Explore the Various Cooling Tower Types for Your Facility

Cooling towers are essential for managing heat in industrial, commercial, and HVAC applications, directly impacting system efficiency, water consumption, and operational costs. Choosing the right cooling tower is critical to ensuring long-term performance, minimizing maintenance demands, and optimizing energy use.

While all cooling towers serve the same fundamental purpose—removing excess heat from a facility’s cooling system—they vary significantly in design, airflow configuration, heat exchange method, and water efficiency. The best choice depends on factors such as cooling load, climate conditions, space constraints, and maintenance capabilities.

At EAI Water, we specialize in helping facilities select, maintain, and optimize their cooling tower systems. Learn more about our support services at Facility Operator Support.

Cooling Tower Classifications

Cooling towers are categorized based on:

- Airflow Configuration: How Air Moves Through the System

- Natural draft vs. mechanical draft cooling towers

- Forced vs. induced draft designs

- Efficiency, space, and energy trade-offs

- Heat Exchange Configuration: Crossflow vs. Counterflow Cooling Towers

- How air and water interact inside the system

- Performance and maintenance considerations

- Direct comparison of efficiency and space requirements

- Hybrid Cooling Towers and Advanced Innovations

- Combining wet and dry cooling for optimized performance

- Smart monitoring and AI-driven efficiency improvements

- Water Efficiency and Maintenance Best Practices

- Key water conservation strategies

- Challenges in managing scaling, drift, and blowdown

- Selecting the Right Cooling Tower for Long-Term Success

- How to match the right system to your facility’s needs

- Real-world case study and action steps

Cooling towers represent a long-term investment in facility performance, and selecting the right system impacts energy costs, maintenance demands, and regulatory compliance.

The first major classification is airflow configuration, which determines how air circulates through the cooling tower. The next section explores the differences between natural draft and mechanical draft cooling towers, outlining their efficiency, space requirements, and ideal applications.

Airflow Configuration – How Air Moves Through the System

Cooling tower performance depends on how air moves through the system, affecting heat rejection efficiency, energy consumption, and space requirements. Airflow configuration is a key classification that determines whether a cooling tower relies on natural convection or mechanical assistance to circulate air.

Natural Draft Cooling Towers

Natural draft cooling towers use the chimney effect to move air without the need for fans. Warm air inside the tower rises naturally due to density differences, drawing in cooler air from below.

Best For

- Large industrial facilities and power plants that require high-capacity cooling

- Facilities with space to accommodate large hyperbolic or cylindrical towers

Advantages

- No fan power consumption, leading to lower operating costs

- Fewer moving parts, minimizing maintenance needs

Limitations

- Requires significant space due to its large structure

- Higher installation costs compared to mechanical draft systems

Mechanical Draft Cooling Towers

Unlike natural draft systems, mechanical draft cooling towers use fans to actively circulate air, allowing for greater control over cooling performance. These towers are more compact and adaptable to different site conditions.

Mechanical draft towers are divided into forced draft and induced draft systems.

A. Forced Draft Cooling Towers

- How they work: Fans are positioned at the base, pushing air through the system.

- Advantages: Compact design, suitable for small or enclosed spaces.

- Limitations: Higher risk of air recirculation, reducing efficiency.

B. Induced Draft Cooling Towers

- How they work: Fans are placed at the top, pulling air upward through the tower.

- Advantages: More efficient than forced draft due to reduced recirculation.

- Limitations: Requires taller structures, which may not be suitable for all facilities.

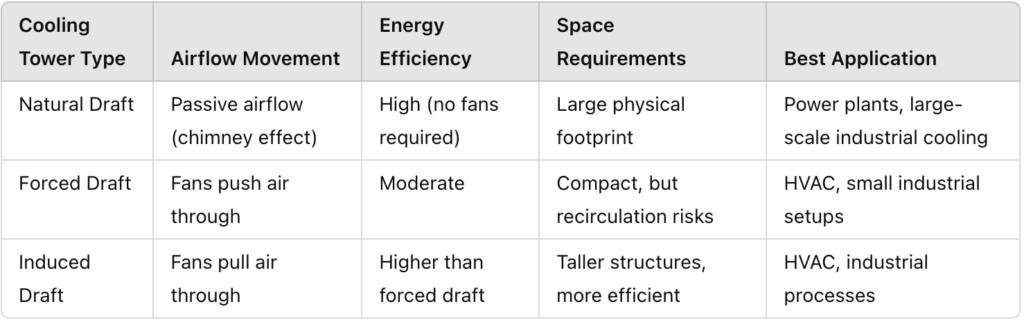

Comparison: Natural vs. Mechanical Draft Cooling Towers

Choosing the Right Airflow Configuration for Your Facility

Selecting the right airflow configuration depends on:

- Facility size and available space – Natural draft requires large areas, while mechanical draft towers can fit compact sites.

