Chlorine Dioxide Biofilm Control in Cannabis Dripper Systems

As the legal cannabis industry matures, operators are investing heavily in greenhouse automation, fertigation, and environmental control systems. Yet one overlooked challenge continues to plague even the most sophisticated facilities: clogged drippers.

Drip irrigation systems are prized for their precision and efficiency, but they’re also highly susceptible to clogs. These clogs create uneven water and nutrient delivery, stunt plant growth, and ultimately lead to reduced yields. And in most cases, the root cause is biofilm: a resilient, slimy matrix of bacteria and organic compounds that thrives inside moist irrigation lines.

Chlorine dioxide biofilm control offers a game-changing solution. Unlike conventional sanitizers like bleach or hydrogen peroxide, chlorine dioxide is a selective oxidizer that targets biofilm without corroding equipment or altering pH. For cannabis companies looking to maintain peak system performance and stay compliant with water quality standards, chlorine dioxide is becoming the disinfectant of choice.

In this article, we’ll explore how chlorine dioxide generators work, why it’s ideal for cannabis greenhouses, and how EAI’s generator systems make it safer and easier to implement.

Understanding the Biofilm Problem in Drip Irrigation

Drip irrigation is a cornerstone of modern cannabis cultivation. It conserves water, delivers nutrients directly to the root zone, and supports consistent plant development. But over time, even high-efficiency systems face a common enemy: biofilm.

Biofilm forms when microbial communities (primarily bacteria, algae, and fungi) attach to internal surfaces of irrigation lines and emitters. These microorganisms produce a sticky protective layer of extracellular polymeric substances (EPS), allowing them to resist flow, oxidants, and cleaning efforts. Once established, biofilm becomes a breeding ground for further microbial growth and a trap for sediment, minerals, and organic debris.

In cannabis greenhouses, biofilm-related clogging is especially problematic. The warm, nutrient-rich environment is ideal for bacterial growth. Drip lines with low or inconsistent pressure become hotspots for buildup, particularly in systems with long runs, recirculated water, or inadequate filtration.

As clogs progress, water flow becomes uneven. This leads to plant stress, inconsistent yields, and wasted resources. Worse, frequent manual flushing or emitter replacements add labor and increase operational downtime. For commercial growers producing cannabis products at scale, ignoring biofilm is a recurring cost and a reliability risk.

Why Chlorine Dioxide Works: Chemistry Behind Biofilm Disruption

Chlorine dioxide biofilm treatment is fundamentally different from traditional sanitizers. Unlike chlorine, which forms reactive by-products like trihalomethanes (THMs), or hydrogen peroxide, which degrades quickly and lacks targeting precision, chlorine dioxide (ClO₂) is a selective oxidizer. This means it targets and penetrates the biofilm matrix without reacting unnecessarily with other organic material or altering the surrounding water chemistry.

Once inside the biofilm, chlorine dioxide attacks the structural EPS compounds and breaks the microbial bonds holding the matrix together.This disrupts bacterial colonies and allows for the complete dislodging and removal of the biofilm from pipe surfaces and dripper orifices. Importantly, chlorine dioxide works across a wide pH range, from 5 to 9, making it ideal for greenhouse fertigation systems that operate under slightly alkaline conditions.

Unlike ozone, which is unstable in water, or sodium hypochlorite, which loses effectiveness in high-pH environments, chlorine dioxide maintains efficacy without forming hazardous chlorinated by-products. It also leaves behind fewer residuals—primarily chlorite, which is easier to monitor and manage.

This ability to disinfect without forming harmful by-products, while still preserving the integrity of drip system components, makes chlorine dioxide an ideal solution for cannabis growers looking to balance crop safety, operational efficiency, and regulatory compliance.

Cannabis Greenhouse Conditions That Accelerate Clogs

Cannabis greenhouses offer a hybrid of natural and controlled growing environments — but they also present ideal conditions for biofilm development. Heat, humidity, nutrient-rich water, and long irrigation cycles all create an environment where bacteria and other microorganisms can thrive.

