How to Perform a Reverse Osmosis Membrane Replacement

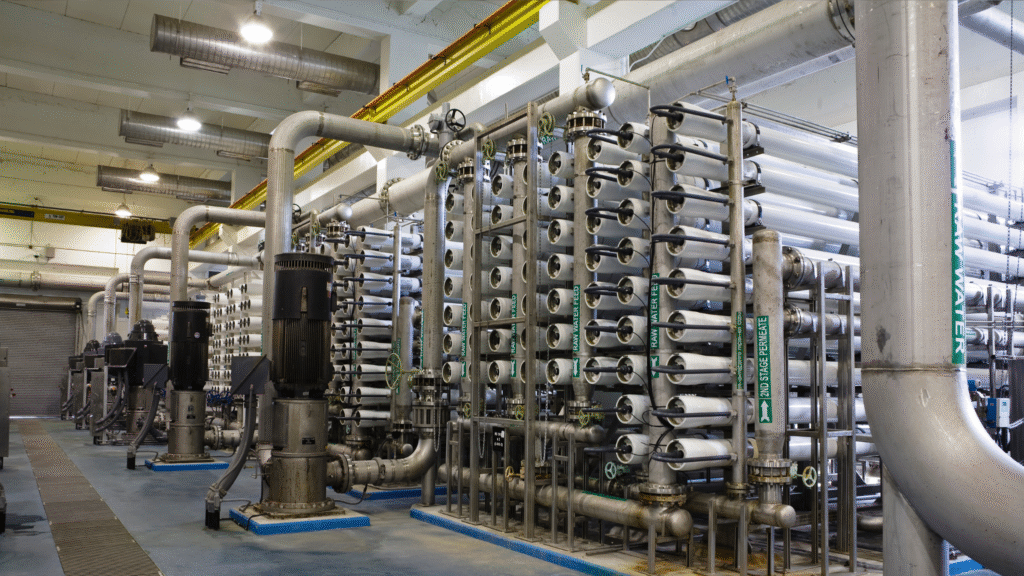

In any reverse osmosis (RO) system, the reverse osmosis membrane is the heart of the operation—responsible for removing dissolved solids (TDS), heavy metals, bacteria, and other contaminants from your water. Over time, however, even the highest-quality membranes wear down and foul, leading to reduced performance, poor water quality, and higher TDS levels. That’s why timely RO membrane replacement is critical for maintaining system efficiency and protecting your investment.

A failing RO membrane can quietly compromise your system’s output without obvious warning until issues like bad taste, foul odors, or reduced water production appear. Knowing when and how to perform a proper membrane replacement not only ensures continued access to high-quality water, but also helps extend the life of your system’s filters, pumps, and tubing connections.

At EAI, we specialize in designing and supporting high-performance RO systems built for reliability, efficiency, and long-term results. In this guide, we’ll walk you through the full membrane replacement process, explain common signs of failure, and share expert tips for keeping your RO system performing at its best.

Signs You Need a Reverse Osmosis Membrane Replacement

Even with regular maintenance, every reverse osmosis membrane eventually reaches the end of its service life. Exposure to contaminants like chlorine, heavy metals, bacteria, and sediment gradually reduces reverse osmosis filtration performance. Recognizing these early warning signs can help you schedule a timely replacement process — and avoid costly system damage.

Look for these clear indicators:

- TDS readings are consistently high despite recent filter changes, even after flushing your RO system. A healthy membrane should maintain low total dissolved solids measured with a TDS meter.

- Poor taste, odor, or visible particles appearing in your drinking water suggest the membrane is no longer effectively rejecting impurities like lead, arsenic, fluoride, or organic matter.

- Reduced water production at the makeup water connection can indicate membrane clogging or structural damage within the membrane housing.

- Frequent leaks around tubing connections or the membrane housing could signal pressure imbalances caused by a degraded or improperly seated membrane.

Tip: Using a TDS meter regularly helps monitor membrane health, catch declining performance early, and ensure you’re maintaining the best possible water quality.

What You’ll Need Before Starting

Before beginning your reverse osmosis membrane replacement, it’s important to gather the right tools and materials. Having everything prepared ahead of time helps ensure a smooth process, prevents unnecessary system downtime, and reduces the risk of damaging components like tubing connections or o-rings.

Here’s a checklist of what you’ll need:

Essential Tools and Supplies

- New reverse osmosis filters: Make sure you purchase a membrane that is compatible with your RO system. Check specifications carefully to match the system size and operating pressure.

- Needle nose pliers: Useful for gripping and removing the old membrane safely from the membrane housing.

- TDS meter: This tool allows you to measure dissolved solids before and after the replacement to confirm improved water quality.

