowing your system to reject heat more effectively. When scale and biofilm are removed, water cools faster, fans and pumps run less often, and you use less electricity. That translates to lower utility bills and a smaller carbon footprint.

2. Reduces Water Usage

Fouled towers require more blowdown and chemical treatment to maintain water quality. Clean towers, on the other hand, use less water and reduce waste. By improving system cleanliness, you minimize unnecessary refill cycles and chemical load.

3. Extends Equipment Life

Contaminants like scale, algae, and sludge corrode internal components and stress your equipment. Removing these elements during cleaning reduces wear on pumps, nozzles, and fans, helping you avoid costly repairs and replacements.

4. Improves System Performance

Clean systems run more predictably and require less frequent troubleshooting. Tower components (i.e. fill media, sump pumps, and filters) perform as designed, keeping water flowing and temperatures in check during high-demand conditions.

5. Enhances Health and Safety

Finally, regular cleaning is critical for microbial control. A dirty cooling tower basin can harbor Legionella bacteria, leading to regulatory violations or serious health risks. Cleaning, disinfection, and water treatment work together to ensure your system is both efficient and safe.

How EAI Supports Cooling Tower Cleaning and Performance

At EAI, we know that effective cooling tower cleaning is only one piece of a larger water management strategy for facility managers. That’s why our programs combine physical cleaning with advanced water treatment, remote monitoring, and hands-on technical support to keep your system running at peak performance year-round.

Our Certified Water Technologists (CWTs) design customized service plans for every facility, starting with a thorough analysis of your tower, feedwater quality, and operational demands. From corrosion and scale control to biological fouling prevention, our treatment programs are built to maximize efficiency and extend equipment life without overusing water or chemicals.

EAI’s cooling tower programs include:

- Low-dose chemical treatments for scale, corrosion, and biofilm

- Automated controllers and remote monitoring

- Onsite testing, Legionella risk management, and tower disinfection

- Preventative maintenance and operator training

Whether you manage a hospital, university, or industrial facility, our expert team is here to support long-term performance and water conservation goals.

Learn more about EAI’s Cooling Tower Water Treatment services

See our case study on UC Irvine that innovated with Cooling Tower Water Reuse

Don’t Wait, Make Cooling Tower Cleaning Routine

Skipping or delaying cooling tower cleaning puts your system at risk for higher costs, health hazards, and performance failure. A clean tower means better water flow, lower energy use, and longer equipment life.

Let EAI help you build a cleaning and treatment program tailored to your facility.

Contact our team today to schedule a consultation