Intermittent Water Supply: Microbial Risk in Data Center Operations

From cloud computing and AI to banking and logistics, data centers are fueling exponential growth in digital services. Yet behind the sophisticated server racks and advanced cooling loops lies dependence on a continuous water supply. And when that water becomes unreliable or unavailable, the consequences ripple through every layer of operation.

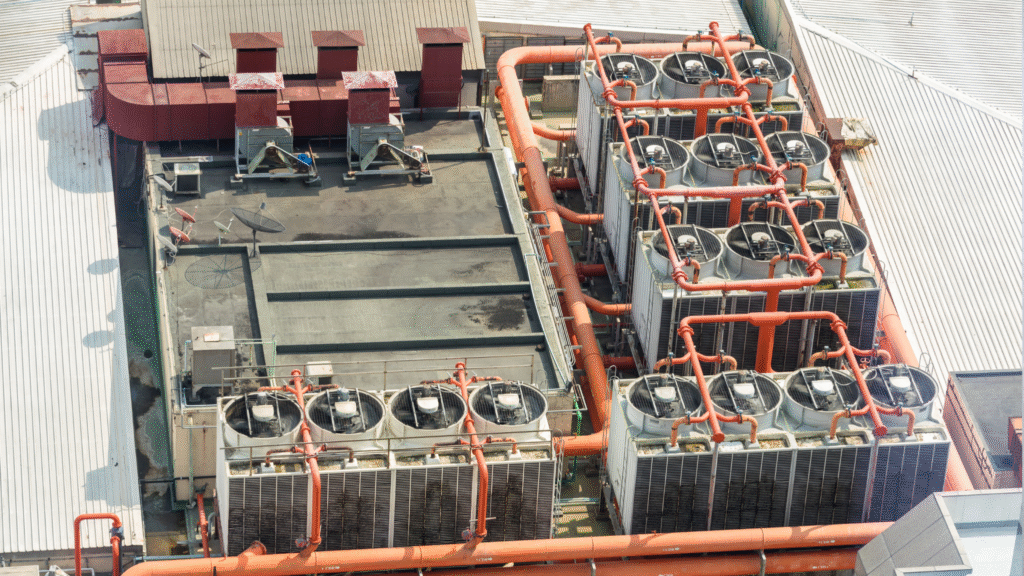

Intermittent water supply poses a serious threat to the uptime, efficiency, and thermal regulation of data centers. Facilities that rely on continuous water supplies for cooling towers, humidification, and power generation face system-wide vulnerabilities when service is inconsistent. In fact, the very infrastructure designed to support non-stop data flow can become destabilized by irregular water quality, pressure loss, or delayed sanitation protocols.

As part of EAI’s “The Water Industry is All Industry” campaign, this article explores how intermittent supply impacts water-dependent systems in data centers, why it’s a growing concern, and how strategic water management such as chemical treatment, storage planning, and remote monitoring can prevent small failures from becoming catastrophic.

Why Intermittent Water Supply is a Data Center Vulnerability

Modern data centers are designed around the assumption of continuous supply; not just of power, but also of water. This water runs through cooling towers, pumps, and humidification systems, ensuring that heat generated by servers doesn’t lead to shutdowns or fire risks. But when water supply systems falter, even temporarily, that assumption collapses.

Intermittent supply can result from:

- Aging municipal distribution systems

- Infrastructure repairs or pipeline leakage

- Seasonal demand surges and climate-related drought

- Emergency maintenance or contamination events

- Allocation of non-potable water supplies to municipal drinking water needs

Each disruption, even one lasting a few hours, can impair the loop between heat generation and dissipation. This will cause temperature spikes and operational alarms. And over long periods, these stressors accelerate wear on components like pipes, pumps, and filtration media, making the system harder to maintain.

Microbial Growth in Stagnant Water Systems: An Invisible Threat

When water stagnates in a system, it sets the stage for microbial growth. Think of cooling tower basins or storage reservoirs that experience periods of low flow or total shutdown. These environments create ideal conditions for bacteria, microbes, and other organisms to colonize surfaces, forming robust biofilms.

In batch culture studies where bacteria are grown under controlled lab conditions, scientists have identified various stages of microbial development:

- Lag phase – Microbes adapt to the environment.

- Exponential phase (log phase) – Rapid cell division and increase in cell number.

- Stationary phase – Growth slows as nutrients deplete.

- Decline phase – Cell death outpaces growth due to toxic byproducts.

This same cycle can occur in industrial water supply systems, especially when continuous flow is interrupted or pumps are shut off. Water left stagnant in pipes promotes biofilm formation, a sticky matrix of cells, enzymes, and extracellular polymeric substances that resists both flow and disinfection.

This results in a sharp decrease in water quality, elevated health risks, and costly sanitization efforts to restore baseline conditions.

The Biological Risk Behind Intermittent Supply in Cooling Systems

In data centers, water is not only a thermal transfer medium but also a microbial habitat. When water flow is inconsistent, stagnant pockets form in pipes, storage tanks, and distribution systems. These environmental conditions can promote the development of bacterial populations, especially in cooling tower basins and condenser loops where temperatures and nutrients create ideal conditions for microbes to thrive.

Pathogens like Legionella are especially concerning in open-loop water supply systems. According to OSHA and CTI, continuous feed of chlorine or bromine is often recommended to maintain microbial control. However, the ideal halogen concentration is still debated. Too little halogen fails to suppress microbial activity; too much can damage infrastructure. This delicate balance becomes harder to maintain when an intermittent water supply leads to decreased flow, leakage, or system stagnation.