- Tubing cutter or sharp blade: If you need to replace or adjust any tubing connections, clean cuts are essential to avoid leaks.

- Clean o-rings: Inspect and replace o-rings if they are worn, cracked, or dirty. Proper sealing is critical to avoid leaks after installation.

- Housing wrench: Some systems require a special wrench to open or tighten the membrane housing cap securely.

Additional Helpful Items

- Food-grade silicone lubricant: A small amount on o-rings can make reassembly easier and help create a better seal.

- Bucket or towels: To catch any water that spills during disassembly.

- New filters (if scheduled): If you are already planning a full RO system service, it’s a good time to replace your prefilters and postfilters too.

Pro Tip: Always check that you have the correct stock of replacement parts Monday–Friday before starting a project. It can be harder to find compatible membranes or o-rings over the weekend if you realize you’re missing something.

By ensuring you have all necessary components and tools on hand, you can perform a reverse osmosis membrane replacement efficiently and avoid unexpected delays. Plus, proper preparation helps protect your system’s tubing, housing, and filter seals during the process.

Step-by-Step Guide to RO Membrane Replacement

Performing a reverse osmosis membrane replacement isn’t complicated when you break it down into clear steps. By following these instructions carefully, you’ll protect your RO system, maintain water quality, and extend the lifespan of other critical components like filters, tubing, and fittings.

Step 1: Shut Off the Water Supply and Power

Locate your RO system, typically installed in a mechanical room, equipment area, or dedicated utility space within your facility.

- Close the feed water valve that supplies water to the unit.

- Shut off the storage tank valve to prevent backflow.

- If your system uses electricity (for a UV light, control system, or booster pump), unplug or disable power sources before starting.

This ensures that no water pressure or electrical energy remains in the system while you work.

Step 2: Drain the System

Open the RO faucet to relieve any built-up pressure. Allow the water to drain completely from the system and tubing connections.

Use a towel or small bucket to catch any remaining water around fittings and membrane housing areas.

Step 3: Access the Membrane Housing

Find the cylindrical membrane housing on your RO unit — it’s typically white or translucent and horizontal in orientation.

- Remove any securing clips or fasteners if present.

- Using a housing wrench, carefully loosen and remove the housing cap.

Take your time during this step. Over-tightening or forcing the cap can damage threads, o-rings, or cause leaks after reassembly.

Step 4: Remove the Old Membrane

With the cap off, you’ll see the existing RO membrane seated inside the housing.

- Use needle nose pliers to gently grip the end of the membrane.

- Pull the membrane out with firm, steady pressure.

It may feel snug — this is normal. Be careful not to damage the inside of the housing during removal.

Dispose of the old membrane properly according to local regulations.

Step 5: Inspect and Prepare for Installation

Before inserting your new RO membrane, take a few minutes to:

- Clean the inside of the membrane housing if you see any sediment, particles, or biofilm buildup.

- Inspect all o-rings for wear, cracks, or flattening.

- Replace old o-rings if necessary, applying a light coat of food-grade silicone lubricant to aid seating.

Checking these small parts helps prevent leaks and ensures the new membrane fits correctly.

Step 6: Insert the New Membrane

Now it’s time to install your new membrane:

- Confirm your new RO membrane is compatible with your unit (model, flow rate, and size).

- Insert the membrane into the housing, pushing firmly until it is seated correctly.

- You should feel a distinct “push” when the membrane connects properly to the internal connector.

- Replace the housing cap securely, being careful not to overtighten.

Tip: Always double-check that tubing connections and fittings around the housing are aligned properly during reassembly.

Step 7: Reconnect the System and Flush

After installing the new membrane:

- Reopen the feed water valve and storage tank valve if present.

- Allow the system to flush thoroughly according to manufacturer guidelines, discarding sufficient water (typically 10–15 gallons or more) to remove any preservative chemicals from the new membrane.

The flushing process conditions the new membrane and ensures that the system delivers clean, high-quality water.

Use a TDS meter to check the initial filtered water:

- You should see significantly lower total dissolved solids (TDS) compared to pre-replacement readings.

- If TDS remains high after several gallons, continue flushing until the water quality stabilizes.

Step 8: Check for Leaks and Final Test

Inspect all tubing connections, membrane housing, and fittings:

- Look for any slow drips or leaks.

- Tighten or reposition any connections if necessary.

Test the system again after a few hours of run time to confirm stable operation and excellent water quality.

Quick Tips for a Smooth Membrane Replacement

- Never force tubing into fittings — align and push gently but firmly.

- Always confirm that the new membrane is compatible with your system specs.