Biofilm formation is especially rapid when drippers operate at low pressure or remain idle between cycles. Moisture and residual nutrients inside the lines encourage microbial adhesion, while mineral deposits (calcium, iron, and magnesium) create rough surfaces where biofilm can anchor and grow. When chemical reactions from dissolved fertilizers or organic matter occur, they can further contribute to fouling and scale buildup within the system.

Cannabis production adds another layer of complexity. The plants themselves are high-value and sensitive, requiring consistent hydration and nutrient delivery to maintain terpene and cannabinoid profiles. A clogged emitter doesn’t just reduce yield — it can alter plant health and delay harvest schedules, threatening product consistency in both recreational marijuana and medical cannabis markets.

These factors make biofilm control not just a maintenance task, but a core part of greenhouse operations. And in a facility where even short-term irrigation failures can disrupt entire crop cycles, proactive treatment with a chlorine dioxide generator becomes essential.

Chlorine Dioxide Generator Methods

Because chlorine dioxide is a gas that can’t be stored safely in high concentrations, it must be produced on-site using precursor chemicals. For cannabis greenhouse operations, the choice of chlorine dioxide generator method directly impacts safety, cost, and system compatibility.

EAI offers several chlorine dioxide generator technologies, including electrochemical, 2-chemical acid-chlorite, and 3-chemical (acid-chlorite-hypochlorite) systems. Each has distinct benefits depending on system size, flow rate, and regulatory considerations.

- Electrochemical Chlorine Dioxide Generators (Electricide® CDE): These systems generate ClO₂ using sodium chlorite and electricity—no acid or chlorine gas required. They produce high-purity chlorine dioxide (95–99%) and offer greater than 80% chlorite conversion, minimizing waste and residual chemicals. With fewer moving parts, these units are ideal for facilities that prioritize reliability and chemical handling safety, with only sodium chlorite as the precursor.

- 2-Chemical Systems (CD2D/CD2C): By reacting hydrochloric acid with sodium chlorite, these systems offer a compact, cost-effective solution for lower-volume applications. While chlorite yield is around 65–68%, the simplicity of the process makes it popular for mid-sized cannabis operations.

- 3-Chemical Systems: These use a blend of sodium chlorite, hydrochloric acid, and sodium hypochlorite to achieve over 95% conversion efficiency. However, this process introduces trace amounts of free chlorine, which may not be acceptable in systems that require low by-product formation.

All EAI ClO₂ generators are designed for continuous or contiguous operation and chlorine dioxide production in the cannabis industry, depending on how the facility applies water treatment. Whether dosing directly into fertigation lines or maintaining storage tanks with chlorine dioxide solution, these systems offer flexible integration and precise control.

Learn more about EAI’s chlorine dioxide generators.

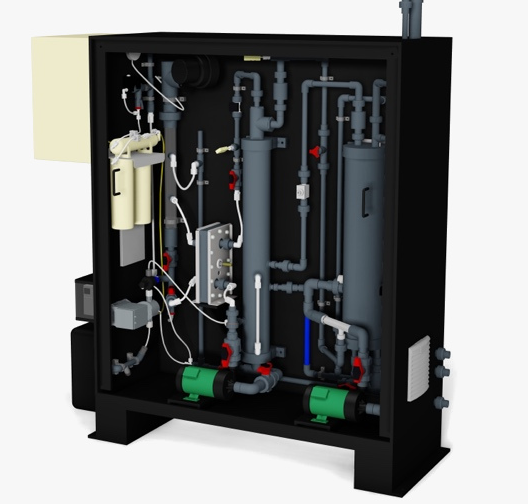

EAI’s System for the Cannabis Industry

For cannabis producers facing persistent irrigation issues, EAI delivers a ClO₂ solution designed specifically for greenhouse environments. EAI engineers and services onsite chlorine dioxide generators that are both scalable and compliant — ideal for maintaining biofilm-free fertigation systems in high-value crops such as medical marijuana.

EAI’s generator systems are built using single-chemical or dual-chemical precursor technologies, minimizing chemical handling risks while maximizing disinfection precision. Whether it’s a low-volume dripper system or a large-scale facility with complex recirculation loops, EAI customizes equipment and dosing strategies for the exact water chemistry, chemical compounds, and flow conditions of each site.