- Energy efficiency goals – Natural draft eliminates fan power consumption but has high initial costs.

- Cooling demand and control requirements – Mechanical draft towers provide more flexibility in adjusting cooling capacity.

Airflow configuration is only one part of the cooling tower selection. The next section explores heat exchange design—crossflow vs. counterflow—and how air and water interact within the system to optimize cooling performance.

Heat Exchange Configuration – Crossflow vs. Counterflow Cooling Towers

Cooling towers are also categorized based on how air and water interact inside the system to transfer heat. This classification directly affects cooling efficiency, space requirements, and maintenance needs.

The two primary heat exchange configurations are crossflow and counterflow cooling towers. Each has distinct advantages depending on cooling demand, facility layout, and operational goals.

Crossflow Cooling Towers

Crossflow cooling towers allow water to flow vertically downward while air moves horizontally across the system. This perpendicular interaction provides a steady cooling effect while making components easily accessible.

Best For

- Facilities prioritizing ease of maintenance and lower energy consumption

- Cooling applications where space is not a constraint

Advantages

- Lower fan power requirements reduce energy consumption.

- Easier access for cleaning and routine maintenance.

Limitations

- Less efficient heat transfer compared to counterflow designs.

- Requires more space due to its larger footprint.

Counterflow Cooling Towers

Counterflow cooling towers move air vertically upward, opposing the downward flow of water. This design maximizes heat exchange efficiency, making it ideal for high-performance cooling applications.

Best For

- Compact facilities where space is limited.

- High-efficiency cooling where maximum performance is required.

Advantages

- More efficient cooling due to opposing air and water movement.

- Requires less space than crossflow designs.

Limitations

- Higher fan power requirements increase energy consumption.

- More difficult access for maintenance due to the compact internal layout.

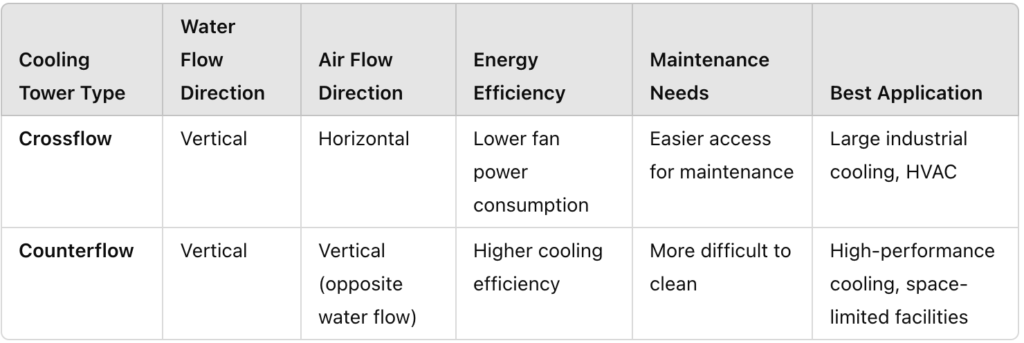

Comparison: Crossflow vs. Counterflow

Choosing the Right Heat Exchange Design

Selecting the right heat exchange configuration depends on:

- Available space – Counterflow is more compact, while crossflow requires a larger footprint.

- Energy efficiency priorities – Crossflow uses less fan power, while counterflow maximizes cooling performance.

- Maintenance needs – Crossflow is easier to maintain, while counterflow requires more effort for cleaning.

While crossflow and counterflow cooling towers define heat exchange efficiency, some facilities need more flexibility in optimizing water and energy use. Hybrid cooling towers offer a solution by integrating both wet and dry cooling methods, adjusting performance based on environmental conditions.

The next section explores hybrid cooling towers and emerging innovations, showing how advanced cooling technologies are shaping the industry.

Hybrid Cooling Towers and Advanced Innovations

While traditional cooling towers rely on either wet (evaporative) or dry (air-cooled) methods, hybrid cooling towers integrate both approaches to enhance efficiency, reduce water consumption, and improve operational flexibility. These systems can adjust their cooling method based on environmental conditions and facility needs, making them a preferred choice for facilities looking to optimize both energy and water use.