- Replace any old or worn filters during membrane replacement if nearing end of life.

- Keep a small stock of spare o-rings and tubing on hand for easier maintenance.

- If you notice persistent leaks or high TDS after proper installation, contact a professional service provider.

Troubleshooting Common RO Membrane Replacement Issues

Even with a careful reverse osmosis membrane replacement, small issues can sometimes affect system performance. Use this quick troubleshooting guide to identify and resolve the most common problems:

| Issue | Signs | Likely Cause | Solution |

|---|---|---|---|

| Leaks around tubing or housing | Water dripping from tubing connections, fittings, or the membrane housing | Loose fittings, damaged o-rings, or overtightened housing cap | Re-seat tubing correctly, inspect and replace o-rings, tighten the housing cap gently without overtightening |

| High TDS after new membrane | TDS meter shows high total dissolved solids readings even after membrane replacement | Preservative chemicals from new RO membrane, incomplete flushing | Perform a full system flush (discard 10–15 gallons), then recheck with TDS meter |

| Bad taste or odor in water | Water has unusual taste, odor, or quality water issues after installation | Overdue RO filters (carbon, sediment), residual chlorine or organics | Replace prefilters and postfilters along with membrane to restore water taste and odor |

| Slow water production | Low flow rate at kitchen sink faucet or refrigerator line | Incorrect tubing connections, feed water pressure too low, clogged tubing or housing | Check tubing for kinks, ensure minimum inlet pressure, confirm housing assembly and flush the system completely |

| Membrane not seated correctly | Continued poor filtration performance after membrane install | New membrane not seated correctly inside housing | Remove and insert membrane again firmly, ensuring a full push into position for proper sealing |

Pro Tip: After completing membrane installation, always monitor your system for leaks, TDS levels, and water taste during the first few days of use to catch any issues early.

How Often Should You Replace an RO Membrane?

A reverse osmosis membrane is designed for durability, but like any critical filtration component, it has a limited service life. Knowing when to schedule a reverse osmosis membrane replacement helps maintain consistent water quality and extends the life of your RO system overall.

Typical Replacement Timeline

Most residential and light commercial RO membranes should be replaced every 2 to 5 years depending on a few key factors:

- Water Quality: High concentrations of chlorine, heavy metals, bacteria, and sediment in the feed water can wear out a membrane faster.

- System Usage: The more water your RO system produces daily, the harder the membrane works, which can shorten its lifespan.

- Total Dissolved Solids (TDS): Higher incoming TDS levels put additional stress on the membrane during the osmosis process, meaning it may need to be replaced sooner.

- Filter Maintenance: Regularly replacing your RO filters — especially the carbon prefilter — helps protect the membrane by removing chlorine and particulates that could cause damage.

If the system is properly maintained and water conditions are favorable, a high-quality new membrane can easily last four years or longer.

Why Trust Professional Service for RO Membrane Replacement?

Replacing a reverse osmosis membrane may seem straightforward, but small mistakes can lead to major system problems. From incorrectly seated membranes to damaged tubing connections or leaks inside the membrane housing, even a minor installation error can compromise water quality, cause persistent leaks, or shorten system life.

That’s why many facilities and homeowners trust professional service providers like EAI Water for critical RO membrane replacements.

Benefits of Professional Installation

- Correct Membrane Matching: EAI technicians ensure your new membrane is fully compatible with your system’s specifications, flow requirements, and water chemistry.

- Secure Installation: Proper seating of the membrane, inspection of o-rings, and careful connection of all tubing and fittings eliminates common causes of leaks.

- Full System Testing: After replacement, the entire system is checked for pressure balance, flow rate, and TDS removal performance using calibrated equipment like a TDS meter.

- Preventive Recommendations: If additional issues are found (such as worn filters, clogged tubing, or failing valves), EAI provides expert advice to restore your system to peak condition.

- Time Savings: With professional installation, you save valuable time and avoid trial-and-error troubleshooting that can occur during DIY membrane replacement.

- Emergency Support: Should an issue arise after replacement, EAI offers rapid-response service to correct problems quickly and protect your water supply.

When it comes to protecting your investment in clean, purified drinking water, working with an experienced service provider ensures a proper membrane installation, high-quality performance, and peace of mind for years to come.

Keep Your RO System at Peak Performance

A clean, properly installed membrane is the heart of any reverse osmosis system. If it’s time for your reverse osmosis membrane replacement, don’t leave water quality to chance. EAI Water provides expert membrane installation, system testing, and long-term support to keep your RO system running smoothly.

Contact us today to schedule your membrane replacement or to learn more about how we can help you maintain high-performance, high-purity water every day.