EAI’s chlorine dioxide generators are also compact and modular, meaning they can be installed alongside existing nutrient injection and water treatment infrastructure. These chlorine dioxide generators offer real-time monitoring, automated dosing, and precise flow pacing. That is critical for growers who can’t afford emitter clogs or nutrient disruption during peak flowering stages.

For cannabis companies operating in regulated markets, EAI’s ClO₂ approach ensures full alignment with safety standards while minimizing the formation of regulated disinfection by-products. In short, it’s a smarter way to protect your irrigation system, your plants, and your business.

Regulatory and Environmental Considerations

Legal cannabis industry expands, and so does the pressure to operate sustainably and within strict regulatory frameworks. From air emissions and odor control to wastewater discharge and water disinfection, compliance is a foundational part of doing business.

Chlorine dioxide is a commonly utilized solution that offers a significant advantage in this space. Unlike chlorine gas or sodium hypochlorite, chlorine dioxide doesn’t produce trihalomethanes (THMs) or high levels of adsorbable organic halides (AOX), both of which are tightly regulated in municipal water systems. This makes chlorine dioxide an ideal treatment option for cannabis facilities that discharge to public sewers or recycle water on-site.

Environmentally, chlorine dioxide is a cleaner chemistry. A 2021 study published in Nature Sustainabilityfound that greenhouse cannabis production can emit over 2,200–5,100 kg of CO₂-equivalent per kilogram of dried flower — much of it from HVAC and environmental controls. While ClO₂ can’t solve lighting or heating emissions, it can reduce the energy and chemical load of biofilm control systems by replacing high-frequency flushing, acid washes, and reactive chemical cocktails.

Most importantly, chlorine dioxide use helps protect public health by ensuring that water used in cannabis operations (whether for fertigation or product cleaning) meets disinfection standards without compromising downstream ecosystems or violating discharge permits.

Operational Best Practices for ClO₂ in Cannabis Greenhouses

Implementing chlorine dioxide in a cannabis greenhouse requires integrating a complete disinfection strategy that supports system performance and plant health.

1. Dose Smartly, Not Excessively

Chlorine dioxide is powerful even at low concentrations. A typical application for biofilm prevention in irrigation systems ranges from 0.5 to 2.0 ppm, depending on system size and water quality. Overdosing doesn’t improve results—it may unnecessarily raise chlorite levels, which are regulated in many jurisdictions.

2. Maintain Line Cleanliness

For best results, chlorine dioxide should be introduced into fertigation or irrigation lines regularly during low-flow cycles or overnight recirculation periods. This allows sufficient contact time with biofilm. Periodic system flushing is still recommended, but much less frequent than in traditional chlorine-based programs.

3. Monitor Residuals Effectively

Using DPD1 reagents, operators can quickly measure chlorine dioxide in treated water. For systems where chlorine might also be present, Lissamine Green B is preferred—it’s chlorine-independent and gives an accurate ClO₂-only reading.

4. Pair with Compatible Materials

Chlorine dioxide is compatible with most greenhouse piping and emitter materials (as well as cooling towers), especially when generated at high purity. However, chlorine-chlorite generation methods may introduce free chlorine, which can degrade some plastics over time. EAI’s electrochemical and 2-chemical systems help mitigate this by keeping unwanted chemical by-products to a minimum.

5. Document and Automate

Modern cannabis greenhouses benefit from automation. EAI’s dosing systems can be linked with existing flow pacing tools or moisture sensors, ensuring consistent, need-based treatment. For facilities pursuing GMP certification or third-party audits, digital logs of chlorine dioxide use support both compliance and traceability.

By following these practices, growers gain the benefits of chlorine dioxide biofilm control (fewer clogs, longer equipment life, and more uniform irrigation) disrupting their day-to-day operations.

Stop the Clogs Before They Start: Smarter Biofilm Control with ClO₂

Clogged emitters, uneven watering, and biofilm buildup don’t have to be business as usual in cannabis greenhouses. With chlorine dioxide biofilm control, growers gain a powerful, pH-independent disinfectant that protects their irrigation systems without compromising compliance or crop quality.

EAI’s onsite chlorine dioxide systems make biofilm prevention simple, safe, and scalable.Talk to an EAI expert about integrating chlorine dioxide into your fertigation or greenhouse irrigation plan.