Beyond hybrid cooling, emerging technologies are reshaping cooling tower performance, introducing automation, smart monitoring, and innovative materials to further improve efficiency and sustainability.

Hybrid Cooling Towers: Combining Wet and Dry Cooling

A. How Hybrid Cooling Towers Work

Hybrid cooling towers operate in different modes depending on external conditions:

- Wet mode during high-temperature conditions, utilizing evaporative cooling for maximum heat rejection.

- Dry mode when ambient temperatures are lower, reducing water consumption while maintaining cooling efficiency.

- Hybrid mode, where water and air cooling adjust dynamically to balance performance and sustainability.

This adaptability makes hybrid cooling towers ideal for regions with strict water conservation regulations or fluctuating climate conditions.

B. Advantages of Hybrid Cooling Towers

- Lower water consumption compared to traditional wet cooling towers.

- Optimized for seasonal operation, reducing both energy and water costs.

- Minimizes drift and evaporative losses, improving sustainability and compliance with water usage regulations.

Hybrid cooling towers are increasingly used in power generation, manufacturing, data centers, and commercial HVAC applications, where both energy efficiency and water conservation are top priorities.

Emerging Technologies in Cooling Tower Systems

Advancements in cooling tower technology are providing greater control over performance, efficiency, and maintenance. Some of the most impactful innovations include:

A. Smart Cooling Tower Monitoring

- IoT-enabled sensors track real-time performance, water quality, and energy consumption.

- Automated diagnostics detect inefficiencies early, reducing downtime and operational costs.

- AI-driven optimization adjusts fan speed and water flow for maximum efficiency.

B. Adiabatic Cooling Systems

- Uses pre-cooling air mist to lower temperatures before the air reaches the heat exchanger, improving efficiency while reducing water evaporation rates.

- Offers an alternative for facilities looking to minimize water consumption while maintaining effective cooling.

C. High-Efficiency Drift Eliminators

- Reduces water loss due to misting, improving water conservation and regulatory compliance.

- New materials and designs allow for better control over airflow and water movement, improving overall efficiency.

As industries push for greater sustainability and cost efficiency, hybrid cooling towers and emerging technologies offer new opportunities to optimize cooling operations.

Cooling tower selection plays a major role in energy and water management, but additional strategies can further reduce operating costs, extend equipment lifespan, and improve compliance with environmental regulations.

The next section will explore water efficiency strategies and long-term cooling tower maintenance, including water reuse, blowdown optimization, and advanced treatment technologies to maximize system performance.

Water Efficiency and Maintenance Best Practices

Cooling towers consume a significant amount of water, making water efficiency a critical factor in operational sustainability and cost management. In addition to selecting the right cooling tower type, facilities must implement strategic water management practices to reduce consumption, prevent system inefficiencies, and comply with environmental regulations.

Beyond water conservation, proper maintenance is essential for preventing scaling, biofilm buildup, and mechanical wear—issues that can lead to reduced cooling performance and higher operational costs.

Water Efficiency Strategies for Cooling Towers

A. Optimizing Cycles of Concentration

The cycles of concentration (CoC) measure the number of times water can be reused before it must be discharged as blowdown. Increasing CoC minimizes water waste and reduces the need for fresh makeup water.

- Proper chemical treatment prevents scaling and corrosion, enabling higher CoC without reducing system performance.

- Automated water quality monitoring ensures the tower operates at optimal CoC levels without exceeding safe limits.

- Facilities that increase CoC from 3 to 6 cycles can reduce overall water consumption by up to 50%, depending on system conditions.

B. Managing Blowdown and Water Loss

Blowdown is necessary to remove accumulated minerals and impurities, but excessive blowdown leads to unnecessary water waste.

- Smart blowdown controls release only the minimum amount of water required to maintain system balance.

- Recycling blowdown water for other facility processes, such as irrigation or cleaning, further reduces waste.

- Installing high-efficiency drift eliminators prevents water loss due to misting, improving overall efficiency.

C. Using Alternative Water Sources

Many facilities are adopting non-traditional water sources to reduce dependence on fresh water.

- Rainwater harvesting can supplement cooling tower makeup water.

- Treated wastewater reuse is becoming a viable alternative, reducing reliance on municipal water supplies.

- Condensate recovery from HVAC systems helps offset cooling tower water demand.

For a deeper dive into practical water-saving techniques, read EAI Water’s guide:

Achieving Perfect Water Efficiency Starts with Small Steps.

Maintenance Best Practices for Cooling Towers

Proper maintenance is essential to keep cooling towers operating efficiently and prevent costly failures. Poorly maintained systems are prone to scaling, biological growth, and component wear, all of which reduce performance and increase energy costs.