Cooling Towers as a Microbial Reservoir

Cooling towers, common in HVAC systems for data centers, have been identified as high-risk environments for waterborne pathogens. A year-long study published by the National Center for Biotechnology Information found that while cooling tower water contains bacterial taxa similar to those in freshwater or drinking water, their semi-open design and seasonality contribute to highly dynamic microbial communities. These include not only bacteria but protists, which act as hosts and amplifiers for pathogens.

A network analysis from the study revealed that organisms such as Pseudomonas, Mycobacterium, and Legionella formed persistent biofilms on surfaces within the towers. Once established, these biofilm matrices become extremely difficult to remove, shielding microorganisms from disinfectants and promoting microbiologically-influenced corrosion (MIC). This has been a leading cause of infrastructure damage in both open and closed systems.

MIC is often driven by slime-forming cells that increase corrosion rates, particularly during long periods of poor circulation. In essence, stagnation not only encourages bacterial growth, it directly attacks metal surfaces in the system, compromising cooling efficiency and structural integrity.

How Pathogens Enter the System

The EPA identifies numerous pathways through which pathogens can enter distribution systems, including leaking pipes, backflow during low-pressure events, improperly cleaned equipment, and unsealed storage. These breaches allow bacteria, fungi, and other organisms to embed within biofilms and survive even during chemical treatment. Once embedded, bacteria shift from a log phase of cell division to a stationary phase where new cells slow. However, microbial defense and enzyme production increases, making disinfection significantly harder.

This aligns with the biological pattern seen in batch culture studies, where cells transition through predictable stages: lag phase, exponential phase, stationary phase, and decline phase. In data center systems, intermittent supply often stalls microbial progression at the biofilm-resistant stationary phase, where they’re neither growing rapidly nor dying, just entrenched.

How EAI Supports the Data Center Industry

At EAI Water, we understand that uptime is everything in the data center industry. Behind every cooling loop, turbine, or boiler lies the need for better water quality. We understand that in an industry where temperature control, operational continuity, and equipment longevity hinge on reliable performance, even a brief interruption in water supply can introduce unacceptable operational risk.

That’s why we provide comprehensive support to data centers through proactive water treatment programs, engineered system design, and around-the-clock technical service. Whether you’re concerned about microbial intrusion, scale formation, or corrosion in high-pressure environments, our team tailors solutions that reduce exposure, protect infrastructure, and maintain efficiency.

We don’t just apply chemical programs, we integrate process-driven strategies to address everything from continuous supply assurance to biofilm control and energy optimization.

What We Deliver to Data Centers:

- Pretreated water for boilers and cooling towers: Clean, conditioned water helps prevent scaling, fouling, and microbial growth in your most sensitive equipment.

- Remote monitoring and routine service plans: Real-time measurements and on-site inspections help prevent issues before they occur, especially in mission-critical systems where continuous performance is expected.

- Protection for process assets: Our treatment strategies are designed to prolong the lifespan of pumps, condensers, and system components by minimizing corrosive and microbial impacts.

- Custom filtration systems: EAI engineers modular, scalable systems such as reverse osmosis, ultrafiltration, electrodeionization (EDI), and enclosed container skids to match the demands of modern server cooling infrastructure.

- Onsite water reclamation and reuse: Reduce demand on municipal sources and avoid surcharges with engineered loop reuse of blowdown water and condensate recovery systems.

Learn more about our water treatment for energy and power services.

We also support natural gas and combined cycle facilities supplying power to hyperscale and colocation centers. This ensures that both energy generation and data operations stay clean, efficient, and compliant.

As one of the Unite most experienced locally owned water treatment providers, EAI is proud to serve the evolving needs of data center operators. From emergency response to regulatory compliance, we provide confidence through chemistry, engineering, and service.

Stay Ahead of Water Risks in a 24/7 Industry

Data centers don’t get to pause. Neither should your water treatment strategy. From temperature spikes caused by intermittent water supply to long-term damage from microbial contamination or corrosion, the risks tied to water quality are real and preventable. Whether you’re running hyperscale infrastructure or managing a regional facility, building resilience starts with visibility, consistency, and expert partnership.

EAI offers data center operators a smarter path forward: with real-time monitoring, tailored treatment plans, and expert support that adapts as your systems evolve.

Want to improve system reliability, reduce risk, and build long-term sustainability into your water infrastructure?

Contact EAI to schedule an on-site review and receive a customized water treatment strategy for your facility.

Frequently Asked Questions

1. What makes intermittent water supply a bigger issue for data centers than other industries?

Data centers operate continuously and require precise temperature control. Even brief disruptions in water supply can compromise cooling systems, triggering alarms or forcing shutdowns.

2. Can intermittent supply lead to contamination in closed-loop systems?

Yes. Even in closed systems, stagnation from reduced flow can allow microbes to multiply, especially in dead legs or low-flow areas, forming biofilms that resist disinfection.

3. How does EAI help prevent microbiological growth in cooling towers?

We implement tailored chemical programs and filtration strategies designed to disrupt microbial cell division, remove nutrients, and prevent biofilm formation in high-risk areas.

4. What are the signs of microbiologically-influenced corrosion (MIC)?

Indicators include localized pitting, uneven corrosion patterns, and rapid component degradation. MIC is often accelerated by slime-forming bacteria present in biofilm matrices.

5. Can EAI help reduce my facility’s reliance on municipal water?

Yes. EAI offers onsite reclamation systems that reuse blowdown or process water to support continuous supply, helping reduce costs, water demand, and environmental impact.