A. Preventing Scaling and Corrosion

- Water treatment programs reduce mineral buildup, preventing scale formation that restricts heat transfer.

- Routine pH balancing and chemical dosing extend equipment lifespan and maintain operational efficiency.

B. Controlling Biological Growth and Legionella Risk

- Regular cleaning and disinfection prevent bacterial and algae growth in the cooling tower basin.

- Biocide treatments help mitigate Legionella risks and improve water hygiene.

C. Mechanical Maintenance for Longevity

- Inspecting fans, drift eliminators, and fill media ensures optimal airflow and heat transfer.

- Lubricating moving parts and checking motor efficiency reduces wear and prolongs system life.

To ensure maximum cooling tower performance and longevity, facilities should follow a structured maintenance plan that aligns with manufacturer guidelines and industry best practices.

By combining the right cooling tower selection, water efficiency strategies, and proper maintenance, facilities can significantly reduce operating costs and extend the lifespan of their systems.

The next section will provide a step-by-step guide to selecting the best cooling tower for your facility, including real-world examples and key considerations for long-term success.

Selecting the Right Cooling Tower for Long-Term Success

Selecting the right cooling tower requires balancing energy efficiency, water conservation, maintenance demands, and long-term operational costs. Facility managers must also consider environmental regulations, space constraints, and system integration to ensure the best fit for their facility.

By applying the insights from airflow configuration, heat exchange design, hybrid technologies, and water efficiency strategies, facilities can optimize performance and extend the lifespan of their cooling infrastructure.

Key Considerations for Cooling Tower Selection

A. Cooling Capacity and Efficiency Requirements

- Ensure the cooling tower can handle peak load conditions without excessive energy use.

- Counterflow and induced draft systems generally offer higher efficiency, but crossflow and forced draft towers may be preferred in space-constrained environments.

B. Space and Facility Layout

- Natural draft towers require significant space and height clearance.

- Mechanical draft towers are more compact but require proper airflow to avoid recirculation.

C. Water Usage and Environmental Regulations

- Hybrid cooling towers can help facilities meet strict water conservation policies.

- High-efficiency drift eliminators and smart blowdown control can minimize evaporative losses and chemical discharge.

D. Maintenance and Lifecycle Costs

- Consider long-term maintenance needs and accessibility for cleaning.

- Well-maintained cooling towers can last 20+ years, while neglected systems often suffer from early performance decline and costly repairs.

The Impact of Cooling Tower Optimization

Many facilities are replacing older, inefficient cooling towers with hybrid or high-efficiency mechanical draft systems to lower water usage and reduce energy costs. Common benefits seen across industrial and commercial sectors include:

- Improved water efficiency through better blowdown management and drift reduction.

- Lower maintenance costs by switching to designs that minimize scale and biofilm buildup.

- Enhanced cooling performance with AI-driven controls and real-time monitoring.

For facilities considering a cooling tower upgrade, a system evaluation can identify inefficiencies and potential cost savings.

Taking the Next Step Toward Cooling Tower Optimization

Cooling tower selection and maintenance directly impact water efficiency, energy costs, and equipment lifespan. At EAI Water, we provide customized solutions to help facility managers select, maintain, and optimize high-performance cooling towers.

For a deeper look at best practices and industry insights, download our free resource:

The New Rules of Cooling Tower Water Efficiency.

References

American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). ASHRAE Handbook – HVAC Systems and Equipment. ASHRAE, 2021.

Cooling Technology Institute (CTI). (2020). Cooling Tower Fundamentals. CTI.

U.S. Department of Energy (DOE). (2018). Cooling Towers: Understanding Key Components of HVAC Systems. DOE.

Betz Laboratories. Handbook of Industrial Water Conditioning. BetzDearborn Inc., 2000.

National Renewable Energy Laboratory (NREL). High-Performance Computing Data Center Cooling System Energy Efficiency. U.S. Department of Energy, 2019.

EAI Water. Facility Operator Support: Comprehensive Cooling Tower Optimization. EAI Water, 2024. Available at: https://eaiwater.com/facility-operator-support/.

EAI Water. Achieving Perfect Water Efficiency Starts with Small Steps. EAI Water, 2024. Available at: https://eaiwater.com/water-efficiency/.

EAI Water. The New Rules of Cooling Tower Water Efficiency. EAI Water, 2024. Available at: https://eaiwater.com/download-form-ebook-the-new-rules-of-cooling-tower-water-efficiency/.